Improved scanning method for scanning probe microscope

A technology of scanning probes and scanning methods, which is applied in the direction of material analysis, measuring devices, and instruments using wave/particle radiation, which can solve problems such as wear, increase the cost of instrument use, and affect the service life of probes, so as to eliminate invalid wear Or loss, increase the service life, reduce the effect of using cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

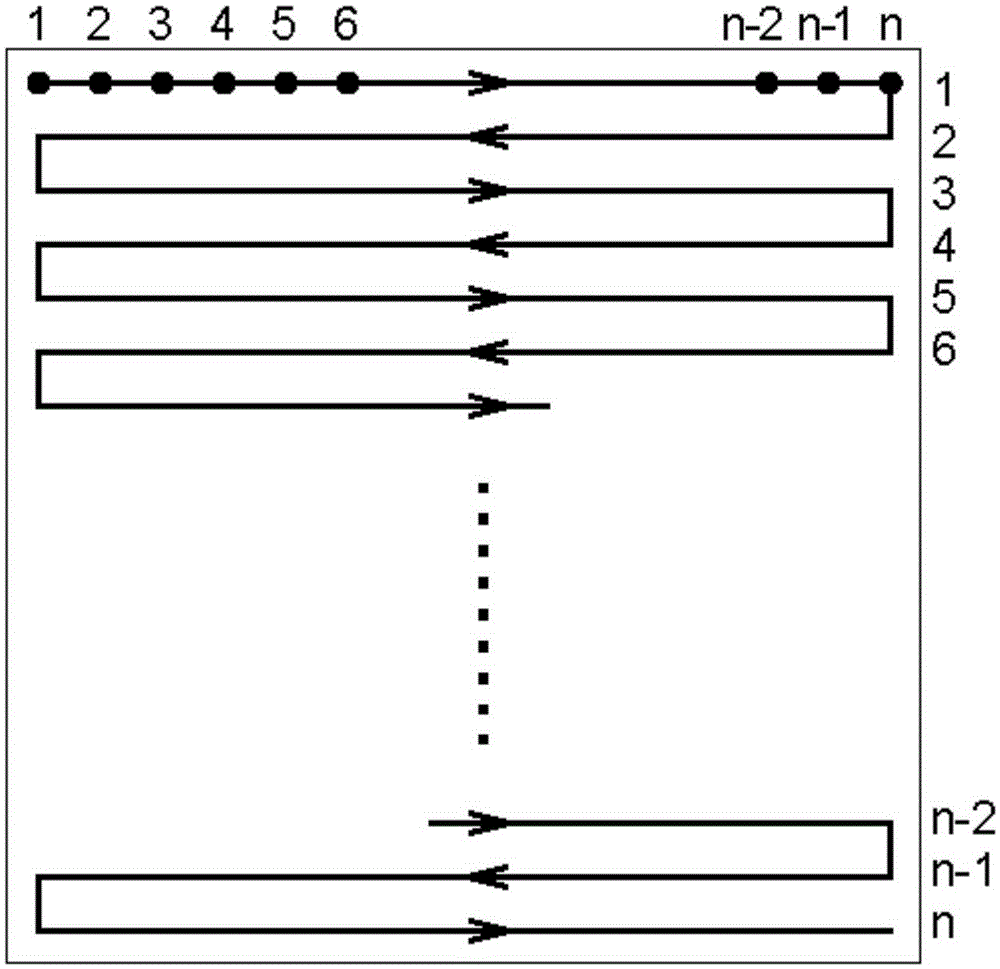

[0082] In the scanning probe microscope of this embodiment, when the scanning probe microscope detects the imaging, the probe is controlled to be separated from the sample in the return scanning path of the probe, and then the probe is controlled to be in contact with the sample after returning to the starting point, and the normal operation of the next line is started. to scan, such as Figure 5 Shown (the solid line is the forward scanning trajectory, and the dotted line is the return scanning trajectory).

[0083] from Figure 5 It can be seen that during detection and imaging, the scanning probe microscope separates the probe from the sample during a round-trip scanning process, which effectively eliminates the useless wear or loss of the needle tip, reduces the probability of the needle tip being contaminated by the sample, and improves the detection efficiency. needle life.

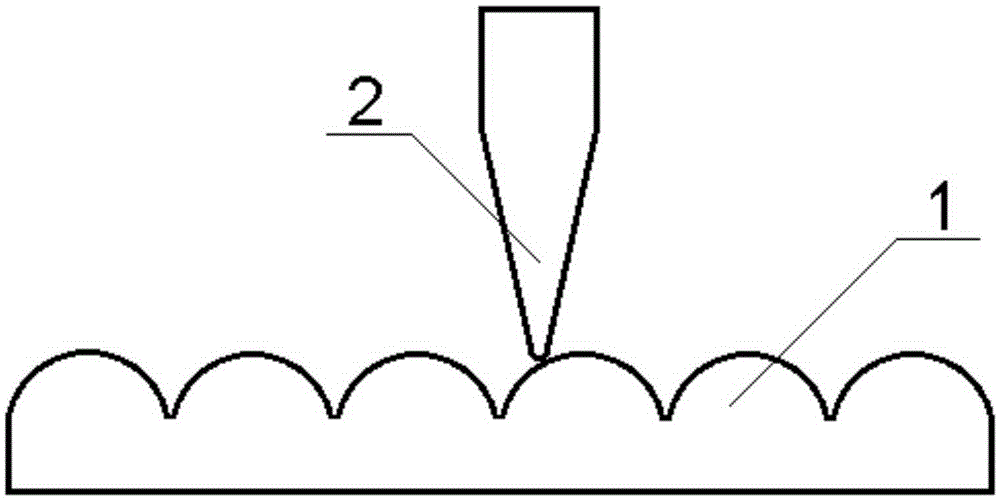

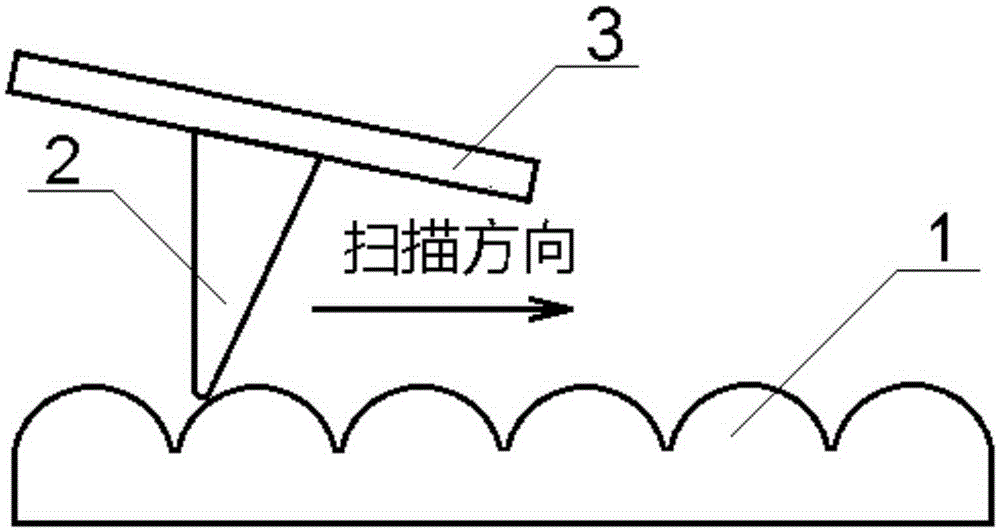

[0084] In this embodiment, an atomic force microscope is taken as an example to describe the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com