Vehicle body having two adhesively bonded body components

A body and component technology, applied to vehicle parts, superstructure, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

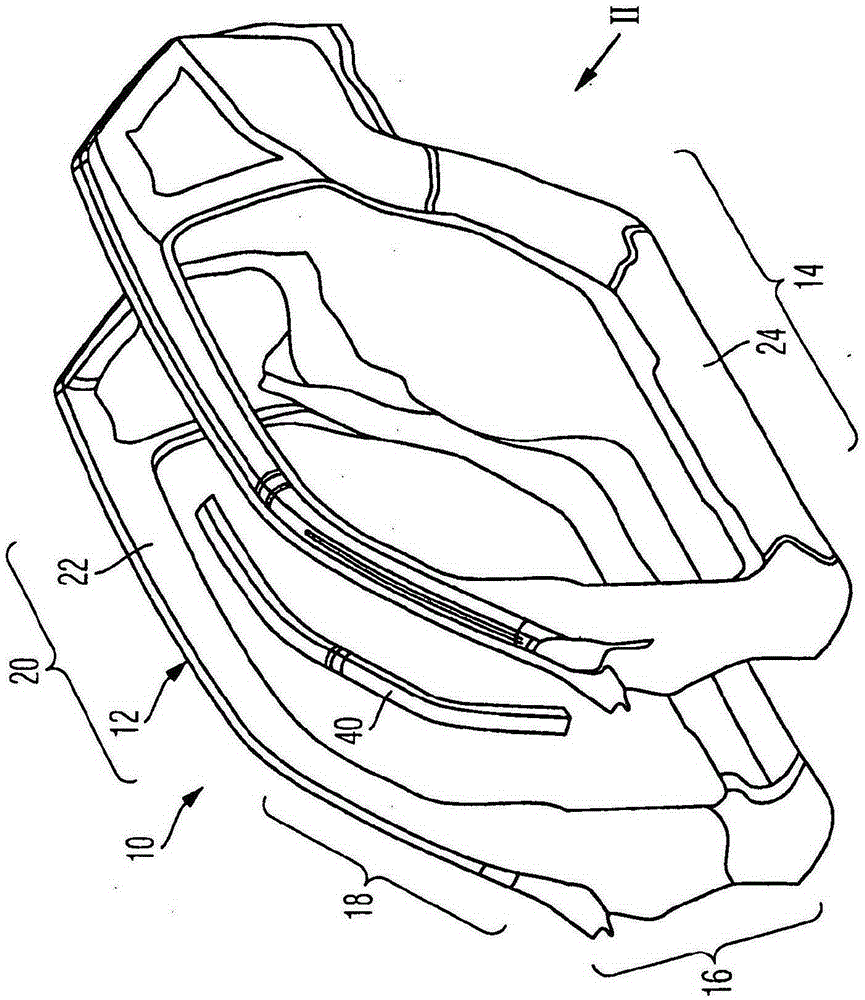

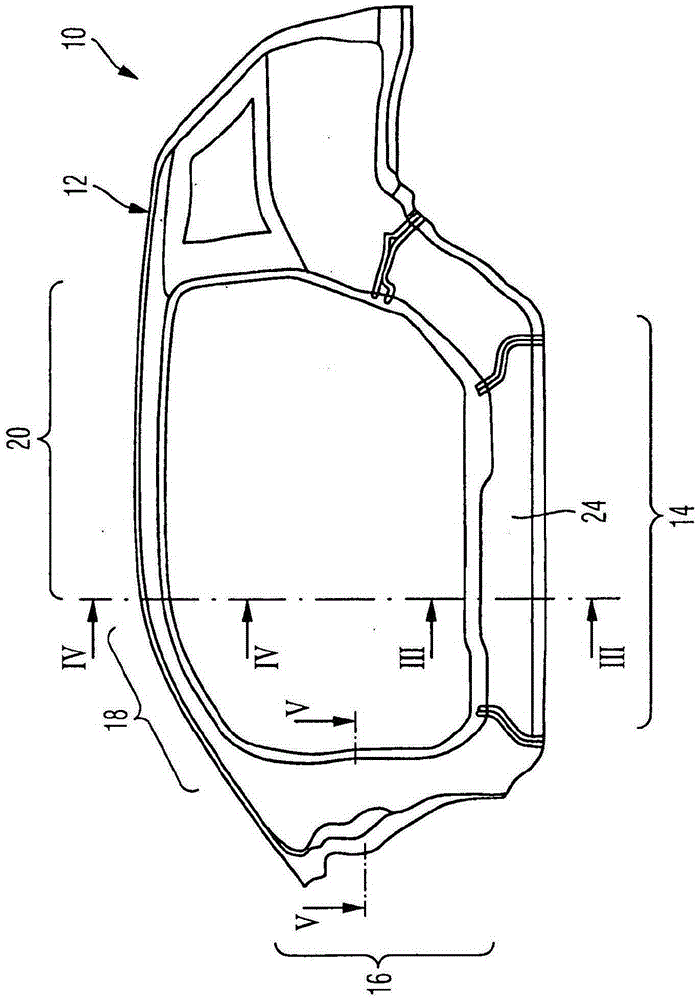

[0020] The vehicle body 10 of the passenger car has side walls or side frames 12 as the main part of its passenger compartment. The side frame 12 forms a ring laterally on the vehicle body 10 , with which ring the occupants in the passenger compartment are particularly protected not only in the event of a frontal impact on the vehicle body 10 but also in the event of a side impact on the vehicle body. The