Jigsaw

A wire saw machine and technology of wire saw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

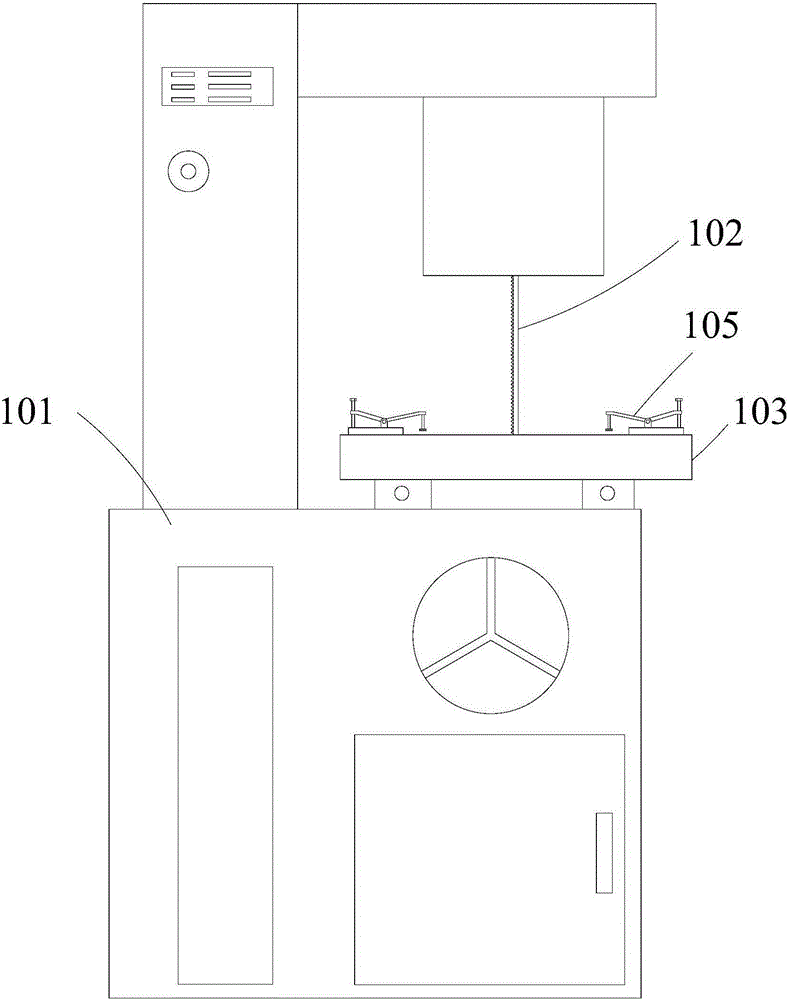

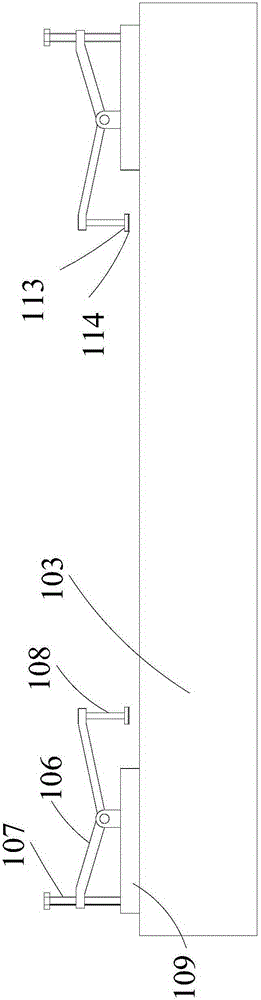

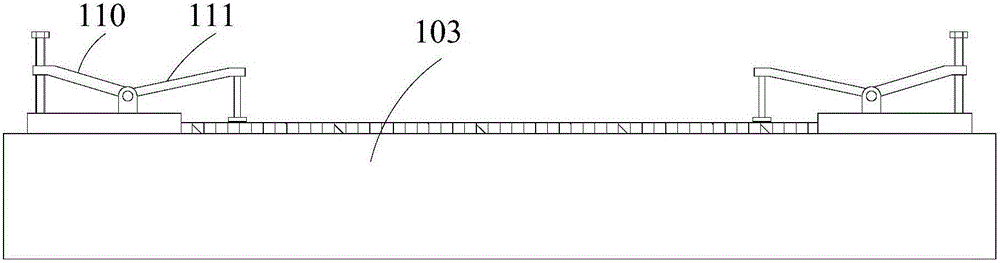

[0068] A wire saw machine, comprising a body 101, the body 101 includes a wire saw mechanism and a mounting table 103; the wire saw mechanism includes a saw blade 102; Giving groove 104, saw blade 102 passes through this feeding groove 104; Mounting table 103 is connected with body 101 flexibly, and mounting table 103 can move back and forth on body 101, and the top of mounting table 103 is working surface, and the left and right sides of this working surface Each set of press-fitting mechanisms is provided, and each set of press-fitting mechanisms includes five press-fit assemblies 105 arranged at intervals on the same straight line; the press-fit assemblies 105 include a connecting rod 106, and one end of the connecting rod 106 is screwed with a screw rod 107, The other end is connected with a depression bar 108, and the middle part of the connecting rod 106 is hinged with the installation platform 103; the screw rod 107 is vertically arranged with the installation platform 1...

Embodiment 2

[0070] A wire saw machine, comprising a body 101, the body 101 includes a wire saw mechanism and a mounting table 103; the wire saw mechanism includes a saw blade 102; Giving groove 104, saw blade 102 passes through this feeding groove 104; Mounting table 103 is connected with body 101 flexibly, and mounting table 103 can move back and forth on body 101, and the top of mounting table 103 is working surface, and the left and right sides of this working surface Each set of press-fitting mechanisms is provided, and each set of press-fitting mechanisms includes five press-fit assemblies 105 arranged at intervals on the same straight line; the press-fit assemblies 105 include a connecting rod 106, and one end of the connecting rod 106 is screwed with a screw rod 107, The other end is connected with a depression bar 108, and the middle part of the connecting rod 106 is hinged with the installation platform 103; the screw rod 107 is vertically arranged with the installation platform 1...

Embodiment 3

[0074] A wire saw machine, comprising a body 101, the body 101 includes a wire saw mechanism and a mounting table 103; the wire saw mechanism includes a saw blade 102; Giving groove 104, saw blade 102 passes through this feeding groove 104; Installing platform 103 is connected with body 101 flexibly, and installing platform 103 can move back and forth on the machine body 101, and the top of installing platform 103 is working surface, and the left and right sides of this working surface A group of press-fitting mechanisms are provided, and each set of press-fitting mechanisms includes five press-fit assemblies 105 arranged at intervals on the same straight line; the press-fit assemblies 105 include a connecting rod 106, and one end of the connecting rod 106 is screwed with a screw rod 107, The other end is connected with a depression bar 108, and the middle part of the connecting rod 106 is hinged with the installation platform 103; the screw rod 107 is vertically arranged with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com