Stepless-adjustment ball-hinge type multi-support-leg forward transverse shifting track system of bridge girder erection machine

A technology of traversing the track and stepless adjustment, which is applied in the erection/assembly of bridges, bridges, bridge construction, etc. It can solve the problems of pier damage, low degree of mechanized operation, and insufficient safety, and achieve strong vertical bearing capacity and Effects of stiffness, good transmission of vertical loads, strong stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

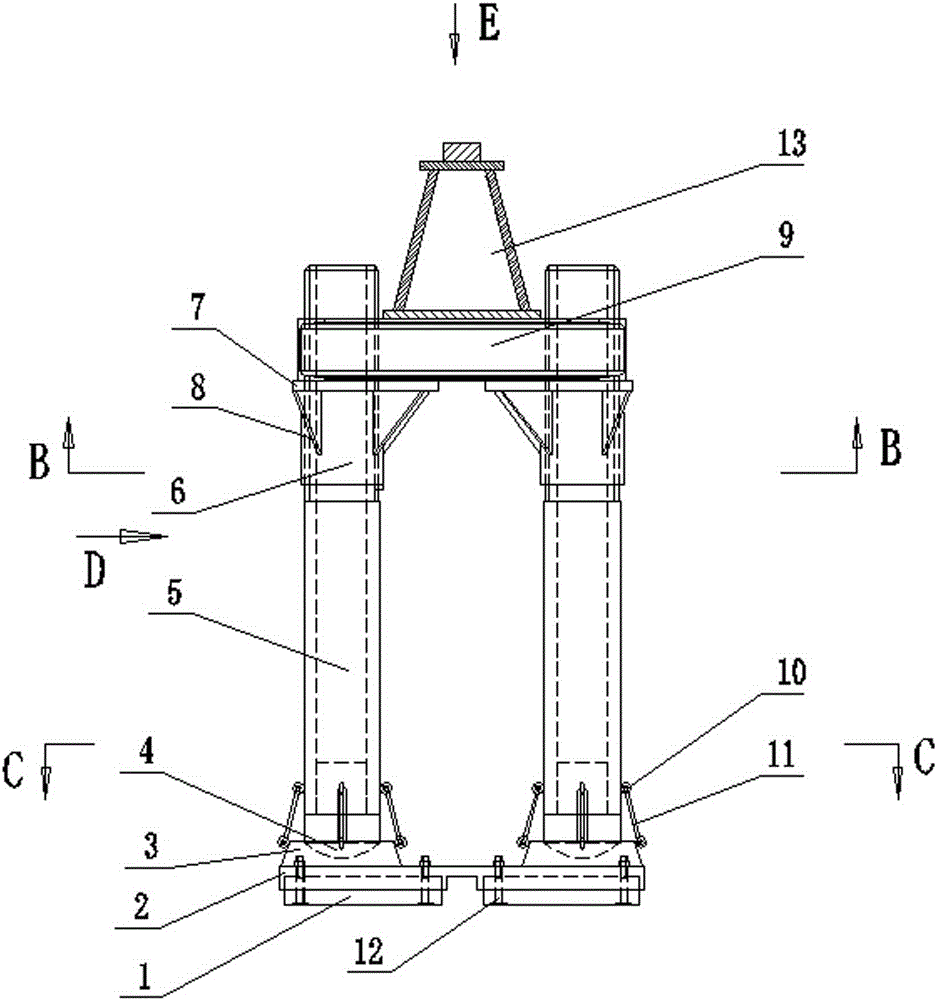

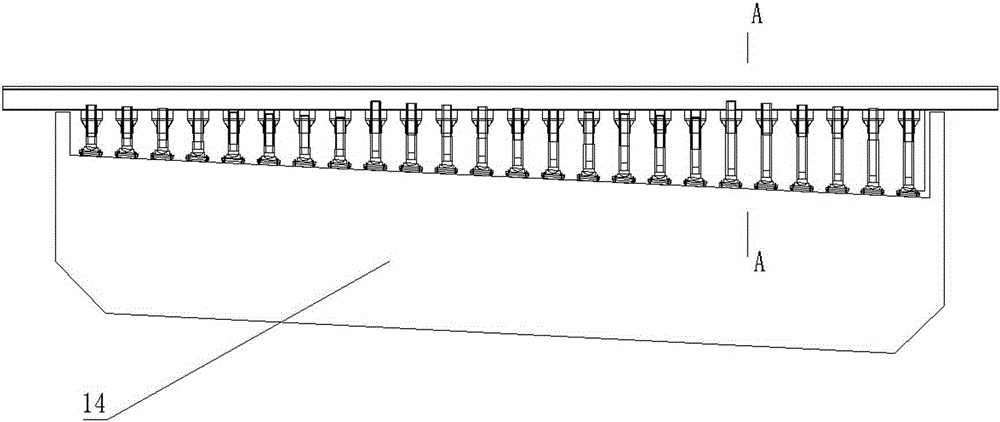

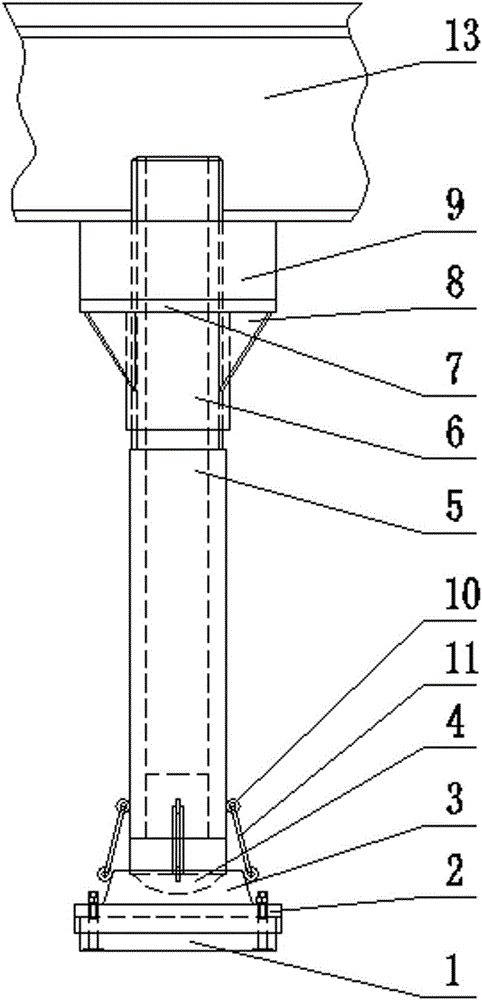

[0045] see figure 1 , 2, 3, 4, 5, 6, and 7, a stepless adjustment ball joint type multi-leg bridge erecting machine front traversing track system of the present invention, including the bridge erecting machine front traversing track 13, is characterized in that : the lower end surface of the front traversing track 13 of the bridge erecting machine is fixedly equipped with several components, the number of the components is determined with the length or the force change of the front traversing track of the bridge erecting machine, and the components are pressed between each other by a certain Arranged at intervals; the components include support accessories, adjustment devices and anti-tilt bases; integrally form a stepless adjustment ball-joint multi-leg bridge erecting machine front traversing track system; the system controls each adjustment screw 5 in the vertical direction Stepless adjustment is carried out so that the front traversing track 13 of the bridge erecting machi...

Embodiment 2

