A lead zirconate titanate-based piezoelectric ceramic material with large displacement and low hysteresis and preparation method thereof

A technology of lead zirconate titanate and ceramic materials, which is applied in the field of functional ceramic materials, can solve the problems of hard piezoelectric ceramics such as polarization difficulties, and achieve the effects of high linearity, low displacement hysteresis, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the present invention comprises:

[0033] Step 1) According to Pb 1-x (Sr y Ca 1-y ) x (Zr z Ti 1-z )O 3 +aCa(Fe w Ga 1-w )O 5 / 2 +bMnO 2 General Formula for Accurately Weighing Pb in Stoichiometric Ratio 3 o 4 , SrCO 3 , CaCO 3 , ZrO 2 、TiO 2 , Fe 2 o 3 , Ga 2 o 3 and MnO 2 . Put all raw material powders into a ball mill jar, add deionized water, mix for 4 to 6 hours, pour out and dry;

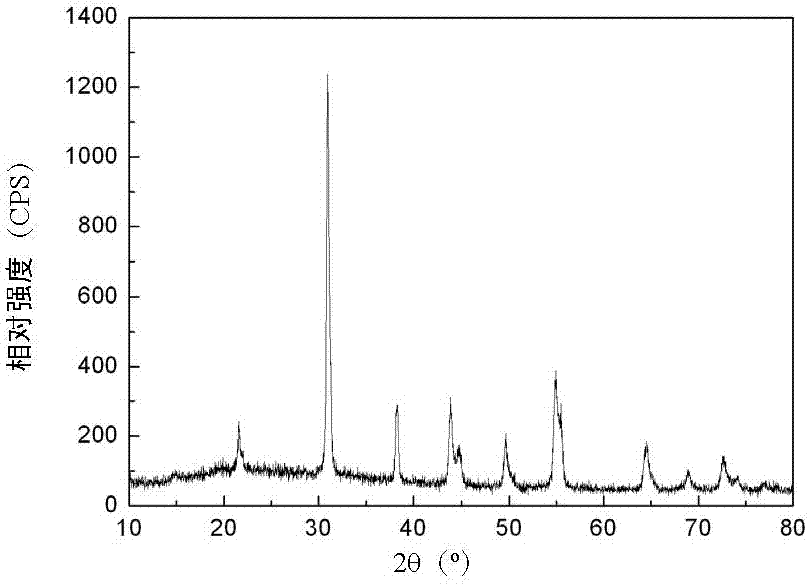

[0034] Step 2) After sieving and briquetting the uniformly mixed powder, place it in a high-temperature furnace, and synthesize it at 800-950°C for 2-4 hours to obtain the required phase;

[0035] Step 3) crush the synthesized powder, put it into a ball mill jar, add deionized water, ball mill it for 6-8 hours, pour it out and dry it;

[0036] Step 4) Adding PVA to the ball-milled powder as a binder, granulating, pressing and molding under a pressure of 150-250 MPa, and keeping the pressed green body at a temperature of 500-650°C for 2-6 ...

Embodiment 1

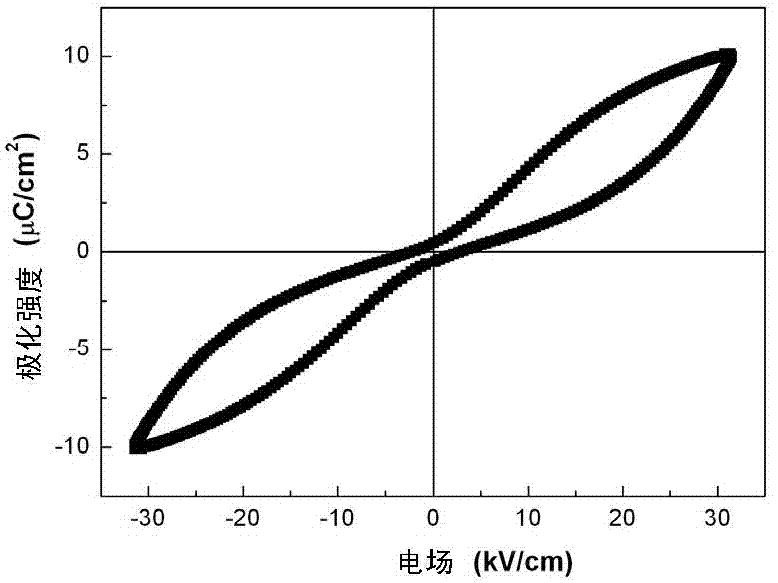

[0041] Example 1: Pb 0.90 Sr 0.05 Ca 0.05 Zr 0.53 Ti 0.47 o 3 -0.01CaFeO 5 / 2

[0042] Including the following steps:

