Anti-slip shoe

A non-slip and shoe body technology, applied in the field of shoe manufacturing, can solve problems such as walking hard, discounted anti-slip effect, and slippery soles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

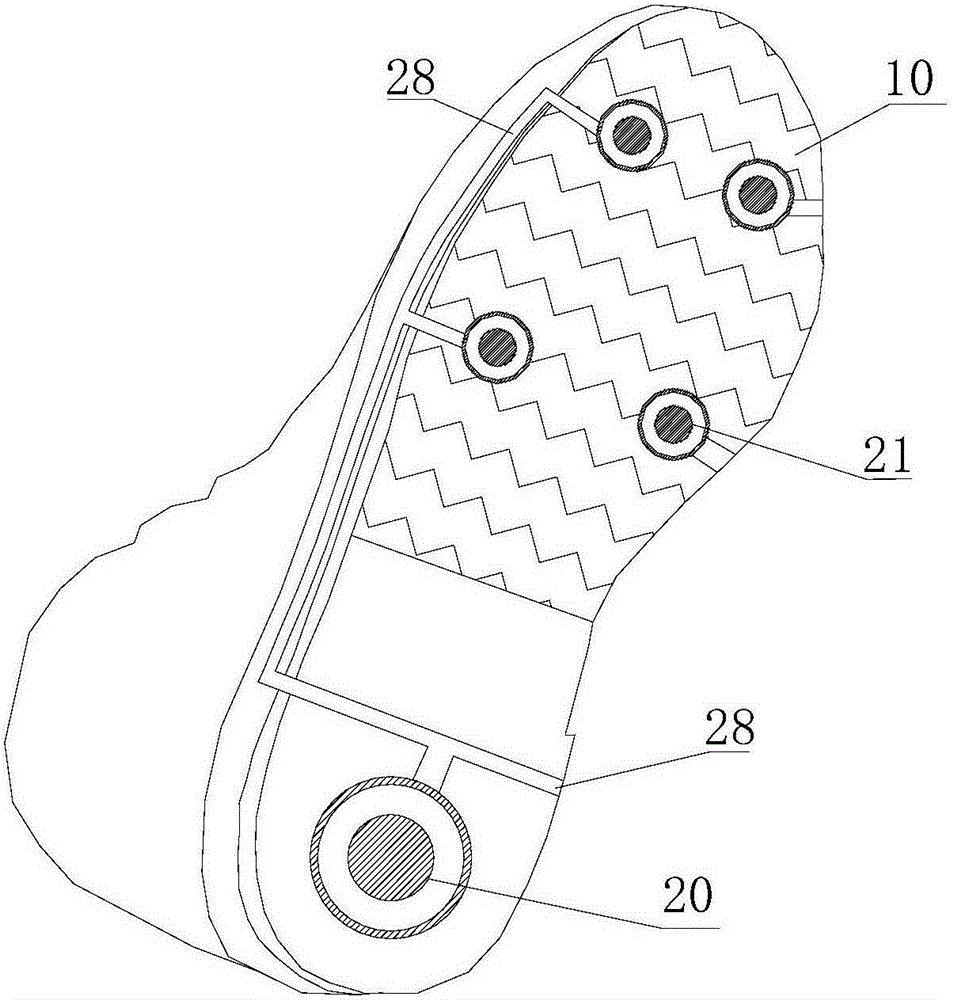

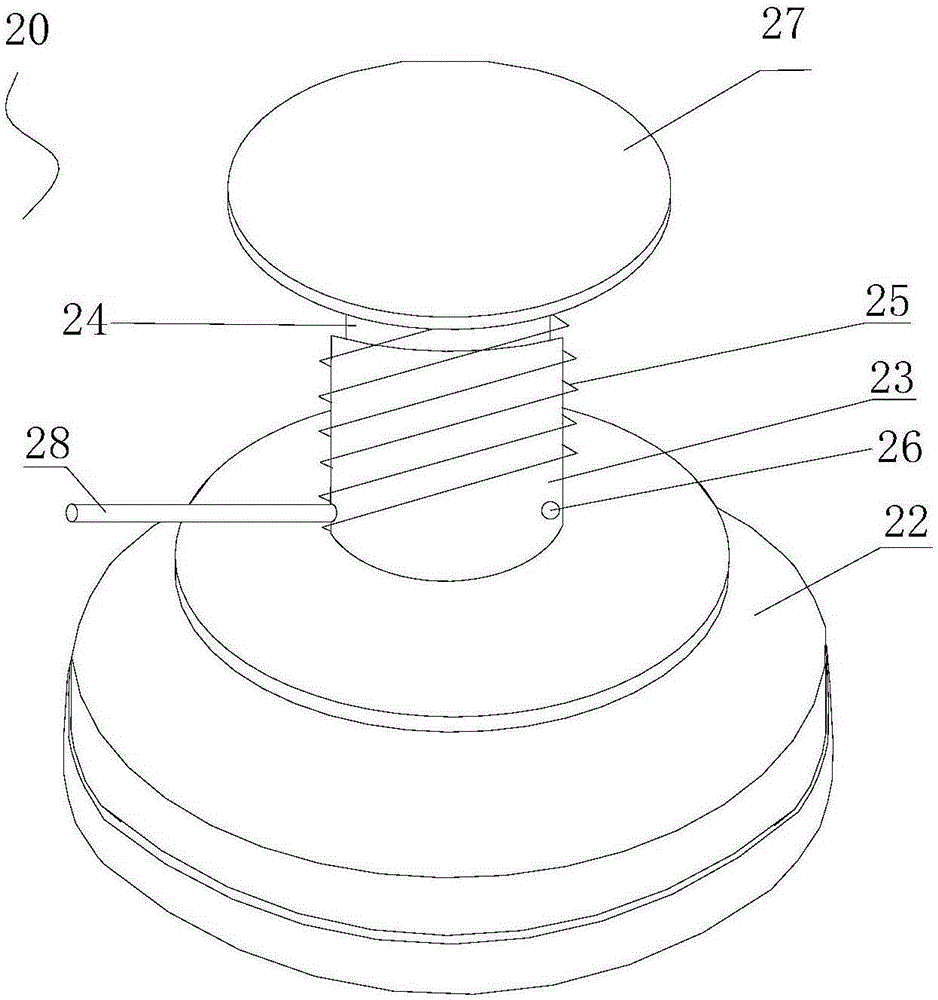

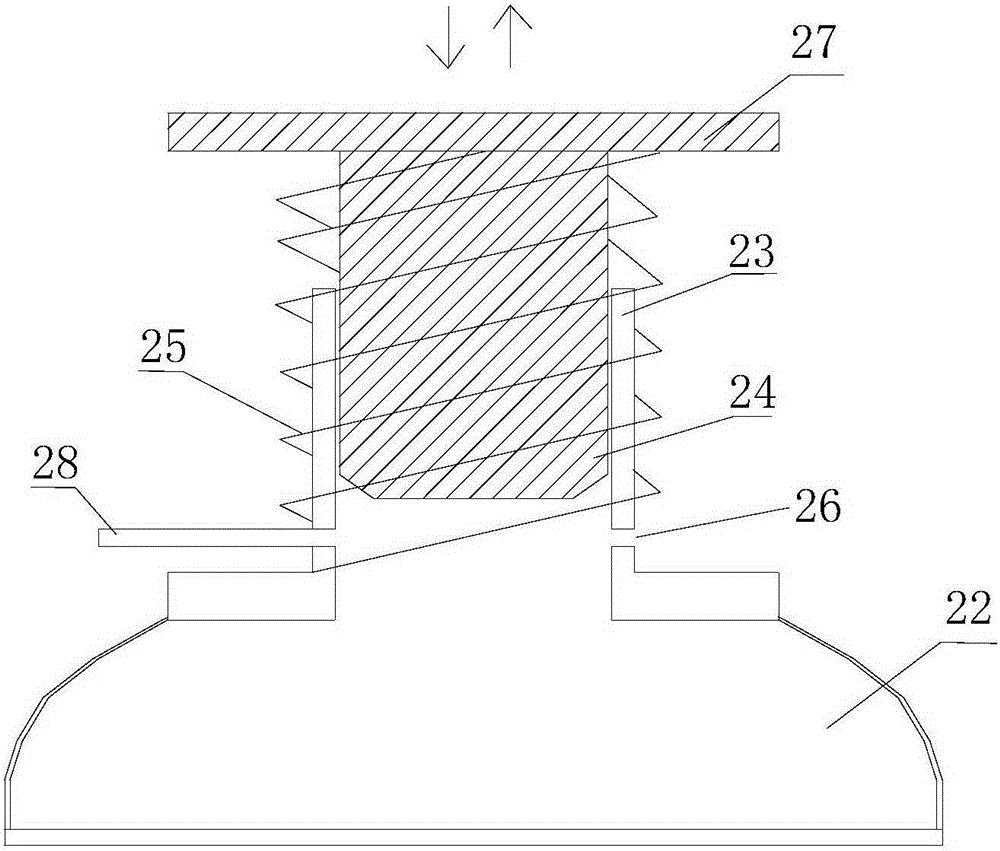

[0010] Please also see figure 1 , figure 2 and image 3 , figure 1 is a perspective view of the anti-skid shoes of the present invention, figure 2 is a picture

[0011] Schematic diagram of the structure of the anti-skid mechanism in 1, image 3 yes figure 1 Sectional view of the middle anti-skid mechanism. The bottom of the forefoot of the sole 10 of the non-slip shoes is provided with a plurality of auxiliary suction cups 21 with the adsorption surface facing downward, and an anti-slip mechanism 20 is arranged in the rear palm of the sole 10, and the auxiliary suction cups 21 pass through the vent pipes 28 on the edges of both sides of the sole. It communicates with the anti-skid mechanism 20 .

[0012] The anti-slip mechanism 20 includes a main suction cup 22 , a ventilator 23 , a sliding rod 24 and a return spring 25 . The ventilation cylinder 23 is tightly fitted on the top surface of the main suction cup 22 , and two through holes 26 are symmetrically arranged ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap