Heat exchanger performance experiment device

A technology of experimental devices and heat exchangers, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of unable to truly simulate the compound changes of heat exchanger pressure and temperature, unable to meet the test requirements of special vehicle heat exchangers, and waste of resources and other problems, to save test time and cost, improve assessment intensity, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

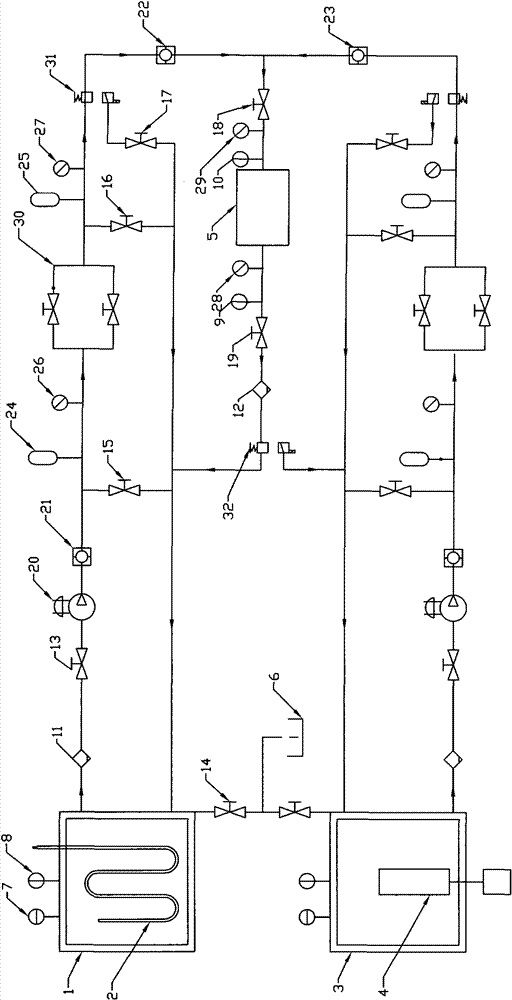

[0014] Such as figure 1 As shown, the experimental device of the present invention includes a control system, a hot oil tank and a thermal circulation pipeline, a cold oil tank and a cold circulation pipeline, and a test pipeline.

[0015] The test pipeline includes reversing valve B32, oil filter B12, gate valve / electric control valve G19, gate valve / electric control valve F18 and parallel check valve B22, check valve C23 connected in sequence, between gate valve / electric control valve G19 and The test piece 5 of the heat exchanger to be tested is installed between the gate valve / electric control valve F18, the temperature sensor B9 and the pressure sensor C28 are installed at the oil outlet of the test piece 5, and the temperature sensor C10 and the pressure sensor D29 are installed at the oil inlet end of the test piece 5.

[0016] A liquid level sensor 7 and a temperature sensor A8 are installed on the hot oil tank to monitor the medium oil, a heater 2 is installed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com