[0043] 1) According to Pb 0.90 Sr 0.05 Ca 0.05 Zr 0.53 Ti 0.47 o 3 -0.01CaFeO 5 / 2 General Formula for Accurately Weighing Pb in Stoichiometric Ratio 3 o 4 , SrCO 3 , CaCO 3 , ZrO 2 、TiO 2 , Fe 2 o 3 . Put all raw material powders into a ball mill jar, add deionized water, mix for 4-6 hours, pour out and dry;

[0044] 2) After sieving and briquetting the uniformly mixed powder, place it in a high-temperature furnace and synthesize it at 810°C for 2 hours to obtain the required phase;

[0045] 3) Break the synthesized powder into a ball mill tank, add deionized water, and pour it out for drying after 6 hours of ball milling;

[0046] 4) adding PVA to the ball-milled powder as a binder, granulating, pressing and molding under a pressure of 200 MPa, and keeping the pressed green body at a temperature of 550° C. for 4 hours to discharge the ...

Embodiment 2

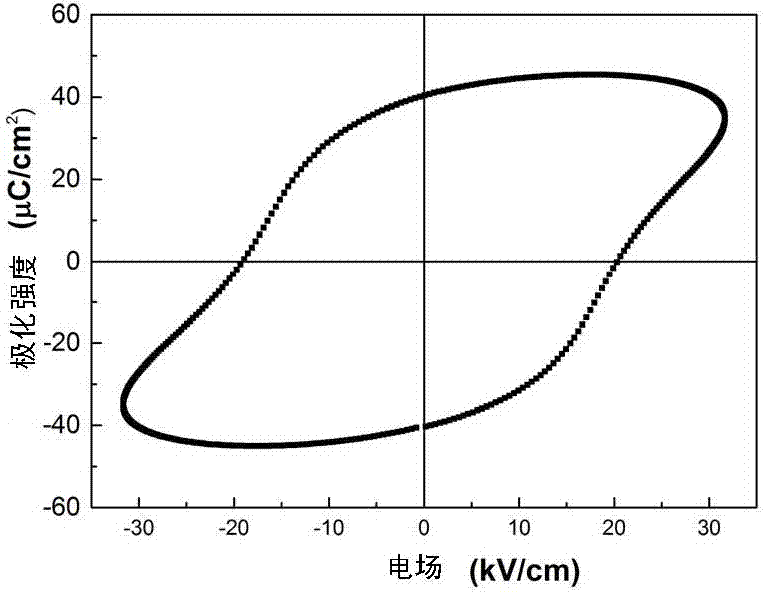

[0055] Example 2: Pb 0.90 Sr 0.10 Zr 0.53 Ti 0.47 o 3 -0.008CaFe 0.95 Ga 0.05 o 5 / 2 +0.005MnO 2

[0056] Including the following steps:

[0057] 1) According to Pb 0.90 Sr 0.10 Zr 0.53 Ti 0.47 o 3 -0.008CaFe 0.95 Ga 0.05 o 5 / 2 +0.005MnO 2 General Formula for Accurately Weighing Pb in Stoichiometric Ratio 3 o 4 , SrCO 3 , ZrO 2 、TiO 2 , CaCO 3 , Fe 2 o 3 , Ga 2 o 3 , MnO 2 . Put all raw material powders into a ball mill jar, add deionized water, mix for 4-6 hours, pour out and dry;

[0058] 2) After sieving and briquetting the uniformly mixed powder, place it in a high-temperature furnace and synthesize it at 820°C for 2 hours to obtain the required phase;

[0059] 3) Break the synthesized powder into a ball mill tank, add deionized water, and pour it out for drying after 6 hours of ball milling;

[0060] 4) adding PVA to the ball-milled powder as a binder, granulating, pressing and molding under a pressure of 200 MPa, and keeping the pressed gree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com