Self-propelled crawler rotary tillage and trench digging all-in-one machine

An all-in-one, self-propelled technology, applied in the field of rotary tillers, can solve the problems of decreased work efficiency, and the farming effect cannot be guaranteed to meet agronomic requirements, so as to save costs, improve heat dissipation, and facilitate installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

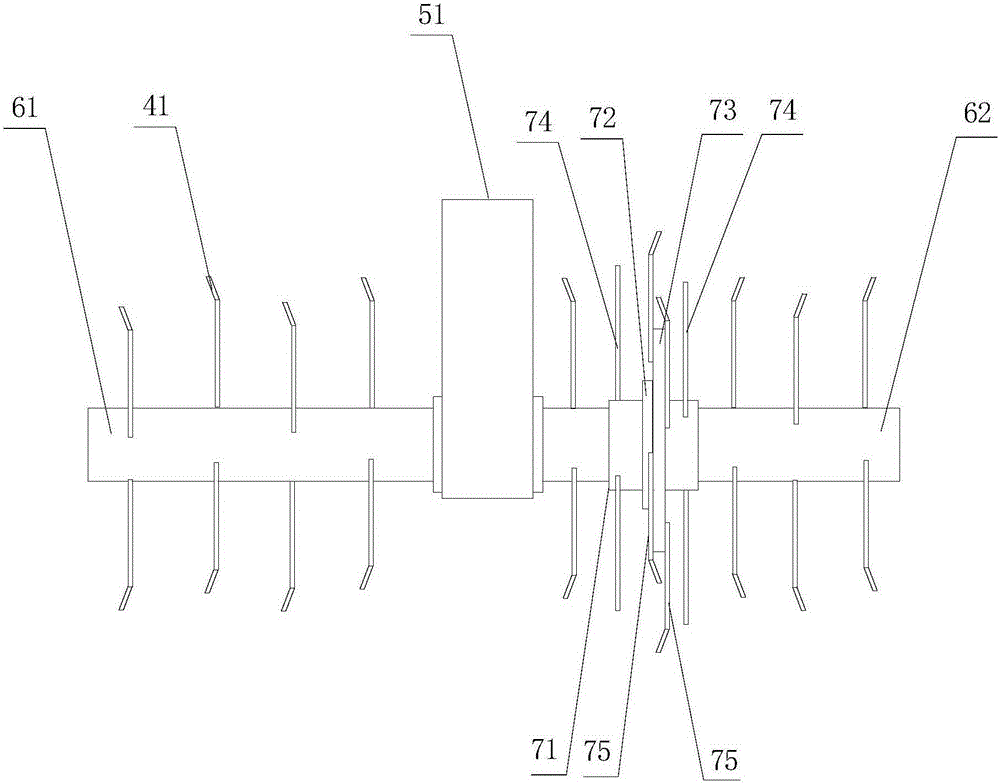

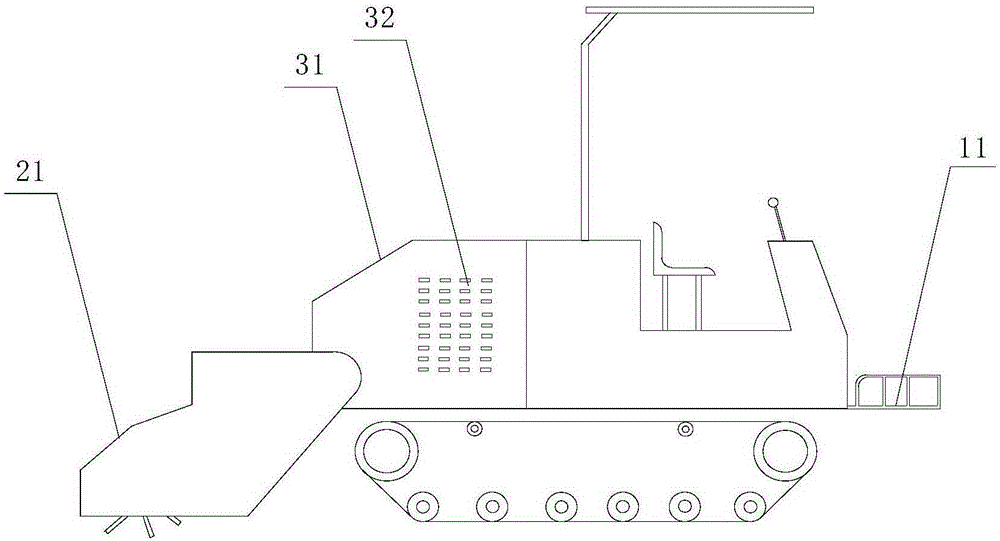

[0043] figure 1 , 2 Schematically provides a simplified structural diagram of a crawler self-propelled rotary tiller and ditching integrated machine according to an embodiment of the present invention, as shown in figure 1 , 2 As shown, the all-in-one machine includes:

[0044] Power plant, crawler belt and vehicle frame etc., these parts all are the prior art of this field, do not repeat them here;

[0045] Transmission gearbox 51, the transmission gearbox is arranged at the tail of the all-in-one machine, and is connected to the power device through a belt or chain;

[0046] A rotating shaft, such as a cylindrical structure, passes through the transmission gearbox and is driven, and the rotating shaft is divided into a left part 61 and a right part 62 by the transmission gearbox; Both ends of the shaft are rotatably fixed on the bracket;

[0047] The first group of blades, the first group of blades are fixed on the rotating shaft through the knife seat; the ends of the ...

Embodiment 2

[0063] An application example of the crawler self-propelled rotary tiller and ditching integrated machine according to Embodiment 1 of the present invention.

[0064] In this application example, one end of the opener is fixed on the rotating shaft on the bracket, and has an arc-shaped bending part; the adjustment part is specifically: a nut is fixed on the bending part, and a bolt matching the nut passes through One end of the nut bears against the bracket, and the up and down position of the opener relative to the bracket is adjusted by rotating the bolt forward or reverse; the thickness of the third group of blades decreases from the root to the end, thereby A ditch with an isosceles trapezoidal cross-section is opened in the field; the ditching device is installed on the rotating shaft of the right part, and the distance between the ditching device and the right end of the bracket is equal to the distance between the ditch adjacent to the field ridge and the field ridge, so...

Embodiment 3

[0066] An application example of the crawler self-propelled rotary tiller and ditching integrated machine according to Embodiment 1 of the present invention.

[0067] In this application example, one end of the opener is fixed on the rotating shaft on the bracket, and has an arc-shaped bending part; the adjustment part is specifically: a nut is fixed on the bending part, and a bolt matching the nut passes through One end of the nut bears against the bracket, and the up and down position of the opener relative to the bracket is adjusted by rotating the bolt forward or reverse; the thickness of the third group of blades decreases from the root to the end, thereby A ditch with an isosceles trapezoidal cross-section is opened in the field; the ditching device is installed on the rotating shaft of the left part, and the distance between the ditching device and the left end of the support is equal to the distance between the ditch adjacent to the field ridge and the field ridge, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com