Intelligent process for lead-acid storage battery

A technology of lead-acid batteries and batteries, which is applied in the field of intelligent technology, can solve the problems of unsmooth connection of battery intelligent technology in battery production process, influence on follow-up operation, leakage of sealant, etc. performance, enhanced insulation safety, and the effect of preventing oxidative deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

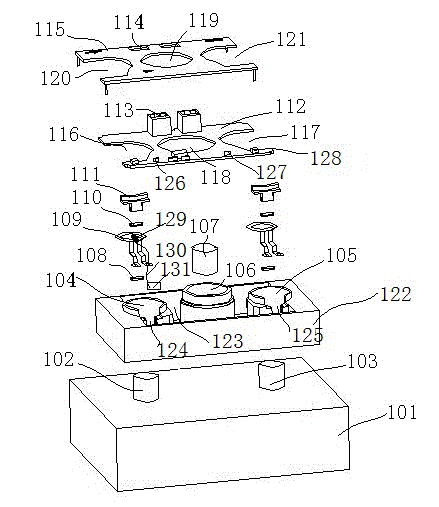

[0020] The following is a detailed description of the battery intelligent process in conjunction with the accompanying drawings, which specifically includes the following steps:

[0021] (a) Make the terminal connection piece 109, the battery cover 122 and the measurement circuit board 112:

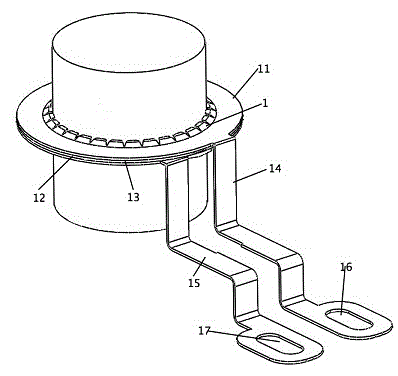

[0022] The structure of the terminal connecting piece 109 is as follows figure 2 As shown, the terminal connecting piece 109 is formed by insulating and connecting the terminal collar 11 and the terminal collar 12 with each other. There are ratchets 1 distributed on the inner side, and the ratchets 1 are generally isosceles triangles or isosceles trapezoids. For the convenience of installation in the future, the ratchets 1 can be lifted upward at an angle of 15 to 45 degrees. A first lead piece 14 is connected to the outside of the terminal collar 11 , and a second lead piece 15 is connected to the outside of the terminal collar 12 . In one embodiment of the present invention, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com