Heat dissipating type cable protection pipe resistant to compression and tension

A cable protection tube and heat dissipation technology, which is applied to electrical components and other directions, can solve the problems of poor heat dissipation effect of the cable protection tube and low tensile and compressive strength of the cable protection tube, so as to improve the service life, improve the working performance, and ensure the work. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

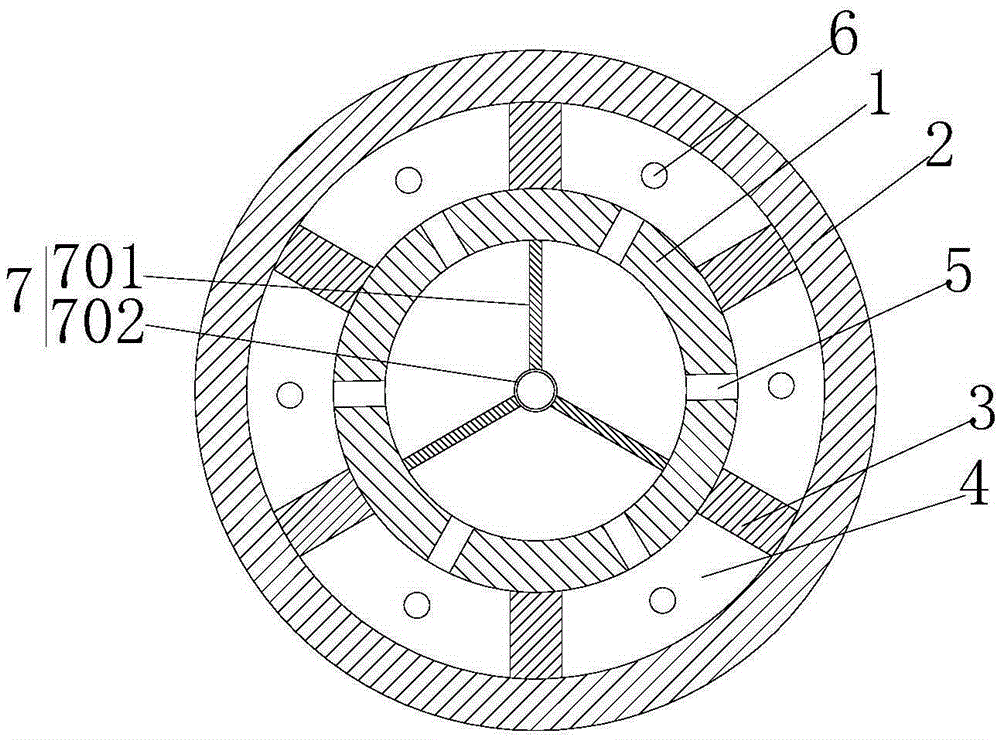

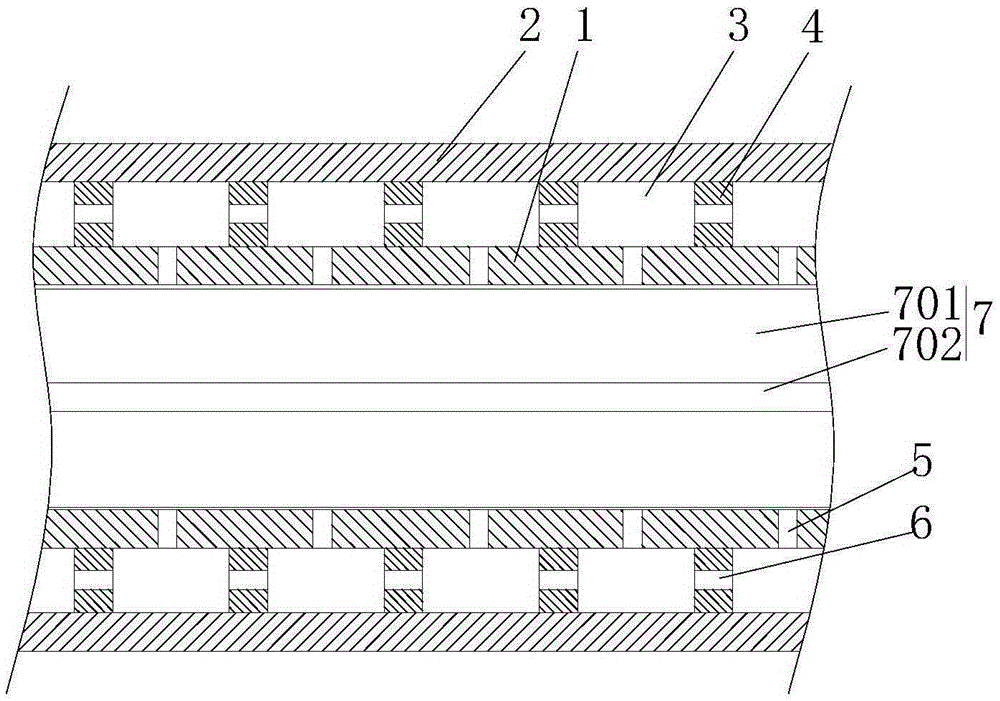

[0020] Such as figure 1 , figure 2 as shown, figure 1 It is a schematic diagram of the cross-section structure of a heat-dissipating type anti-pressure and tensile cable protection tube proposed by the present invention; figure 2 It is a structural schematic diagram of the longitudinal section of a heat-dissipating type compressive and tensile cable protection tube proposed by the present invention.

[0021] refer to figure 1 , figure 2 , a heat-dissipating anti-compression and tensile cable protection tube proposed by the present invention includes an inner tube 1, an outer tube 2, longitudinal ribs 3 and transverse ribs 4.

[0022] The inner tube 1 is arranged in the outer tube 2 and coaxial with the outer tube 2, the longitudinal ribs 3 and the transverse ribs 4 are arranged between the inner tube 1 and the outer tube 2, the longitudinal ribs 3 extend along the axial direction of the tube, and surround the inner tube 1 in a Radial arrangement, the transverse ribs 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com