Method and device for producing a shaped component

A technology for forming components and equipment, applied in the field of manufacturing forming components, can solve the problems of material failure, damage to economy, excessive material waste or scrap ratio, etc., to achieve high degree of deformation, avoid material waste, and reduce negative effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

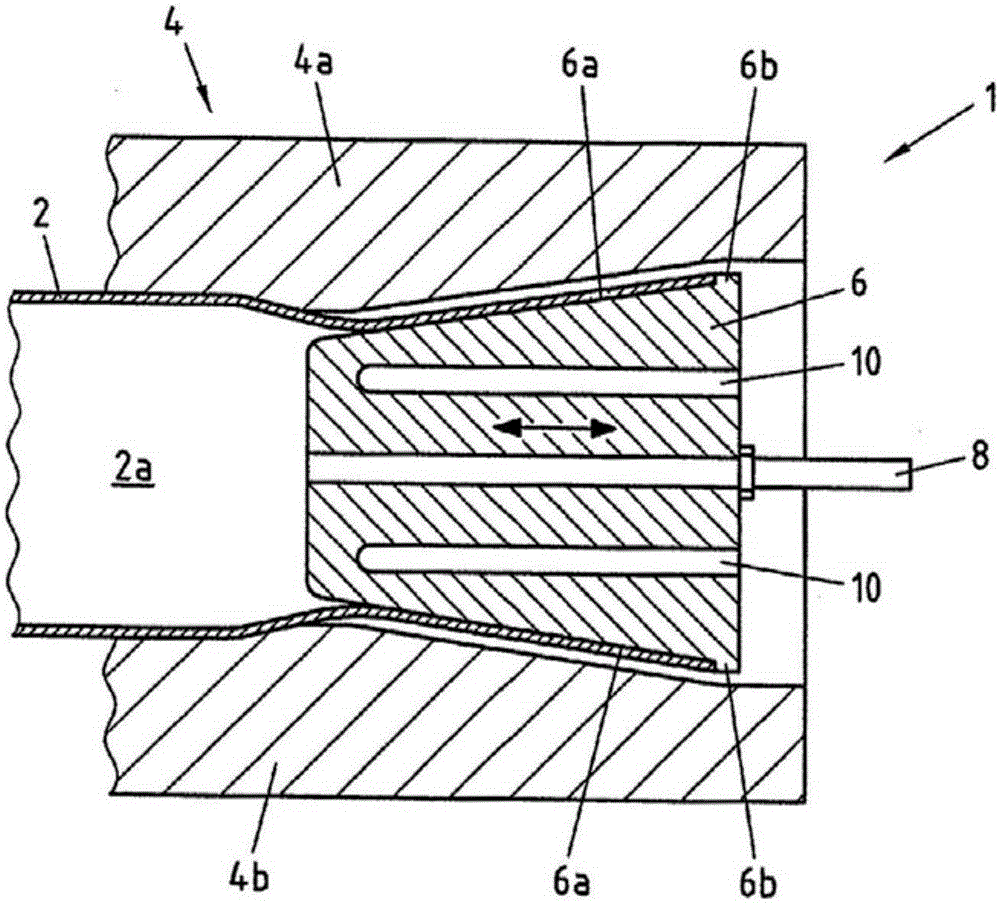

[0058] figure 1 A part of a first exemplary embodiment of a device 1 for shaping a workpiece 2 to produce a shaped component is shown in section. The workpiece 2 consists of hardenable steel and in this case is a tubular workpiece formed from a tubular profile. The workpiece 2 additionally has a hollow region 2a. The device 1 comprises a tool 4 having two shaped mold halves 4a and 4b and an axially displaceable butt punch 6 . The shape of the profile to be produced is determined by the shaped inner peripheral surfaces of the mold halves 4a and 4b. The workpiece 2 has already been inserted into the tool 4 , wherein the opening of the hollow region 2 a of the workpiece 2 is closed sealingly by the counter punch 6 . For this purpose, the counter punch 6 rests with its surface 6 a designed as a sealing region in a sealing manner against the inner circumference of the workpiece 2 in the end region. For this purpose, the counter punch 6 is adapted to the workpiece 2 and is in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com