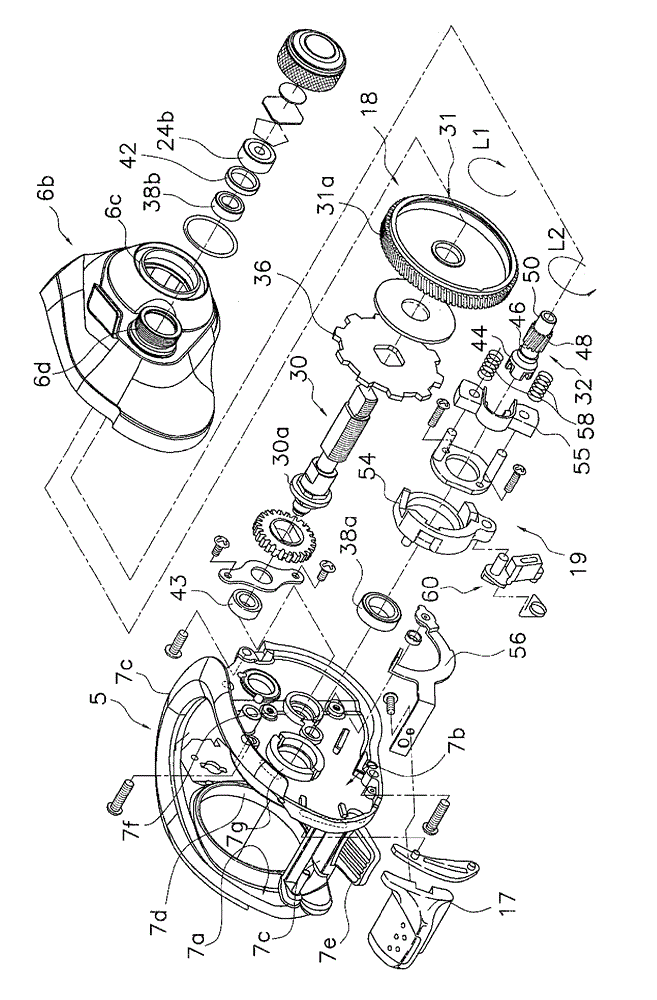

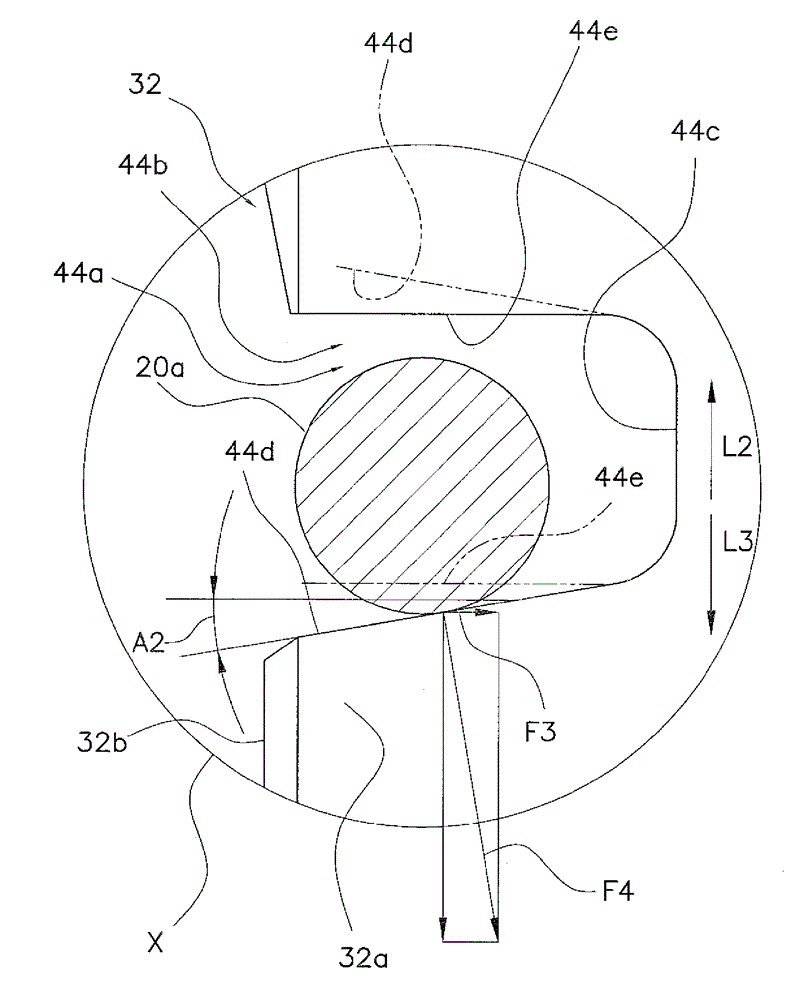

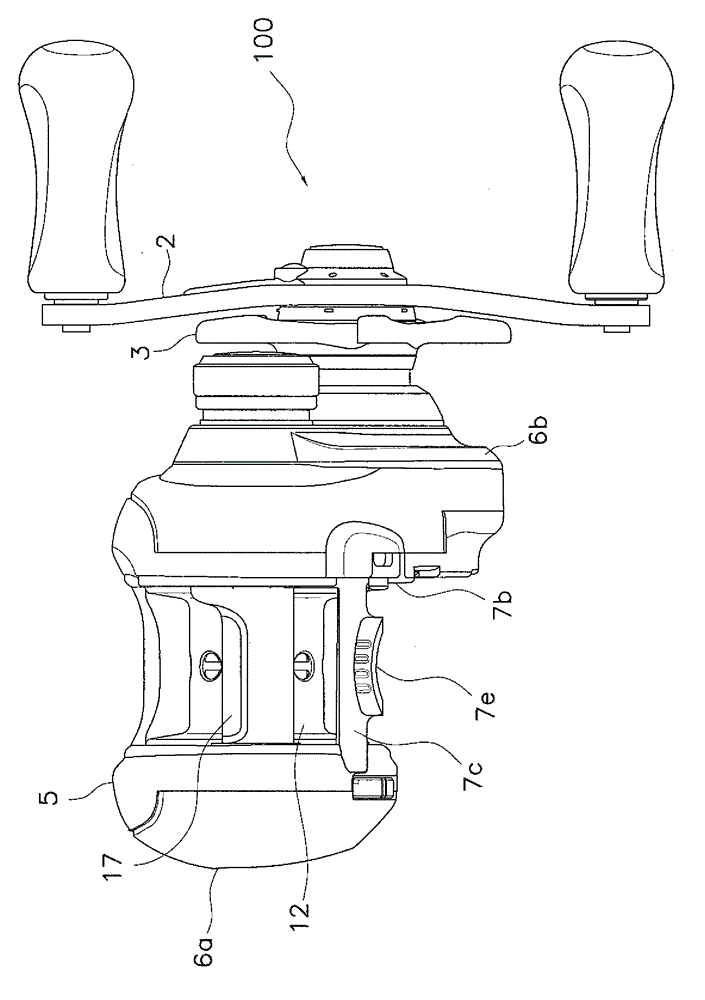

Dual-bearing reel and clutch mechanism thereof

一种离合器机构、绕线轮的技术,应用在钓鱼用绕线轮、捕鱼、应用等方向,能够解决斜齿作用力增大、分离、不能迅速离合器等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0085] An embodiment of the present invention has been described above, but the present invention is not limited to the above-described embodiment, and various changes can be made within a range not departing from the gist of the invention. In particular, a plurality of embodiments and modifications described in this specification can be combined arbitrarily as necessary.

[0086] (a) In the above embodiment, the pinion gear 32 is rotatably and axially movable supported by the reel main body 1 via two bearings, but the present invention is not limited thereto. The present invention can also be applied to a structure in which the pinion is rotatably and axially movable by only one bearing.

[0087] (b) In the above embodiment, the outer diameter of the constricted portion 46 is larger than the outer diameter of the second support portion 50 , but the outer diameter of the constricted portion 46 may be smaller than the outer diameter of the second support portion 50 instead.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com