Testing and evaluating method for flatness of clothing in wear

An evaluation method and flatness technology, applied in image data processing, instruments, calculations, etc., can solve problems such as uncertain results, differences in flatness, and subjective evaluations that are easily affected by human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

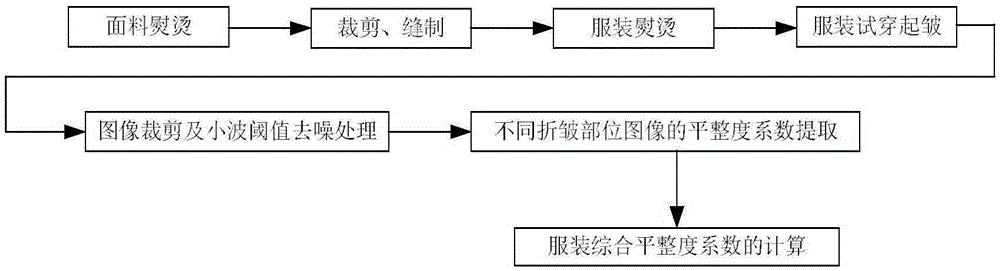

[0030] Such as figure 1 As shown, a method for testing and evaluating the flatness of clothing wearing, the specific steps are as follows:

[0031] Step 1. Select a number of fabrics to be tested with different flatness. After ironing and flattening, the fabrics to be tested are cut and sewed according to the uniform model, cutting and sewing conditions, and made into try-on clothes (consisting of tops and trousers). And iron it to make the surface flat and free of creases. In order to minimize the error and influence caused by manual operation, the above operation steps are all completed by the same person;

[0032] Step 2. Select a try-on with a suitable figure and size, and ask the try-on not to be too loose after wearing the try-on clothes. Because clothes that are too loose are not easy to wrinkle, the difference in test results is not o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com