Information detection bionic spiral robot in grain bin

A screw robot and screw propeller technology, applied in the field of grain condition detection in granary, can solve the problems of reduced operation efficiency, prone to failure, large cable coverage, etc., and achieve the effect of solving difficult wiring and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

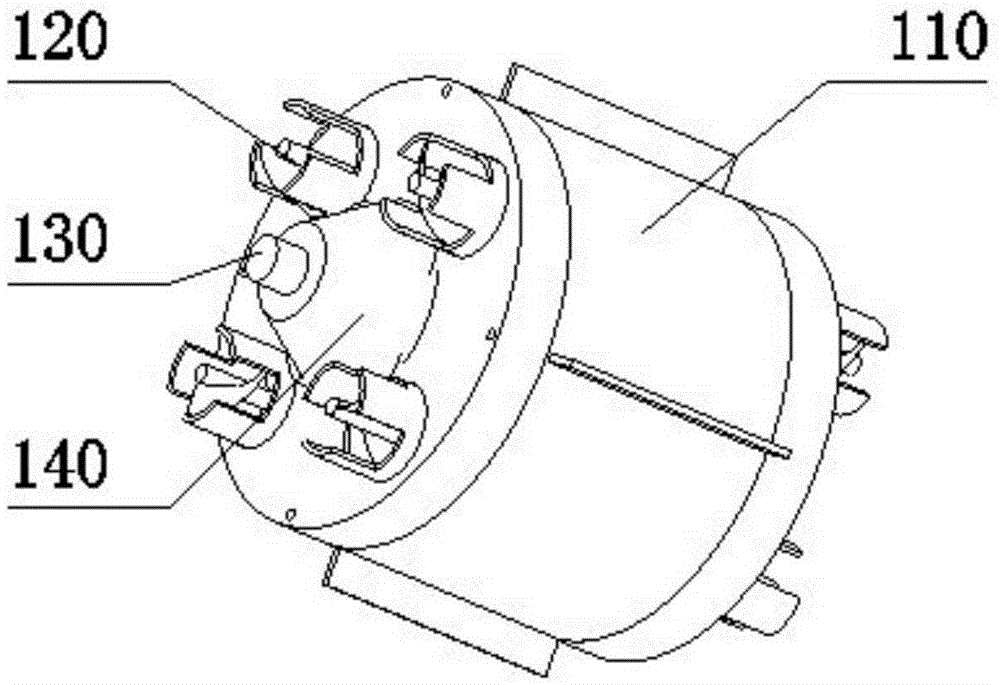

[0039] Such as figure 1 As shown, the present invention provides a bionic screw robot for information detection in a granary, including a housing 110 , a screw propeller 120 , and a sensor group 130 .

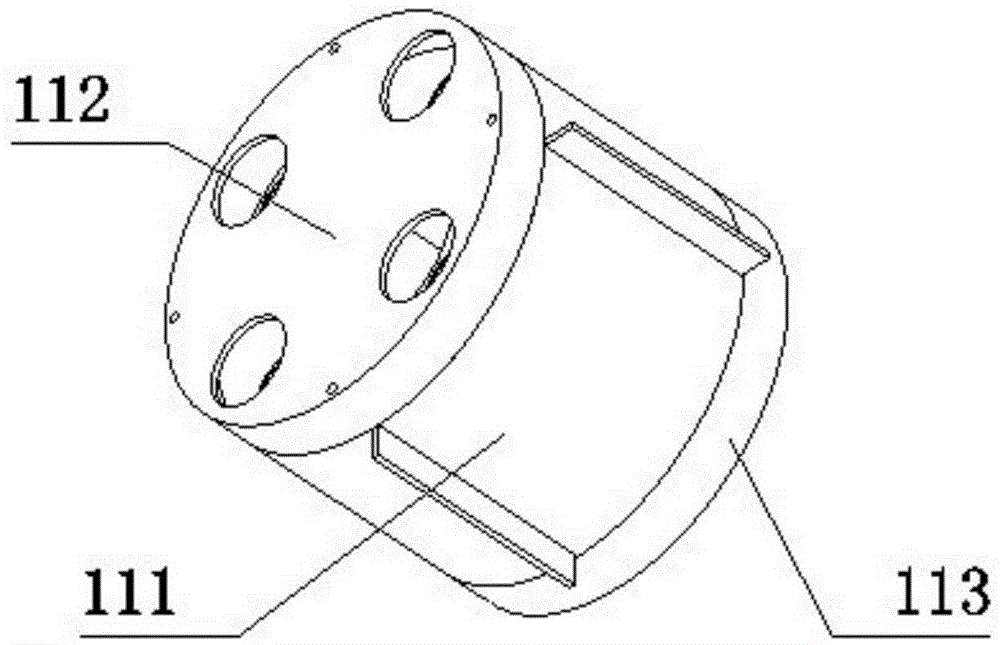

[0040] Such as figure 2 As shown, the housing 110 is cylindrical and consists of a side wall 111 , a front cover 112 and a rear cover 113 . The side wall 111 is a hollow cylinder with two ends open, and the front cover 112 and the rear cover 113 are respectively arranged at the front and rear openings of the side wall 111 , so that the inside of the housing 110 forms a relatively airtight space.

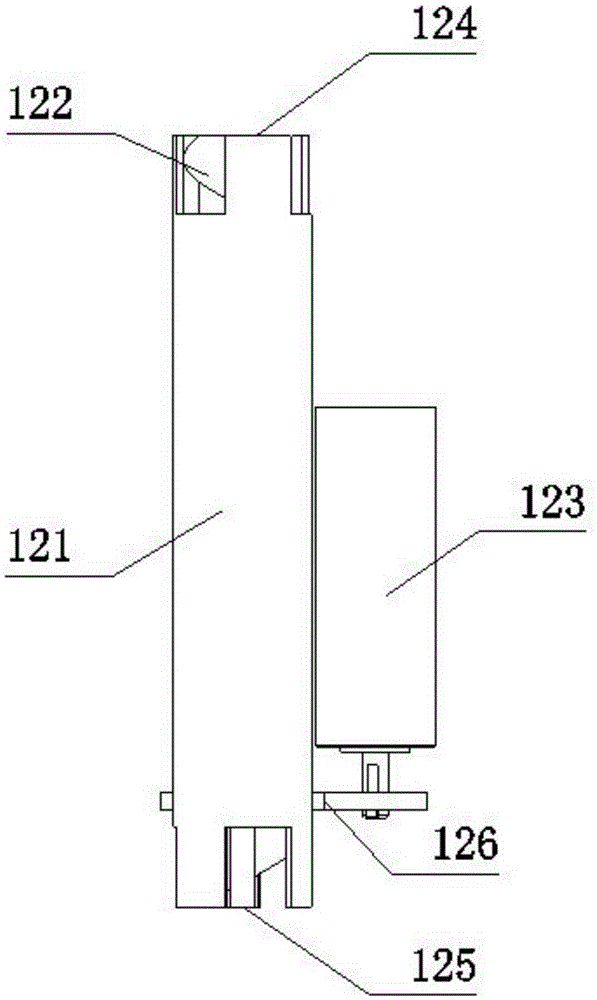

[0041] Such as image 3 As shown, the screw propeller 120 includes a transmission shaft 121 , a screw body 122 , and a driving motor 123 . The transmission shaft 121 is set in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com