Rail clamp

A rail clamping device and rail clamping technology, which is applied in the direction of brakes, railway car body parts, railway braking systems, etc. where the brake elements interact with the track, and can solve problems such as poor stability, upward tilting of the tractor, and jamming , to achieve the effect of preventing upturning, ensuring smoothness and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

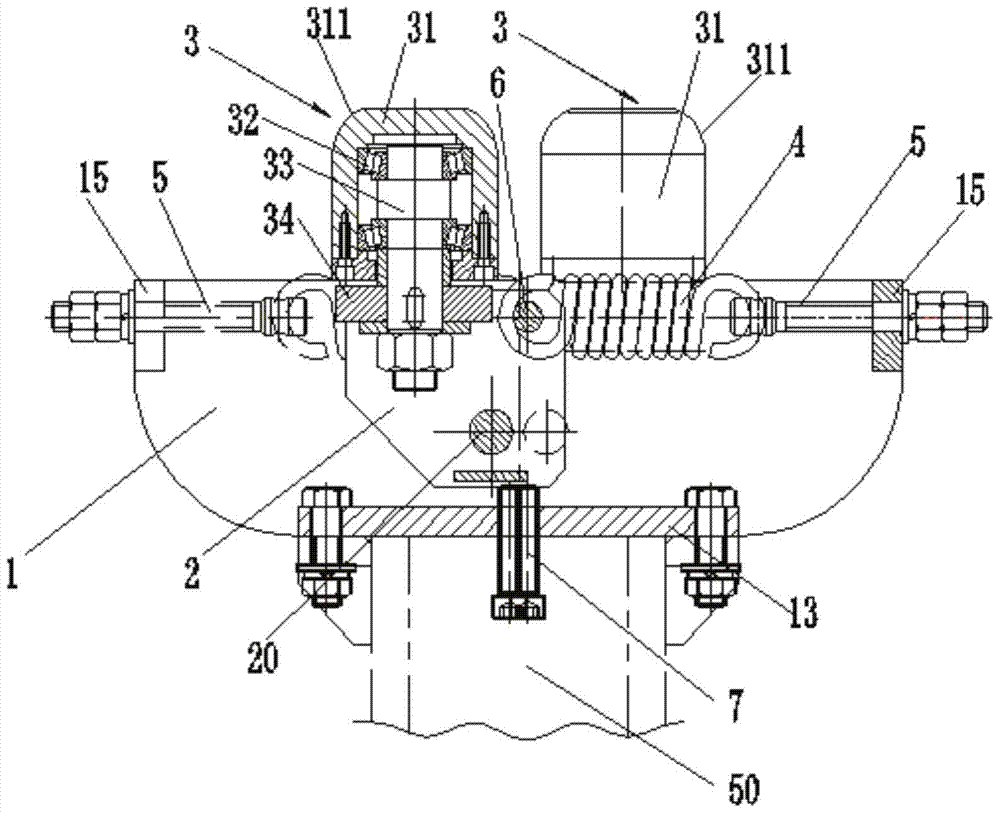

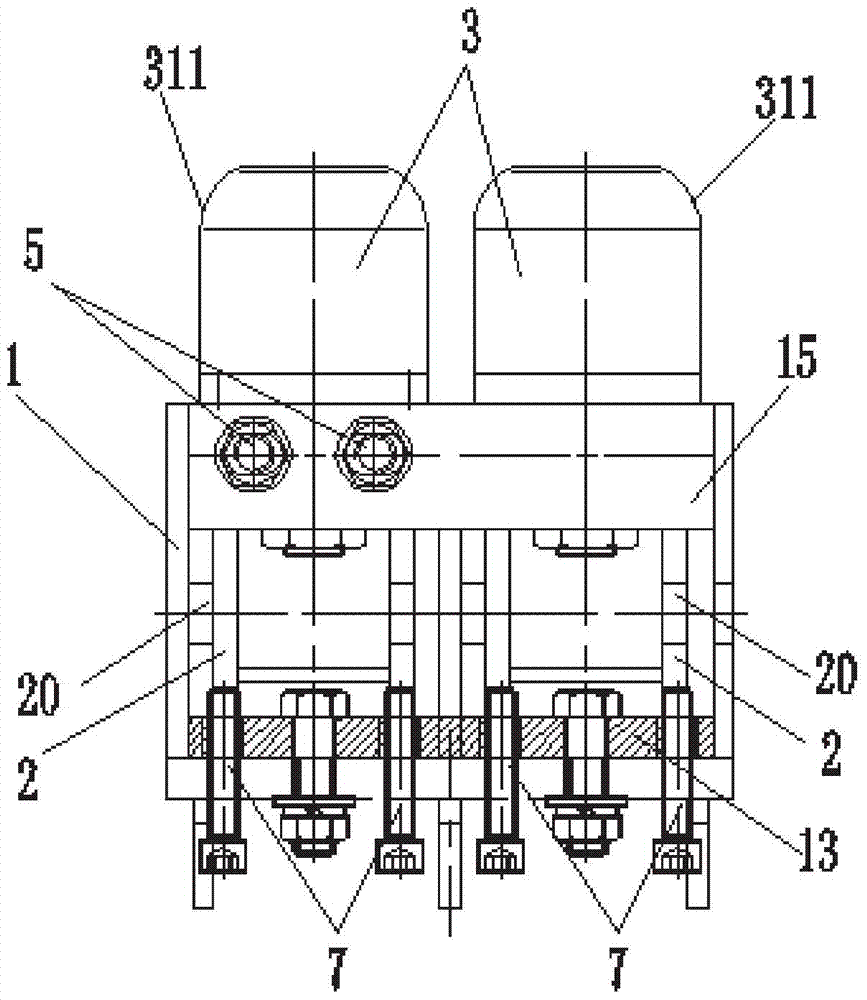

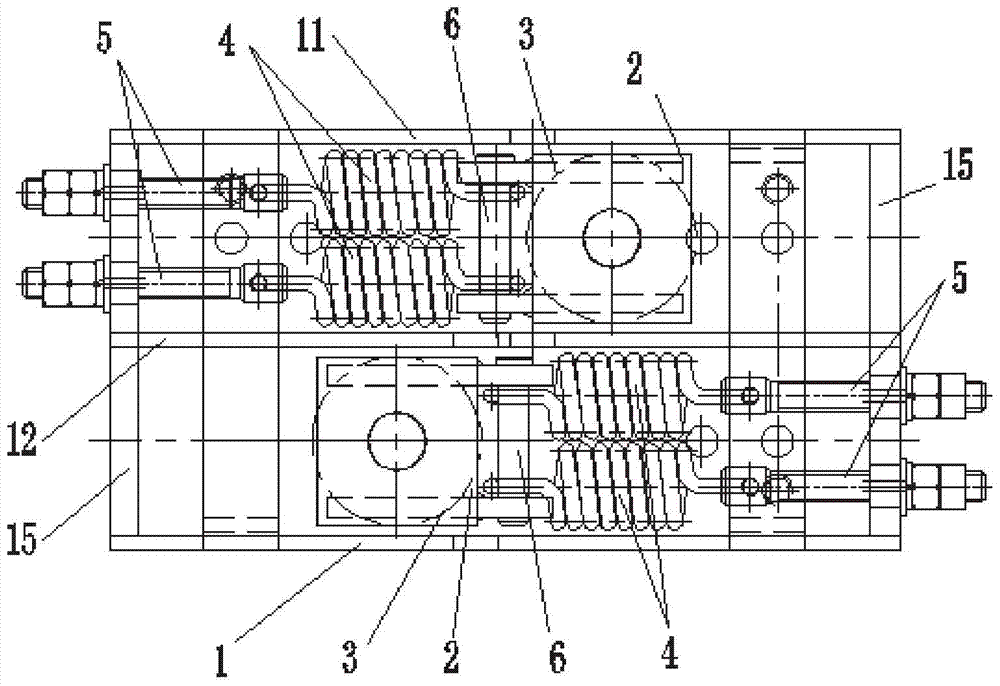

[0014] see figure 1 , 2 As shown in , 3, a rail clamping device includes a mounting frame 1, a rail wheel swing frame 2, a rail wheel assembly 3, a tension spring 4, a pull rod 5, a spring connecting rod 6 and a top tightening screw 7, the Both the rail wheel swing frame 2 and the rail wheel assembly 3 have two, the two rail wheel swing frames 2 are hinged with the mounting frame 1, and the two rail wheel assemblies 3 are connected to the corresponding rail wheel swing frame 2, And mutually misplaced arrangement, the two ends of described mounting frame 1 all have connecting plate 15, pull bar 5 is threadedly connected with corresponding connecting plate 15, and spring connecting rod 6 has two, is fixedly connected with corresponding rail wheel swing frame 2 respectively , there are at least two tension springs 4, and one end of the tensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com