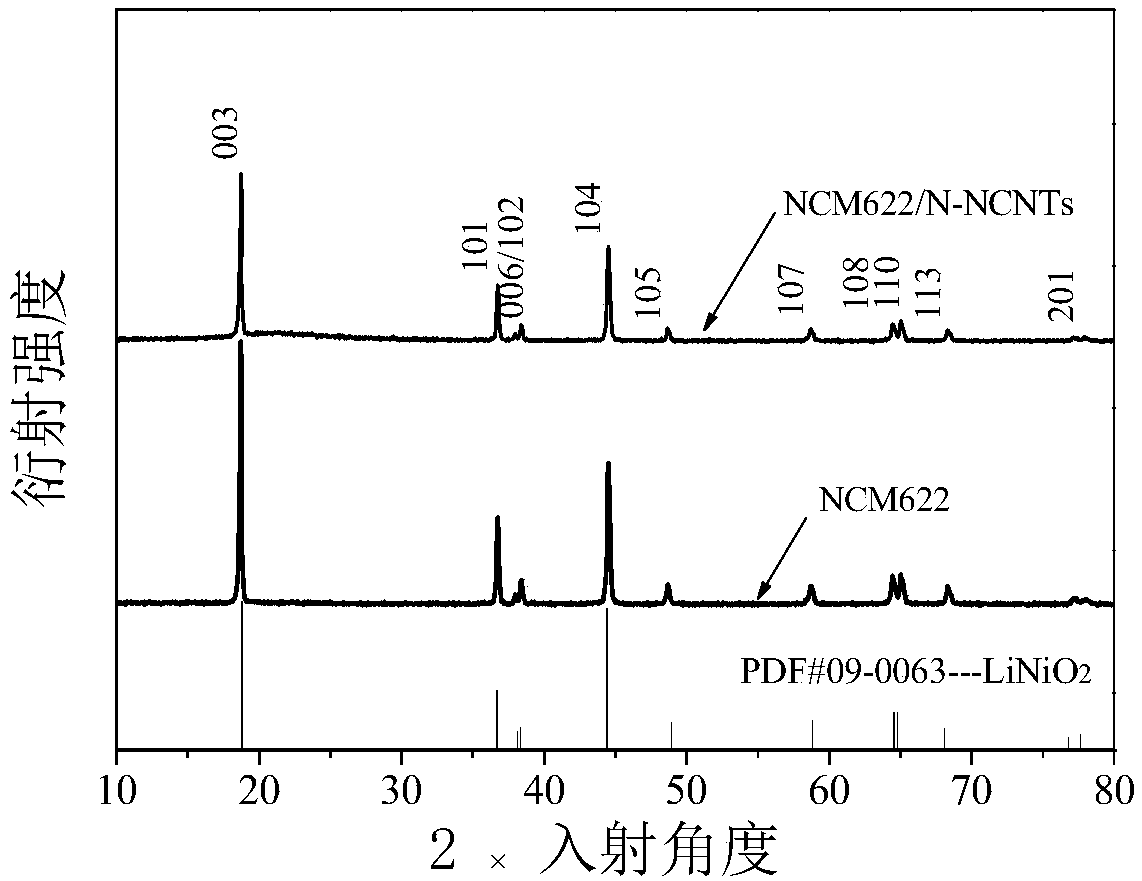

Multi-modified nickel-cobalt-manganese anode material and preparation method thereof

A cathode material, nickel-cobalt-manganese technology, applied in the field of multiple modified nickel-cobalt-manganese cathode materials and their preparation, can solve the problems of poor high-voltage cycle stability, poor high-rate stability, poor high-low temperature performance, etc., and achieve improved rate performance , easy to operate, reduce the effect of negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A multiple modified nickel-cobalt-manganese cathode material and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0032] Step 1: Dissolving the aluminum salt in isopropanol at a concentration of 0.05-0.07 mol / L to obtain solution I.

[0033] Step 2. According to the mass ratio of the aluminum salt to the nickel-cobalt-manganese positive electrode material being 1: (50-50.6), the nickel-cobalt-manganese positive electrode material is added to the solution I, at room temperature and 100-150 rpm Stir for 5-10 hours under the condition of 1 minute, then stir in a 60-80°C water bath and 100-150 rpm until the isopropanol evaporates; then place it in a blast drying oven and dry it at 90-100°C After 25-40 hours, a black powder was obtained.

[0034] Step 3. Put the black powder in a tube furnace and heat-treat it at 400-440°C for 4-5 hours to obtain the nickel-cobalt-manganese positive electrode material coated with alumina...

Embodiment 2

[0044] A multiple modified nickel-cobalt-manganese cathode material and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0045] Step 1: Dissolving the aluminum salt in isopropanol at a concentration of 0.06-0.08 mol / L to obtain solution I.

[0046] Step 2. According to the mass ratio of the aluminum salt to the nickel-cobalt-manganese positive electrode material being 1: (50.6-51.2), the nickel-cobalt-manganese positive electrode material is added to the solution I, at room temperature and 100-150 rpm Stir for 5-10 hours under the condition of 1 minute, then stir in a 60-80°C water bath and 100-150 rpm until the isopropanol evaporates; then place it in a blast drying oven and dry it at 90-100°C After 25-40 hours, a black powder was obtained.

[0047] Step 3. Put the black powder in a tube furnace and heat-treat it at 415-455° C. for 4-5 hours to obtain the nickel-cobalt-manganese positive electrode material coated with alu...

Embodiment 3

[0062] A multiple modified nickel-cobalt-manganese cathode material and a preparation method thereof. The steps of the preparation method described in this embodiment are:

[0063] Step 1: Dissolving the aluminum salt in isopropanol at a concentration of 0.07-0.09 mol / L to obtain solution I.

[0064] Step 2. According to the mass ratio of the aluminum salt to the nickel-cobalt-manganese positive electrode material being 1: (51.2-51.8), the nickel-cobalt-manganese positive electrode material is added to the solution I, at room temperature and 100-150 rpm Stir for 5-10 hours under the condition of 1 minute, then stir in a 60-80°C water bath and 100-150 rpm until the isopropanol evaporates; then place it in a blast drying oven and dry it at 90-100°C After 25-40 hours, a black powder was obtained.

[0065] Step 3. Put the black powder in a tube furnace and heat-treat it at 430-470° C. for 4-5 hours to obtain the nickel-cobalt-manganese positive electrode material coated with alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com