Overall jacking construction method for large-area bolt-sphere net rack

A technology of overall jacking and construction methods, which is applied in the direction of construction and building construction, to achieve the effects of simple construction, reduced risk of high-altitude operations, and the elimination of rod damage and rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

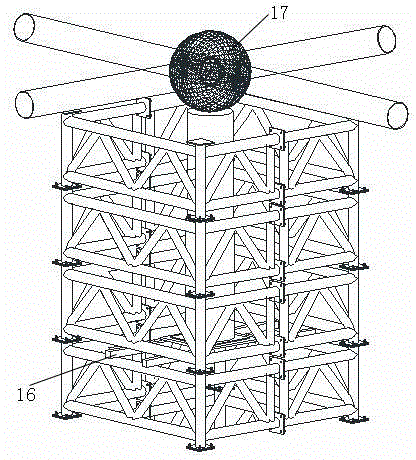

[0030] like figure 1 Shown: a large-area bolted ball grid overall jacking construction method, including the following steps:

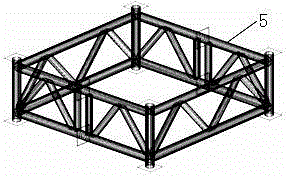

[0031] Step 1: Determine the plane position of the assembly, level the site, position and set out the line, and the plane position is the orthographic projection position of the bolt ball net frame on the horizontal plane;

[0032] Step 2: Assemble the bolt ball net frame on the ground, from the middle to both sides, and start to assemble from top to bottom;

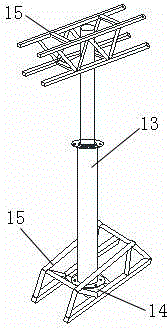

[0033] Step 3: Evenly arrange the short-distance lifting device of the large-scale network frame on the upper support point of the bolted ball network frame; Figure 4 As shown: the large grid short-distance lifting device includes a top plate 3, a support leg 1, a traction chain 4 and a suspension ring 2; the support legs are arranged on the bottom surface of the top plate, and there are at least three support legs arranged in a uniform circle; one end of the support leg It is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com