Structure of hydraulic breaker drill rod, and method for embedding alloy drill bit of hydraulic breaker drill rod

A technology of hydraulic breaker and alloy drill bit, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of consumption of impact force, loose drill bit, and reduced effective utilization of impact energy, so as to eliminate losses and process Easy installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

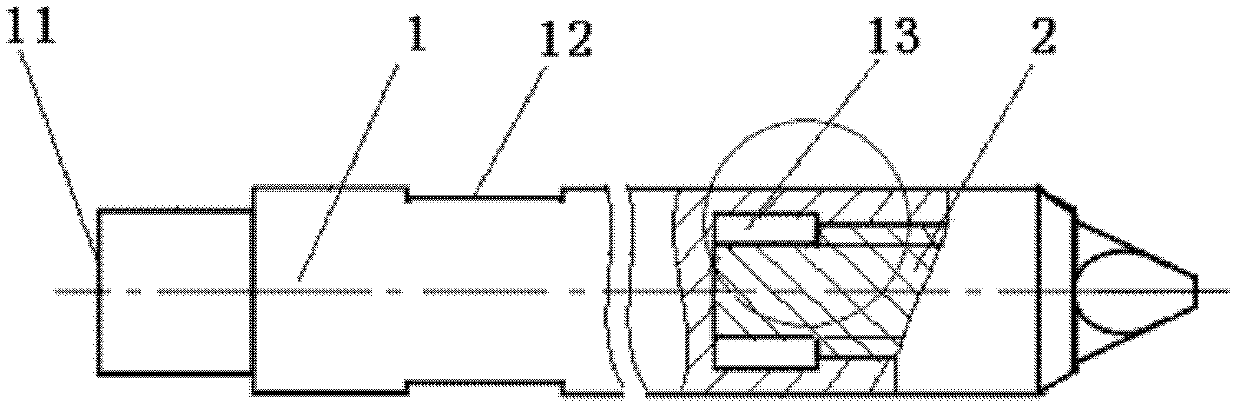

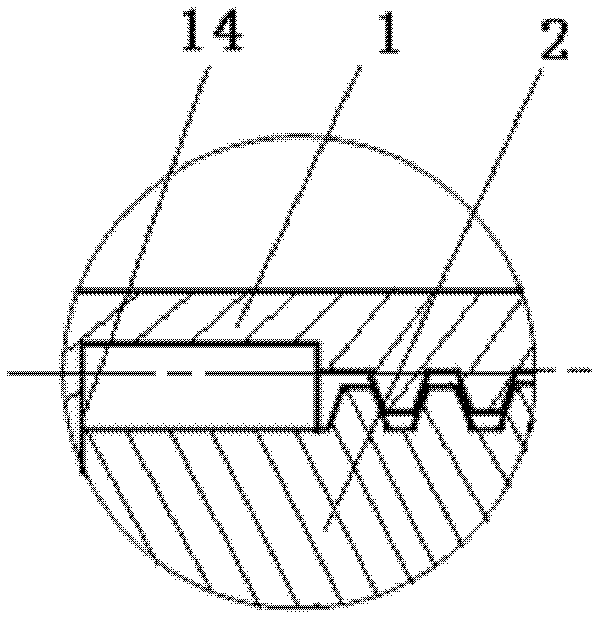

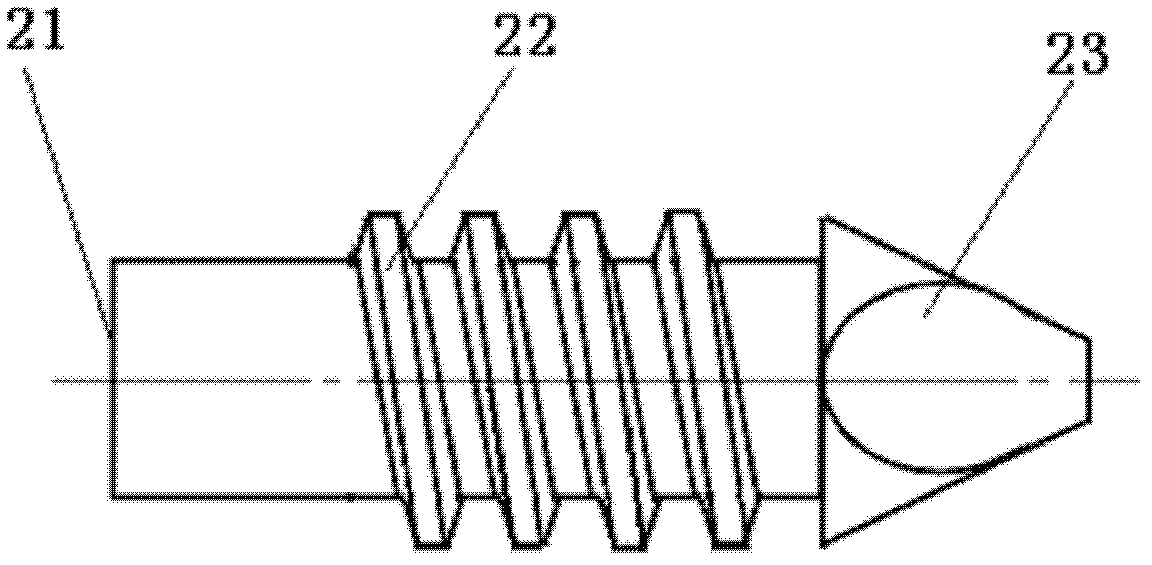

[0015] see figure 1 , This embodiment includes a drill rod body 1 and a drill bit 2 . The working end of the head of the drill rod body 1 is processed with a threaded central hole 13, which is a trapezoidal threaded hole. Tail impact surface 11. see image 3 , the drill bit 2 is made of hard alloy material, and its head is processed with a planar drill bit working edge 23, the middle part is a threaded screw 22, the threaded screw 22 is a trapezoidal threaded screw, and the tail end of the drill bit 2 is a drill bit impact Surface 21. Depend on figure 1 It can be seen that the threaded central hole 13 of the drill rod body 1 and the threaded screw 22 of the drill bit 2 form a thread pair, so that the drill bit 2 is embedded in the drill rod body 1, see figure 2 , The bottom surface 14 of the threaded central hole of the drill rod body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com