Indoor air freshness retaining machine provided with filter film component clamping and assembling mechanism and use method of indoor air freshness retaining machine

A technology of indoor air and filter membrane, which is applied in the field of indoor air preservation machines, can solve the problems of inconvenient installation and disassembly for cleaning, limited use places, and poor use effect, and achieve the effects of avoiding rigid contact, simple structure, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

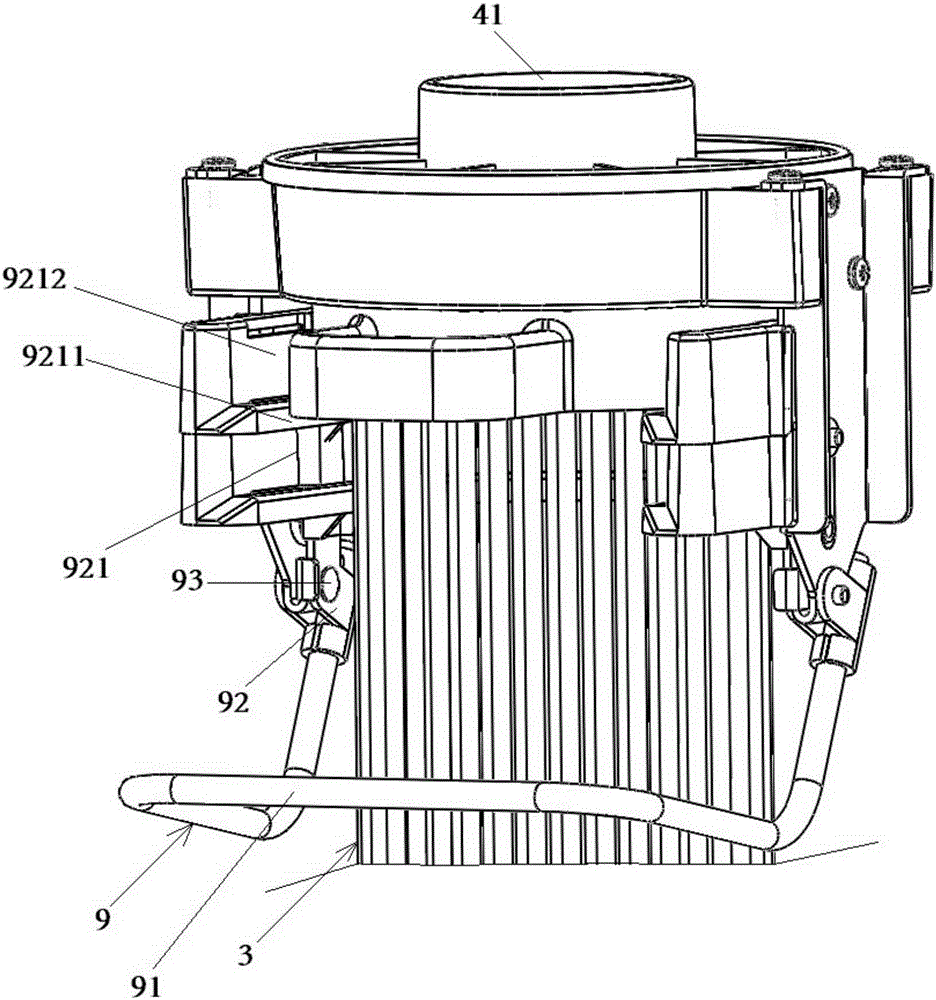

[0028] Corresponding reference characters indicate corresponding parts throughout the views of the drawings.

