Special vacuum cup take and place system for vacuum cup production line

A thermos cup and production line technology, applied in conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of inability to meet the needs of automated production lines, error-prone manual operations, and labor-intensive workers, to ensure conveying stability and Reliability, improve safety and reliability, save labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below in conjunction with accompanying drawing, but is not the restriction to protection scope of the present invention.

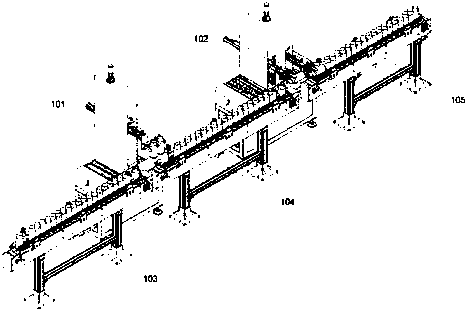

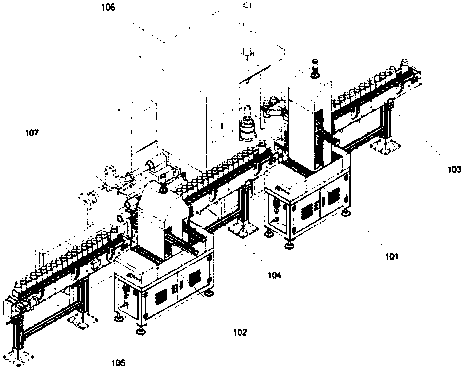

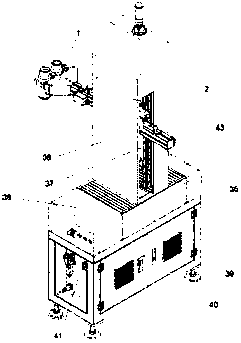

[0053] Such as Figure 1-3 As shown, a thermos cup pick-and-place system for a thermos cup production line includes a three-axis thermos cup pick-and-place device 101 that cooperates with a thermos cup mouth processing device 106, and a four-axis thermos cup pick-and-place device 102 that cooperates with a thermos cup outer wall processing device 107. , the No. 1 conveying device 103 that cooperates with the three-axis thermos cup pick-and-place device 101, the No. 2 conveyer 104 between the three-axis thermos cup pick-and-place device 101 and the surrounding thermos cup pick-and-place device 102, and the four-axis thermos cup pick-and-place device The third delivery device 105 of the device 102.

[0054] When the present invention operates, the thermos cup after the previous process is tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com