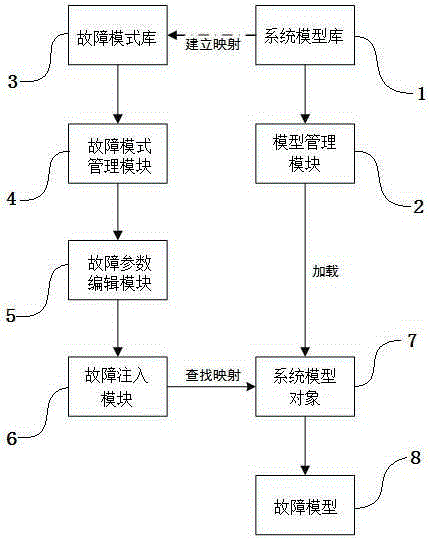

Modelica model-based fault injection system and method

A fault injection and model technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low efficiency, difficulty in maintaining model consistency, difficulty in modifying and expanding model behavior, etc., to achieve consistency, The effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

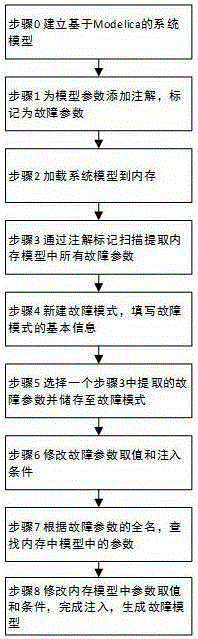

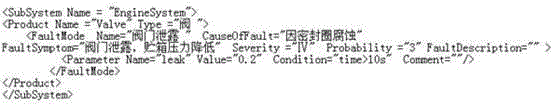

[0065] Step 0) Establish a pipeline model based on Modelica and store it in the system model library; the text of the pipeline model is as follows:

[0066]

[0067] Step 1) Add annotation annotations to the parameters in the pipeline model, marked as fault parameters; it can be seen from the text of the pipeline model, where the leak parameter is added with annotaiton(__Mworks(FaultInfo(FaultParameter)));

[0068] Step 2) Load the pipeline model into the memory through the model management module, and generate the pipeline model object of the pipeline model by parsing the pipeline model;

[0069] Step 3) Scan all annotation information through the model management module, and extract parameters marked with special annotation annotations in the pipeline model;

[0070] Step 4) Create or edit a failure mode, fill in the basic information of the failure mode, and store the failure mode in the failure mode library;

[0071] Step 5) The failure mode management module selects a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com