A high-precision miniature two-way regulating valve for military industry

A high-precision, regulating valve technology, applied in the field of regulating valves, can solve the problems of motor necrosis, affecting flight, unscientific valve design, etc., and achieve the effect of simple and scientific structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

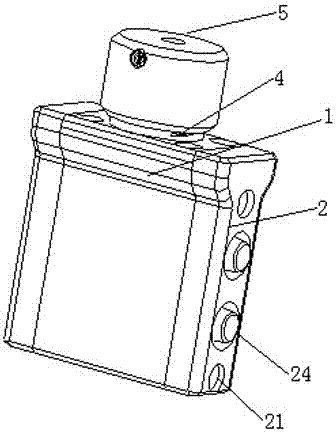

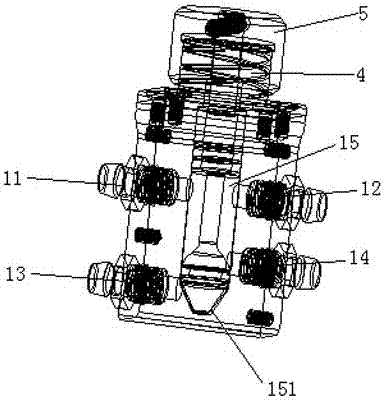

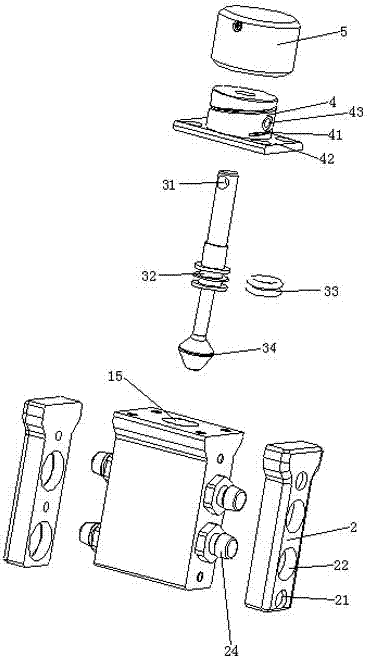

[0018] See Figure 1 to Figure 5 As shown: the present invention includes a body 1, a protective and fixed cover plate 2, a valve stem 3, a fixed cover 4, and a knob 5. It is characterized in that: the body 1 is provided with a valve cavity 15, and the bottom end of the valve cavity 15 is a conical surface structure 151 , the side of the body 1 is also provided with No. 1 water inlet 11, No. 1 water outlet 12, No. 2 water inlet 14, No. 2 water outlet 13, No. 1 water inlet 11, No. 1 water outlet 12. The No. 2 water inlet 14 and the No. 2 water outlet 13 are respectively provided with connection and fixed joints 24, the side of the body 1 is connected with a protective and fixed cover 2, and the protective and fixed cover 2 is provided with accommodating connection and fixed joints 24. The fixing hole 22, the valve stem 3 is installed in the valve chamber 15, the top of the valve stem 3 is provided with a conical head 34 that cooperates with the conical surface structure 151 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com