A method of using magnetic field to promote high production of antimicrobial peptides by Bacillus amyloliquefaciens

A technology of amylolytic spores and antimicrobial peptides, applied in high-yield antimicrobial peptides and biological fields, to achieve the effects of reducing production costs, simple structure, and convenient magnetic field treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

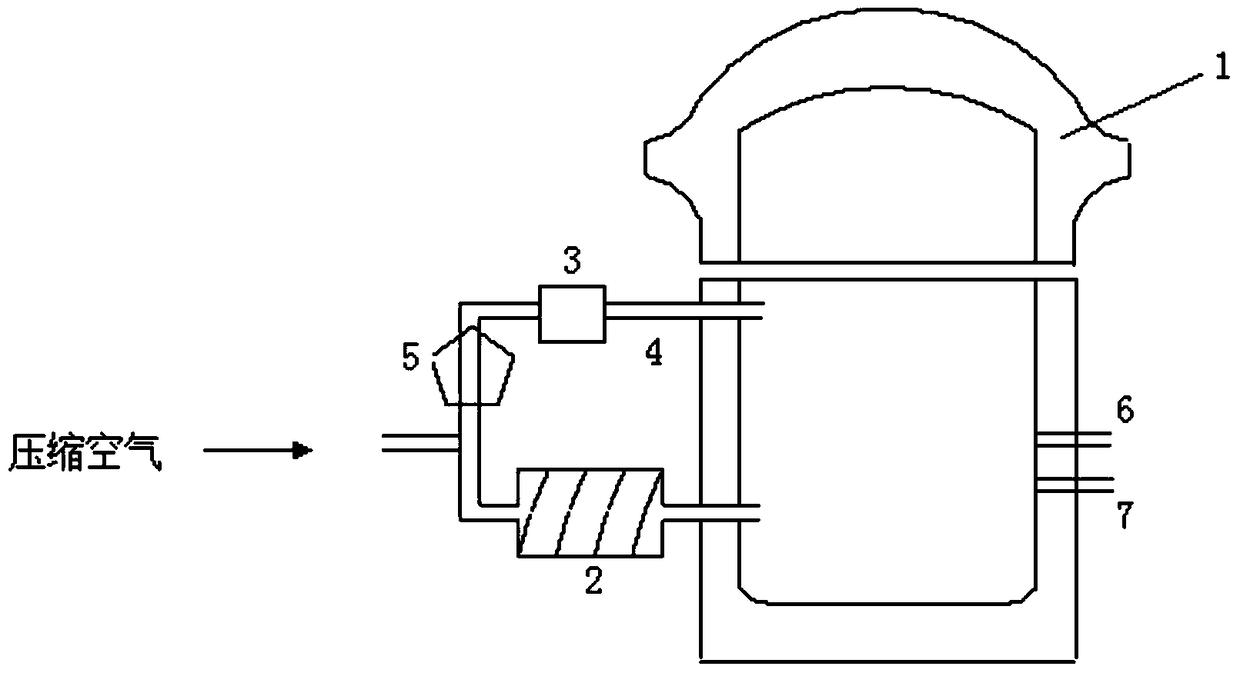

[0048] Such as Figure 4 The shown fermentation culture device for promoting the high production of antimicrobial peptides by Bacillus amyloliquefaciens includes a fermenter body 1, and the fermenter body 1 is provided with a circulation reflux device, and a magnetic induction coil 2 is provided on the circulation reflux device.

[0049] The circulation return device includes a circulation return pump 3 and a circulation return pipeline 4 , and a liquid flow meter 5 is arranged on the circulation return pipeline 4 .

[0050] The fermenter body 1 is provided with a dissolved oxygen detection device 6 and a pH detection device 7 .

[0051] A kind of method utilizing magnetic field to promote Bacillus amyloliquefaciens high-production antimicrobial peptide, the steps are as follows:

[0052] (1) Inoculate the activated Bacillus amyloliquefaciens into the seed medium, and culture the seeds for 18 hours at 35°C and 200 rpm to obtain the seed solution;

[0053]In described step (1...

Embodiment 2

[0083] As described in Example 1, the method of utilizing a magnetic field to promote high-production antimicrobial peptides by Bacillus amyloliquefaciens, the difference is that the steps are as follows:

[0084] (1) Inoculate the activated Bacillus amyloliquefaciens into the seed medium, and culture the seeds for 16 hours at 40°C and 320rpm to obtain the seed solution;

[0085] In described step (1), every liter of component of seed culture medium is as follows:

[0086] Starch 20g, yeast powder 5g, potassium phosphate 4g, magnesium sulfate 3g, manganese sulfate 0.001g, pH 6.5, dilute to 1L with deionized water;

[0087] (2) Transfer the seed liquid prepared in step (1) to the fermentation medium at a ratio of 5% (volume percentage), and ferment for 10 hours initially at 25°C, stirring speed 100rpm, and air flow 0.5vvm. The cells entered the logarithmic growth phase, and then under the conditions of 25°C, stirring speed of 100rpm, and air flow rate of 0.5vvm, they were ferm...

Embodiment 3

[0110] A kind of method utilizing magnetic field to promote Bacillus amyloliquefaciens high-production antimicrobial peptide, the steps are as follows:

[0111] (1) Inoculate the activated Bacillus amyloliquefaciens into the seed medium, and culture the seeds for 24 hours at 25°C and 100 rpm to obtain the seed liquid;

[0112] In described step (1), every liter of component of seed culture medium is as follows:

[0113] Glucose 40.0g, yeast powder 20.0g, potassium phosphate 1.0, magnesium sulfate 0.5g, manganese sulfate 0.001g, pH 6.5, deionized water to 1L;

[0114](2) Transfer the seed solution prepared in step (1) to the fermentation medium at a ratio of 1% (volume percentage), and ferment for 8 hours at 30° C., stirring speed 180 rpm, and air flow 0.8 vvm, and the thalline The cells enter the logarithmic growth phase, and then under the conditions of 30°C, stirring speed 180rpm, and air flow rate 0.8vvm, they undergo a magnetic field fermentation treatment with a current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com