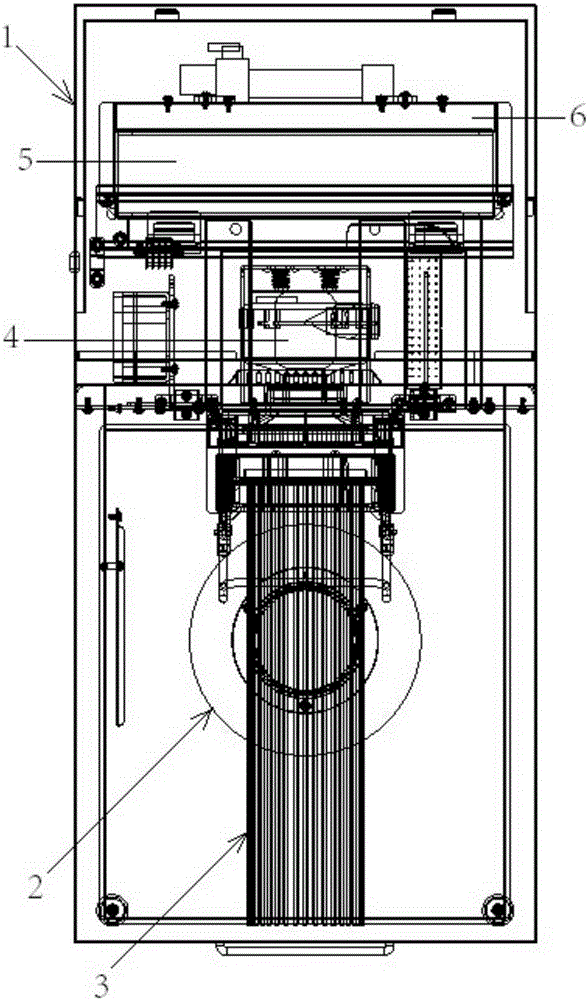

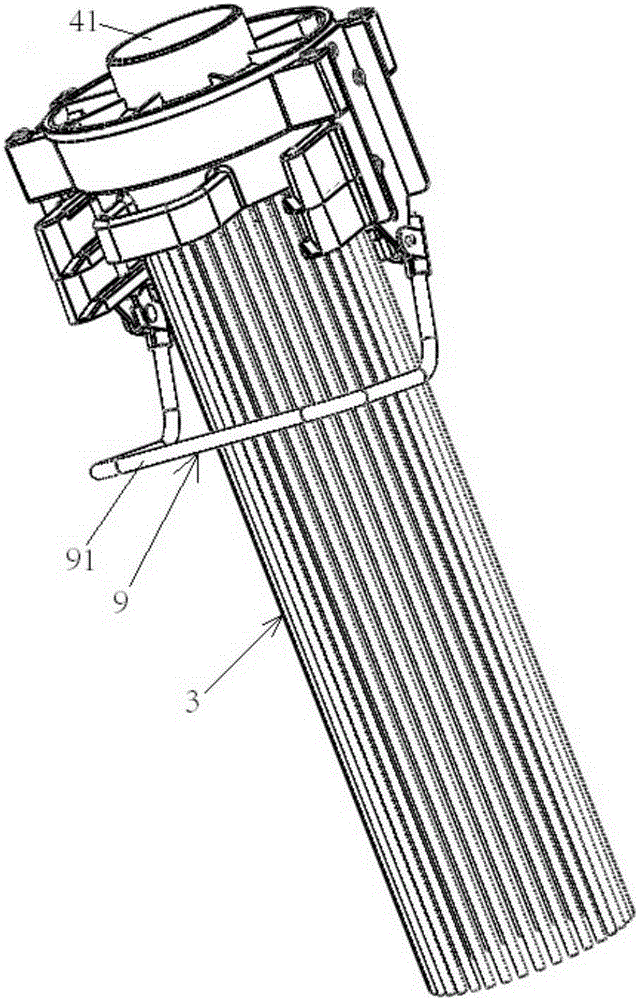

[0029] An indoor air fresh-keeping machine with a filter membrane assembly clamping mechanism and its use method, comprising an indoor air fresh-keeping machine 1, a filter membrane assembly 3 arranged on the indoor air fresh-keeping machine 1 and a filter membrane assembly clamping mechanism 9, the filter membrane The assembly 3 is set on the indoor air fresh-keeping machine 1 through the clamping mechanism 9 of the filter membrane assembly.

[0030] The indoor air fresh-keeping machine 1 is equipped with an outdoor air inlet pipe 2, a filter membrane module 3, a fan (and a controller) 4, a sound-absorbing chamber 10, a deodorizing high-efficiency filter chamber 5, a heating chamber 6, an air outlet 7, a display controller, and 24V Power supply (220VAC input, 24VDC output), etc. The outdoor air inlet pipe 2 is sequentially connected to the filter membrane module 3 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com