Operator elevation and rotation bituminous coal burnt material serial triturating apparatus

A technology of bituminous coal burning objects and manipulators, which is applied in the field of analysis equipment for sulfur content in bituminous coal combustible substances, can solve the problems of difficult automatic measurement, high labor intensity of bituminous coal burning objects, and poor crushing effect, and achieves improvement. Mashing efficiency and mashing effect, compact structure, effect of improving mashing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

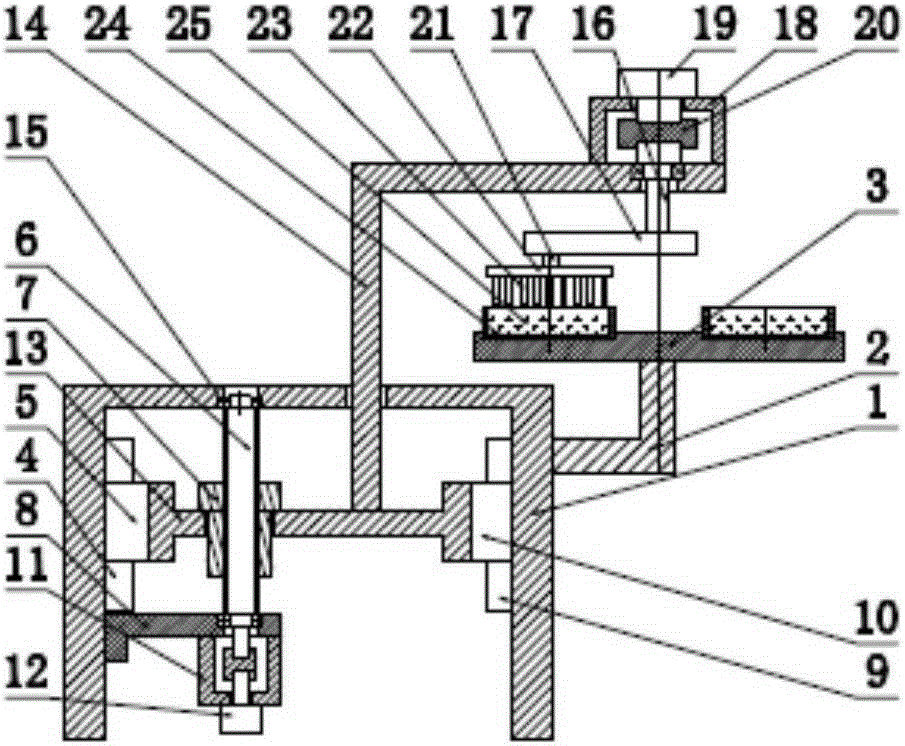

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] see figure 1 As shown, a kind of manipulator lifting and rotating bituminous coal burnt material serial crushing equipment of the present invention includes a manipulator lifting module, a manipulator rotating module, and a crucible tray 3 installed on the second L-shaped frame 2; The crucible tray 3 is equipped with n axisymmetrically distributed crucibles 24 , and the crucibles 24 are equipped with bituminous coal burning objects 25 .

[0014] see figure 1 As shown, the manipulator lifting module includes the first guide rail 4 installed on the U-shaped frame 1, the second guide rail 9 and the lower bracket 8, the first slide block 5 installed on the first guide rail 4, and the first slider 5 installed on the second guide rail 4. The second slide block 10 on the two guide rails 9, the two ends are respectively installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com