Coiled tube anti-frost-cracking system and method used for air conditioner with double heat sources

An air-conditioning coil, dual heat source technology, applied in air-conditioning systems, household heating, heating methods, etc., can solve the problems of wasting energy, freezing cracks of fan coils, etc., and achieve the effect of preventing coils from freezing and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

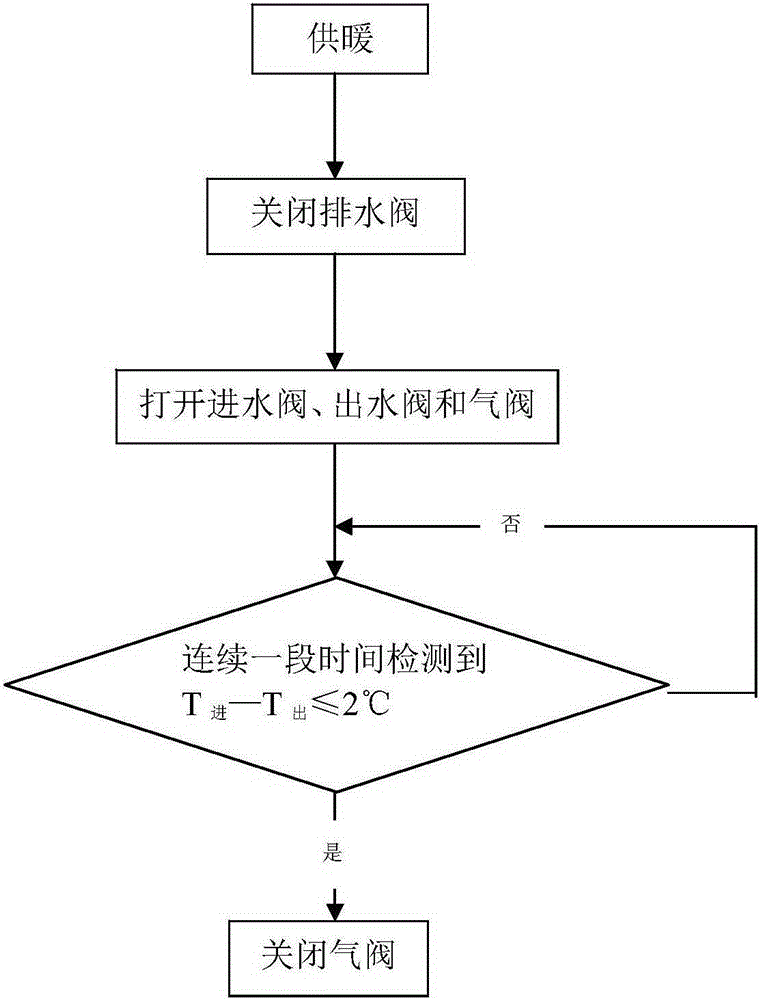

[0054] Such as figure 2 As shown, a coil anti-freeze cracking method for a dual heat source air conditioner, when the air conditioner is in heating mode, the controller performs the following steps:

[0055] Step 1: Close the drain valve, open the water inlet valve, water outlet valve and air valve;

[0056] Step 2: The water inlet temperature sensing device detects the water temperature T of the water inlet pipeline进 , the outlet water temperature sensing device detects the water temperature T of the water pipeline 出 ;

[0057] Step 3: Compare T 进 and T 出 ;

[0058] Step 4: When T 进 and T 出 When the difference between them is less than a predetermined threshold, preferably after a period of time, the gas valve is closed.

[0059] Preferably, the predetermined threshold is not greater than 2°C, specifically, may be 2°C.

