Device for cutting off soft pipeline

A technology for cutting devices and pipelines, which is applied in metal processing, etc., can solve the problems of high labor intensity, low production efficiency, easy to paralyze attention, etc., achieve a simple and compact structure, save workshop land costs, and facilitate high integration of equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

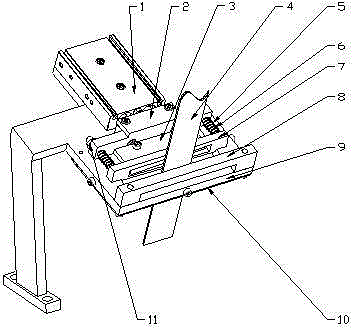

[0039] In order to describe in detail the technical content, structural features, objectives and effects of a flexible pipeline cutting device of the present invention, the following will be further described in conjunction with the accompanying drawings of examples.

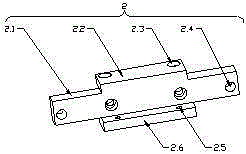

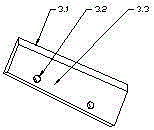

[0040] Such as Figure 1 to Figure 7 As shown, an example of a flexible pipeline cutting device is disclosed, including a cylinder 1, a traction seat 2, a blade 3, a cut pipeline product 4, a guide rod 5, a spring 6, an active chuck 7, a stationary chuck 8, and a support frame 9. Guard plate 10, nut 11, shield 12, cylinder 1 is fixed on the support frame 9 by bolt A, traction seat 2 is connected with the push plate of cylinder 1 by bolt B, active chuck 7 and guide rod 5 are welded Fixed, the spring 6 is set on the outer surface of the guide rod 5, the guide rod 5 is connected and limited by the nut 11 and the traction seat 2 slidingly, the blade 3 is fixed on the traction seat 2 by the bolt C, and the static chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com