Large-screen naked-eye 3D all-in-one machine structure and preparation method thereof

A preparation process and an all-in-one technology, applied in optical components, optics, instruments, etc., can solve the problems of module stability, insufficient appearance, high requirements for module stability, etc., to achieve stability and great aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

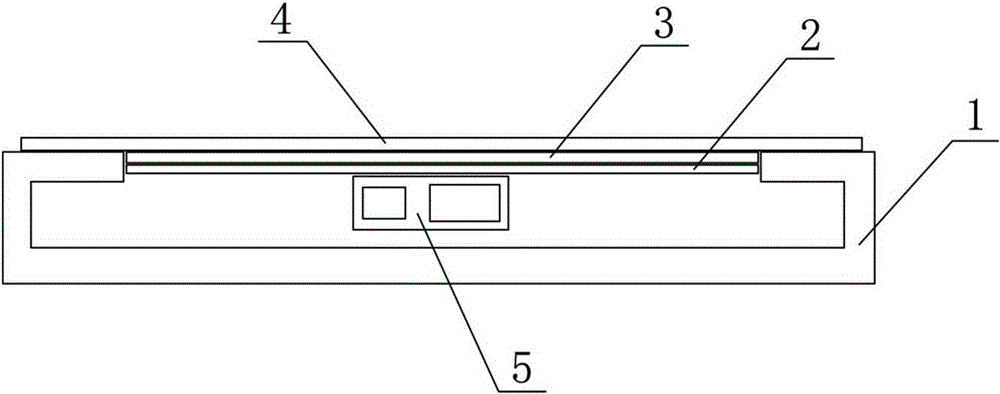

[0035] like figure 1 As shown, a large-screen naked-eye 3D all-in-one machine structure includes an outer frame 1, a grating 2, a curing glue 3, a glass substrate 4, and an integrated board 5. One side of the grating 2 is connected to the glass substrate 4 through a curing glue 3, and the glass The edge of the substrate 4 is attached to the outer frame 1; the outer frame 1 has a "U"-shaped groove as a whole, and the liquid crystal module and the integrated board 5 are installed in the groove of the outer frame 1, and the grating 2 faces the groove of the outer frame 1 side.

[0036] The overall size of the glass substrate 4 is larger than the overall size of the grating 2, the centerlines of the grating 2 and the glass substrate 4 coincide with each other, and the grating 2 and the glass substrate 4 are bonded in a non-full bonding manner.

[0037] A method for preparing a large-screen naked-eye 3D all-in-one machine structure, the steps of which are as follows:

[0038] Ste...

Embodiment 1

[0057] Taking the 82-inch 4K naked-eye 3D all-in-one machine as an example, the structural design and assembly of the large-screen naked-eye 3D all-in-one machine in this example is completed by the following steps:

[0058] Step A: Cutting the glass substrate. According to the size of the large-screen naked-eye 3D all-in-one machine structure liquid crystal panel and the size of the outer edge of the frame, determine the cutting size of the glass substrate 4. After cutting, it is necessary to grind the edges around and guide the safety corners to avoid scratches;

[0059] Step B: grating bonding, grating bonding is mainly divided into the following parts:

[0060] b1. cropping area, confirm the size of the grating 2 clipping according to the display area size of the glass substrate 4;

[0061] b2. Cutting inclination angle, according to the parameters of the design drawings such as the pixel structure of the large-screen naked-eye 3D all-in-one LCD panel and the setting of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com