Embodiment 2

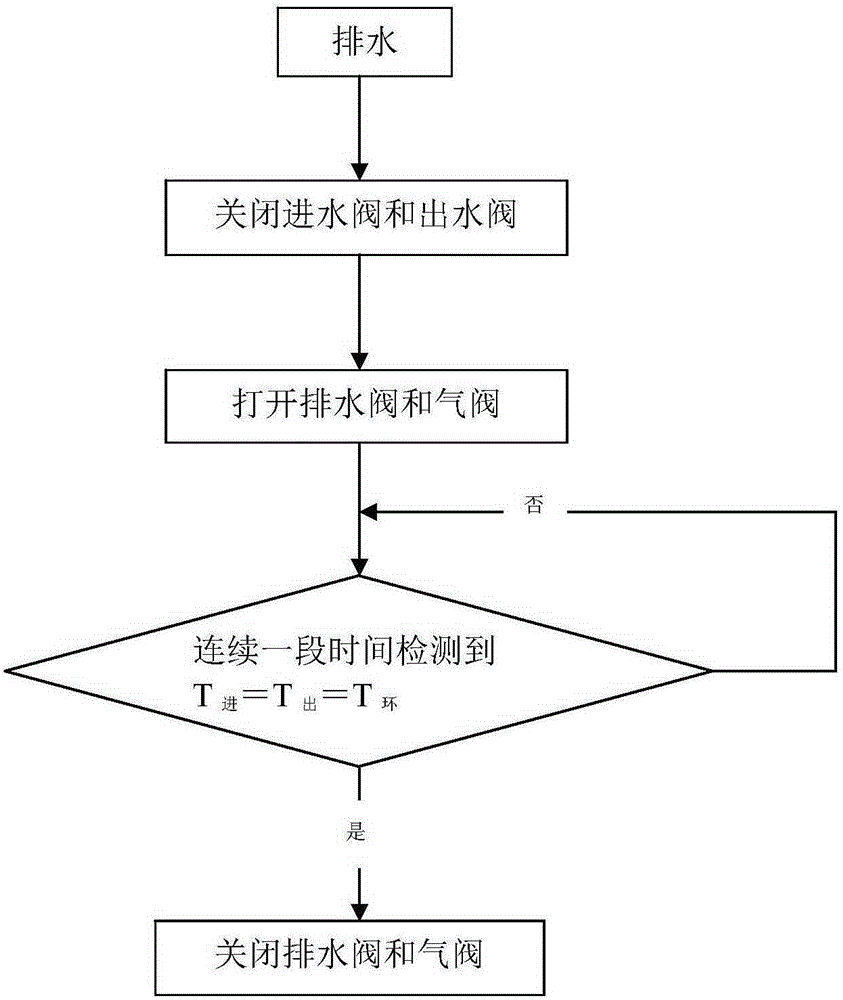

[0061] Such as image 3 As shown, a coil antifreeze cracking method for dual heat source air conditioners, when the controller receives a drainage signal, the controller performs the following steps:

[0062] Step 102: close the water inlet valve and the water outlet valve, open the drain valve and the air valve;

[0063] Step 103: The water inlet temperature sensing device detects the water temperature T of the water inlet pipeline 进 , the outlet water temperature sensing device detects the water temperature T of the water pipeline 出 ;

[0064] Step 104: Compare T 进 , T 出 and ambient temperature T 环 ;

[0065] Step 105: If T 进 =T 出 =T 环 , preferably after a period of time, it is determined that the water in the air conditioning coil has been drained, and the drain valve and the air valve are closed.

[0066] Preferably, the drainage signal is manually input by the user or automatically set and input by the coil antifreeze cracking system for dual heat source air con...

Embodiment 3

[0068] Such as Figure 4 As shown, a coil anti-freeze cracking method for a dual heat source air conditioner, when the internal unit of the air conditioner is shut down or the cooling mode is running, the controller performs the following steps:

[0069] Step 201: The water inlet temperature sensing device detects the water temperature T of the water inlet pipeline 进 , the outlet water temperature sensing device detects the water temperature T of the water pipeline 出 ;

[0070] Step 202: Compare T 进 and T 出 ;

[0071] Step 203: When T 进 ≤ and T 出 When ≤ the predetermined threshold, preferably after a period of time, a drain signal is sent to control the coil antifreeze cracking system used for dual heat source air conditioners to automatically drain the water in the coil.

[0072] Preferably, the predetermined threshold is not greater than 2°C, specifically, may be 2°C.

[0073] Further, when the controller sends a drain signal, the above-mentioned coil antifreeze crac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com