A rotor structure of a permanent magnet motor with v-shaped oblique poles

A technology of permanent magnet motor and rotor structure, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of difficult realization of permanent magnet rotor, achieve the elimination of additional pulsating axial force, convenient operation, The effect of improving reliability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

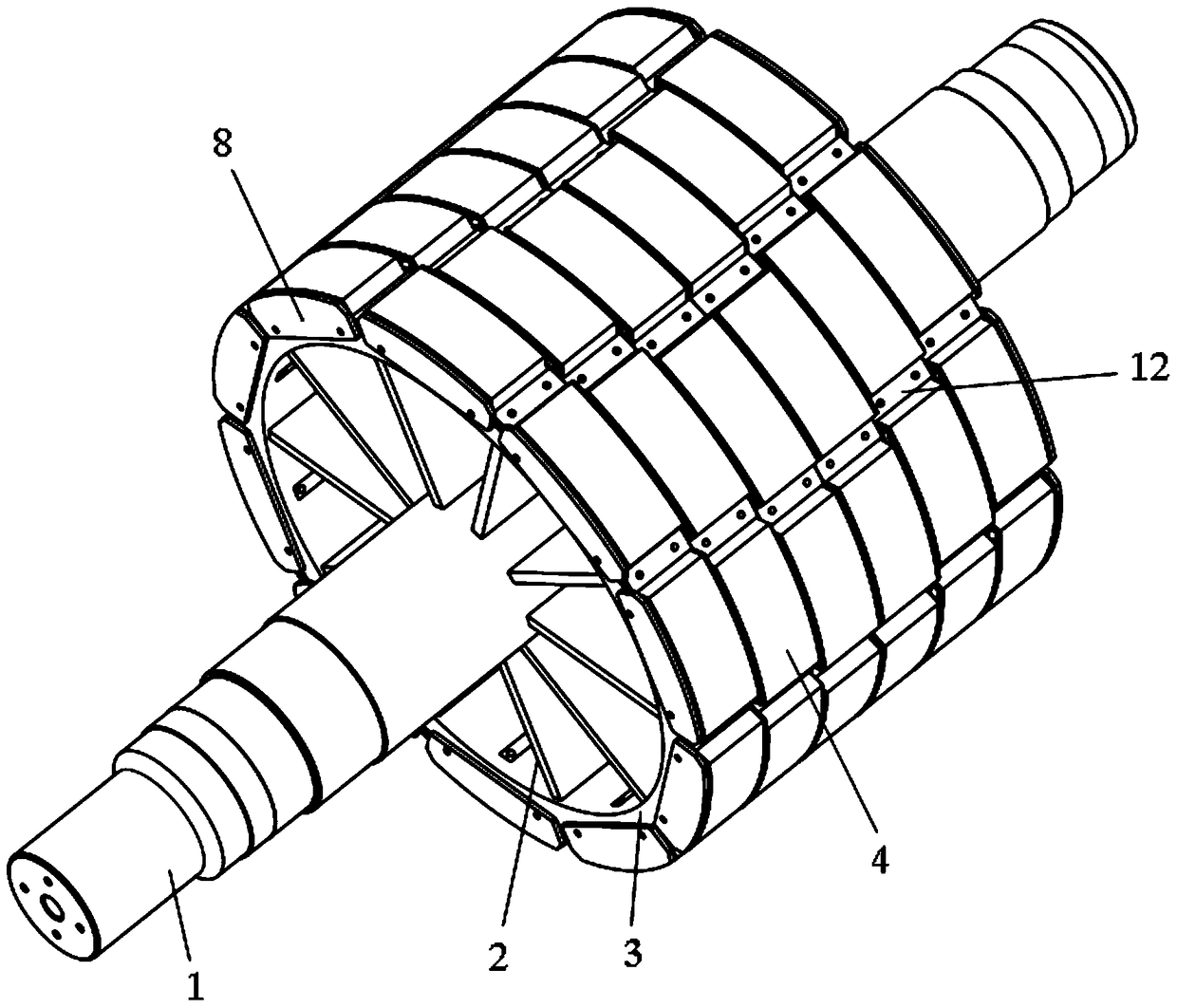

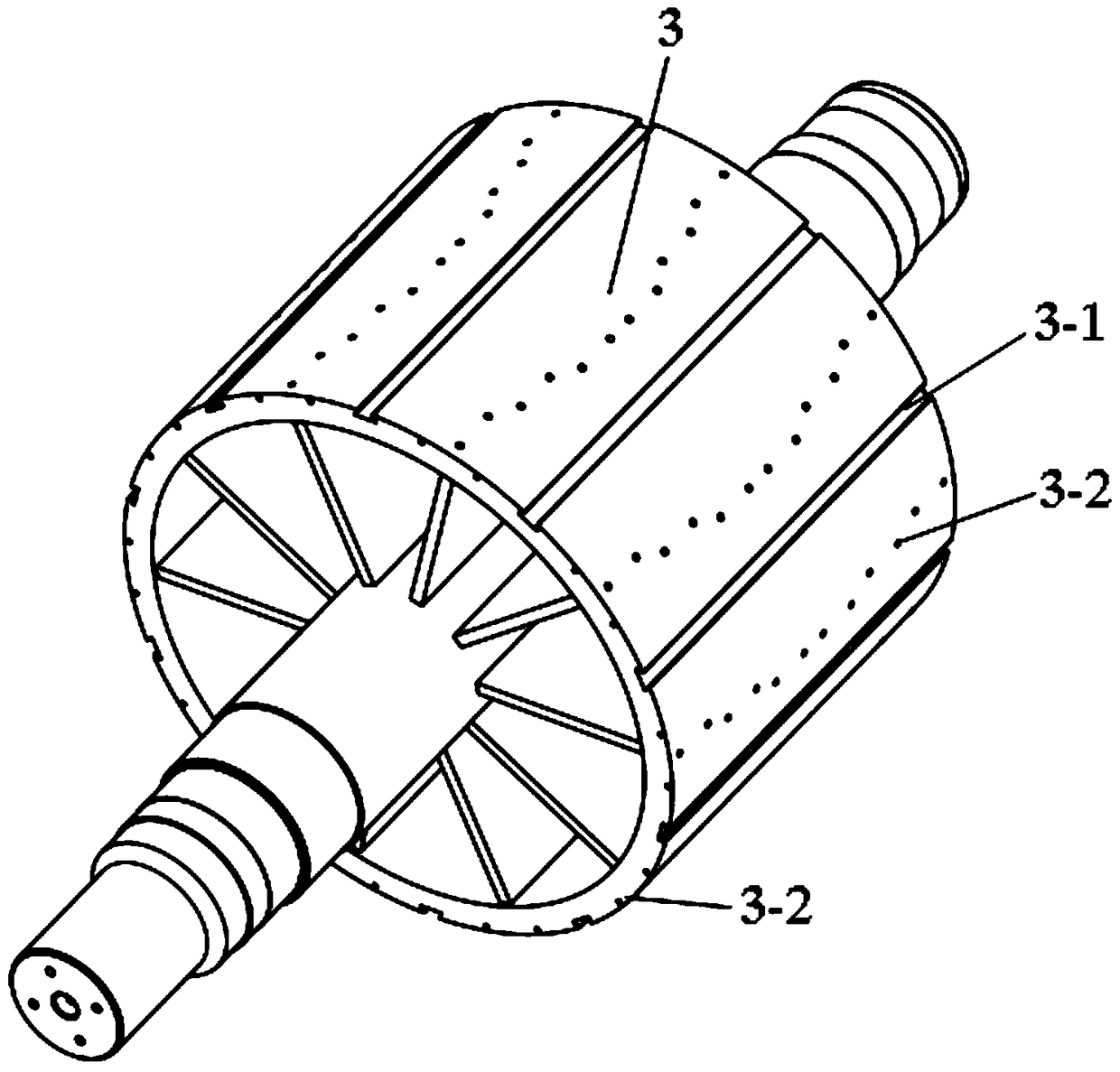