[0065] see figure 1 , 2, 3, 4, 5, 6, and 7, a stepless adjustment ball joint type multi-leg bridge erecting machine front traversing track system of the present invention, including the bridge erecting machine front traversing track 13, is characterized in that : the lower end surface of the front traversing track 13 of the bridge erecting machine is fixedly equipped with several components, the number of the components is determined with the length or the force change of the front traversing track of the bridge erecting machine, and the components are pressed between each other by a certain Arranged at intervals; the components include support accessories, adjustment devices and anti-tilt bases; integrally form a stepless adjustment ball-joint multi-leg bridge erecting machine front traversing track system; the system controls each adjustment screw 5 in the vertical direction Stepless adjustment is carried out so that the front traversing track 13 of the bridge erecting machi...

Embodiment 3

[0085] see figure 1 , 2, 3, 4, 5, 6, and 7, a stepless adjustment ball joint type multi-leg bridge erecting machine front traversing track system of the present invention, including the bridge erecting machine front traversing track 13, is characterized in that : the lower end surface of the front traversing track 13 of the bridge erecting machine is fixedly equipped with several components, the number of the components is determined with the length or the force change of the front traversing track of the bridge erecting machine, and the components are pressed between each other by a certain Arranged at intervals; the components include support accessories, adjustment devices and anti-tilt bases; integrally form a stepless adjustment ball-joint multi-leg bridge erecting machine front traversing track system; the system controls each adjustment screw 5 in the vertical direction Stepless adjustment is carried out so that the front traversing track 13 of the bridge erecting machi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Horizontal width | aaaaa | aaaaa |

| Horizontal width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com