side frame 12 comprises, for the associated vehicle, a lower door sill or rocker area 14 , a front wall or a wall area 16 , a front A-pillar or an A-pillar area 18 , and an upper vehicle body. Roof rail or roof rail region 20 .

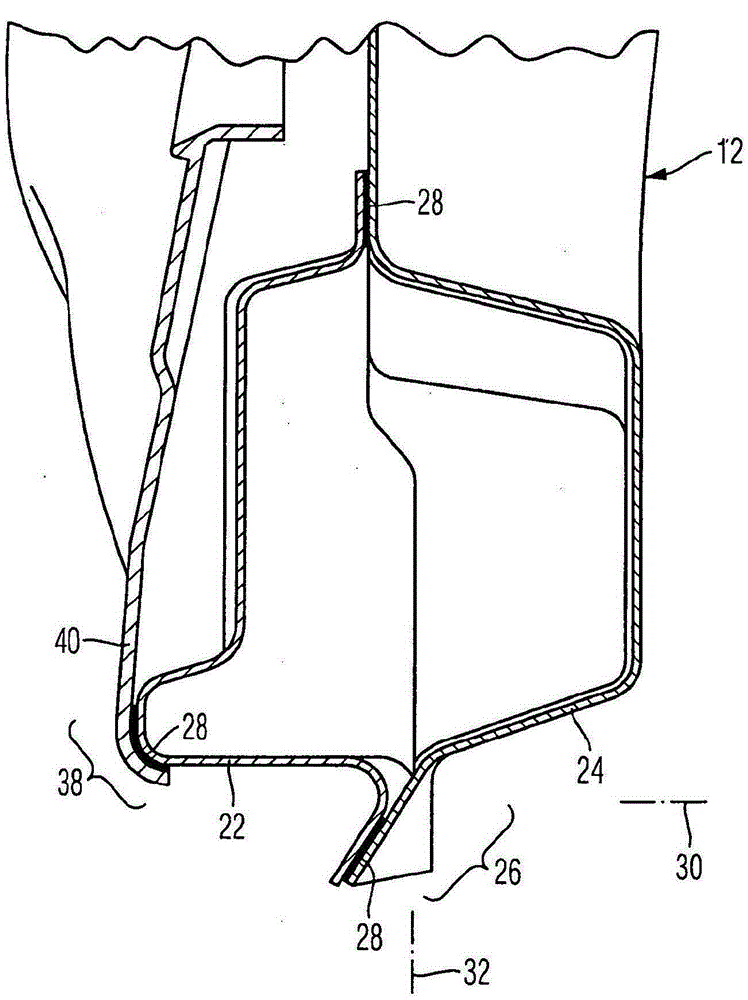

[0021] The side frame 12 is formed from an inner side frame shell 22 and an outer side frame shell 24 , which are each produced as thin-walled body components in the form of structural thin shells from fiber-reinforced plastic.

[0022] The two side frame shells 22 and 24 are glued to one another at strip-shaped, likewise thin-walled adhesive flange...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap