Test method and high temperature test device for locking torque test

A technology of locking torque and test method, which is applied in the direction of measuring torque/torsion force during tightening and using electric methods for temperature control, etc. It can solve the problems that the locking torque cannot be truly reflected and the reliability of the nut cannot be simulated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

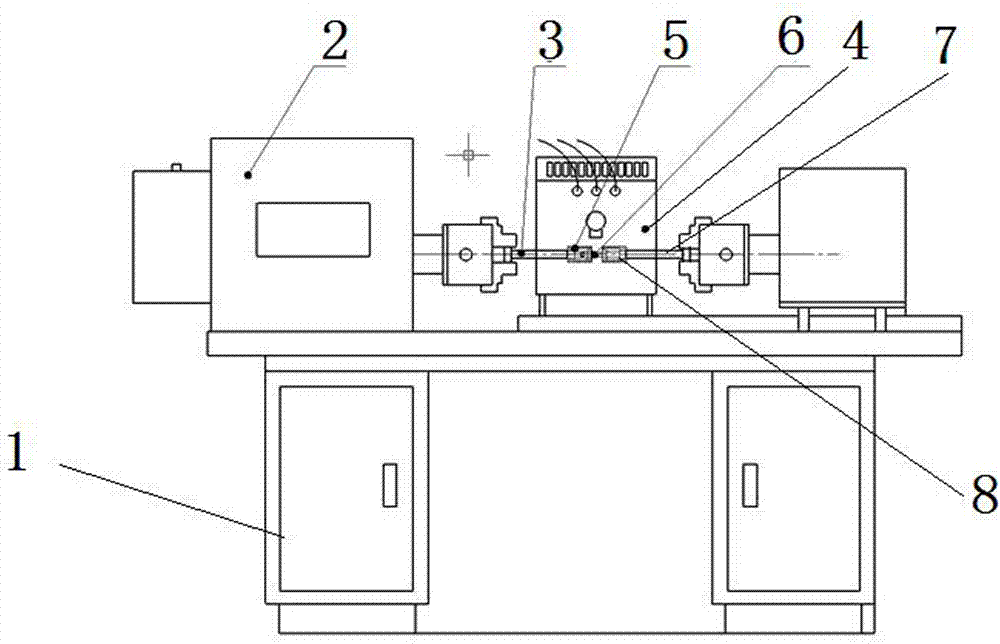

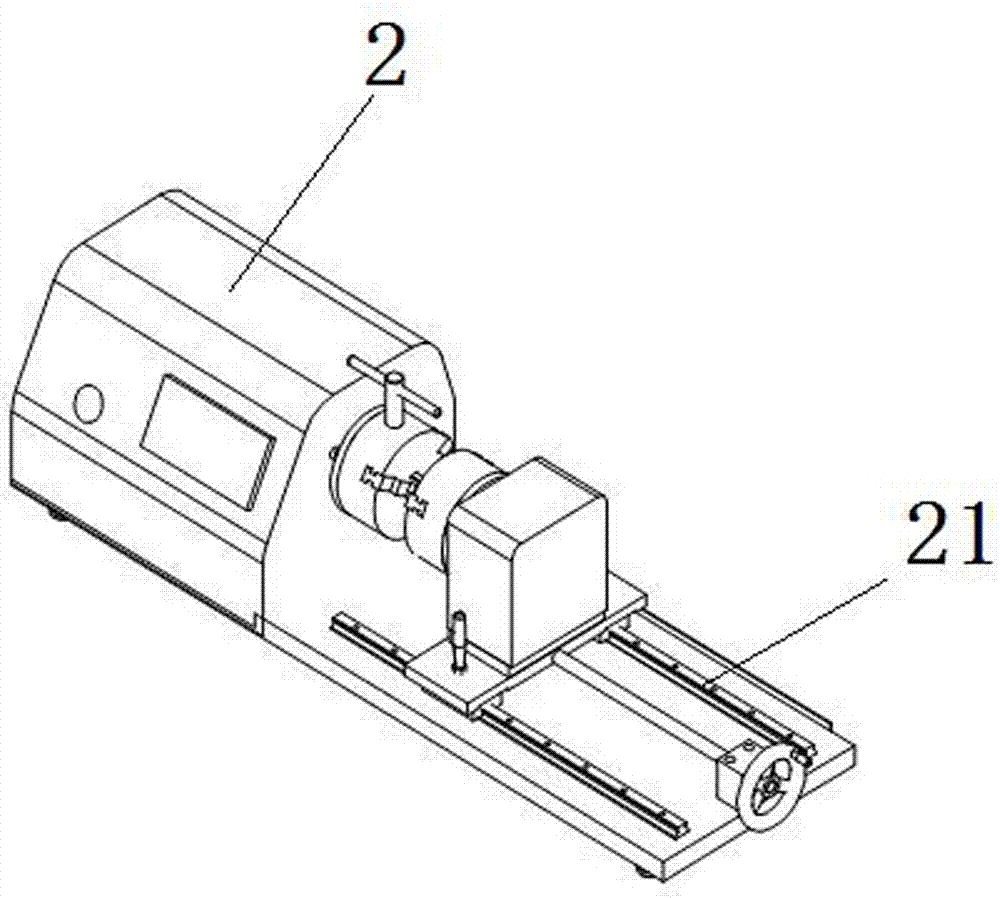

[0024] The embodiment of the test method of locking torque test of the present invention: as Figure 1-4 shown, including the following steps, (1), screw the nuts into the test bolts, and put the nuts and test bolts into the corresponding sleeves, click the "Start" button of the test device to start the test, the test device includes Force torque testing machine 2, at the moment when the bolt and the nut are unscrewed relative to each other, click the "Pause" button to record the maximum torque for the first screwing in, and click "Continue" to complete the first cycle; (2), then the self-locking The nuts are heated and baked in the high temperature furnace 4 for 6 hours at the standard specified temperature; (3) Cool the nuts to the indoor ambient temperature, lubricate the bolts and nuts with oil, set the cycle program for 15 times, and click the "Start" button first , turn half a circle when screwing in, put the bolts and nuts into the corresponding sleeves at the moment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com