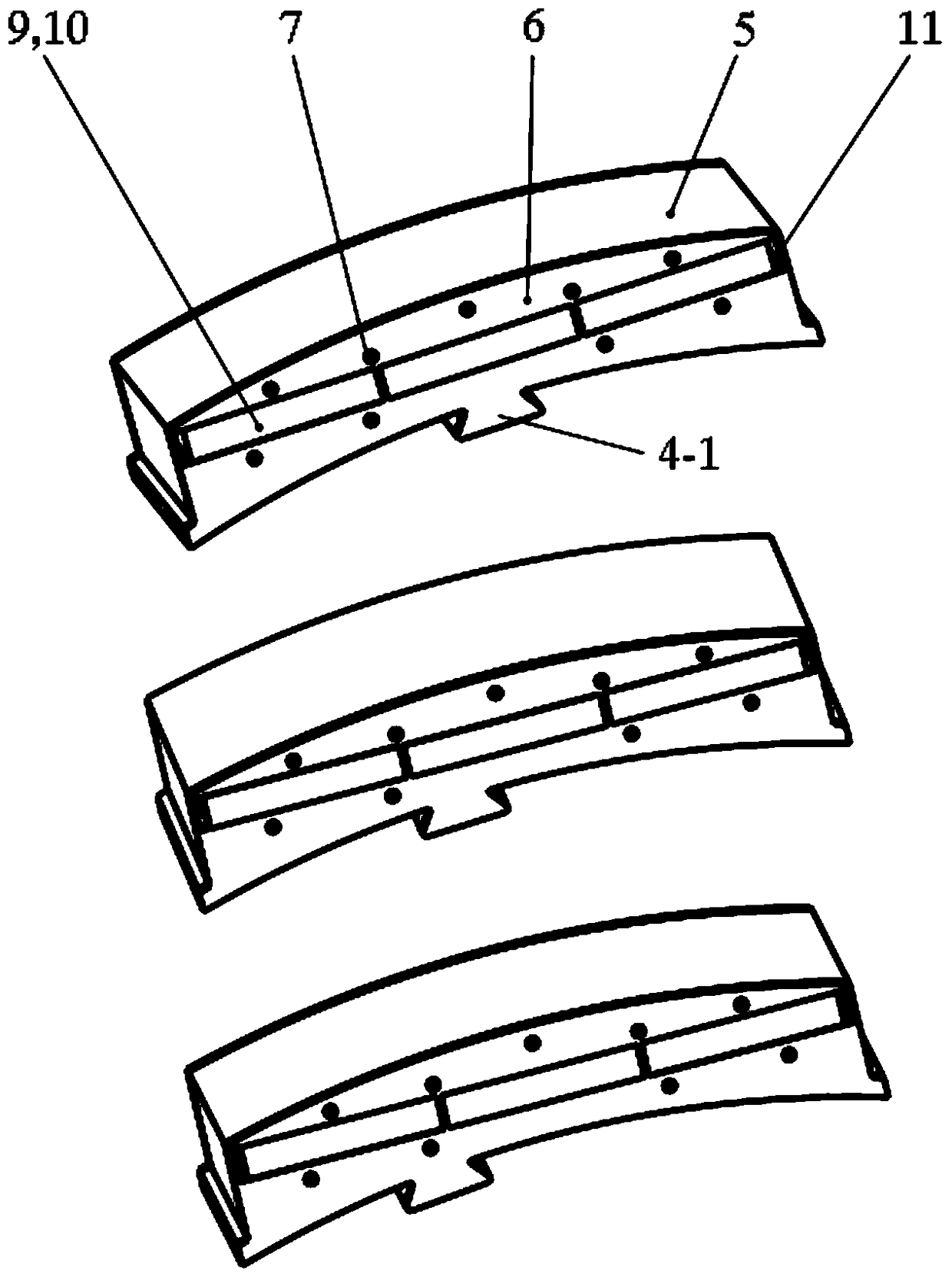

[0024] Such as figure 1 As shown, the rotor structure of the V-shaped oblique pole of the permanent magnet motor of the present invention mainly includes four parts: the rotating shaft 1, the web plate 2, the cylinder body 3 and the unit magnetic pole 4. Such as figure 2 As shown, the inner layer of the rotor is a cylinder structure, and the cylinder 3 and the shaft 1 are welded through the web 2; the outer surface of the cylinder 3 is circular, and the coaxiality between the cylinder 3 and the shaft 1 must be ensured during processing At the same time, a dovetail groove 3-1 and a threaded hole 3-2 are machined in the axial direction on the surface of the cylinder 3, which are used to fix the unit magnetic pole 4 and the unit magnetic pole bead 12, and a threaded hole 3-2 is also processed on the end surface of the cylinder 3 , used to fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com