Cast blade upset head blanking forming piece

A blade and heading technology, which is applied in the field of forging blade heading blanks, can solve the problems of wasting raw materials, reducing the life of the mold, and collapsing the mold transfer R, so as to improve the metallurgical performance, reduce the cross-sectional area, and distribute uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

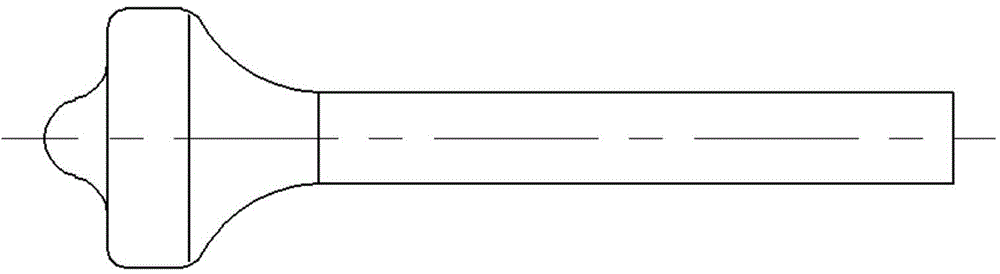

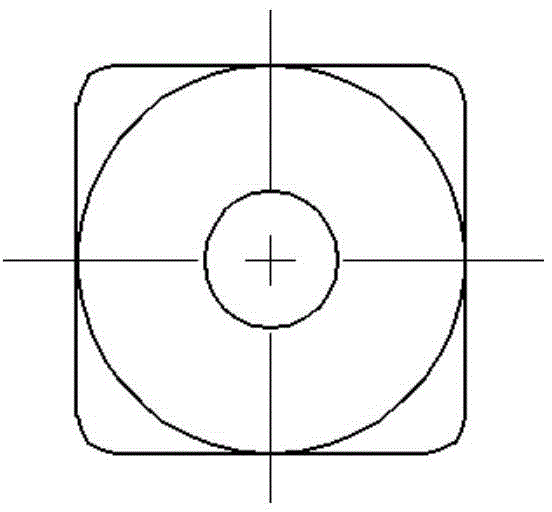

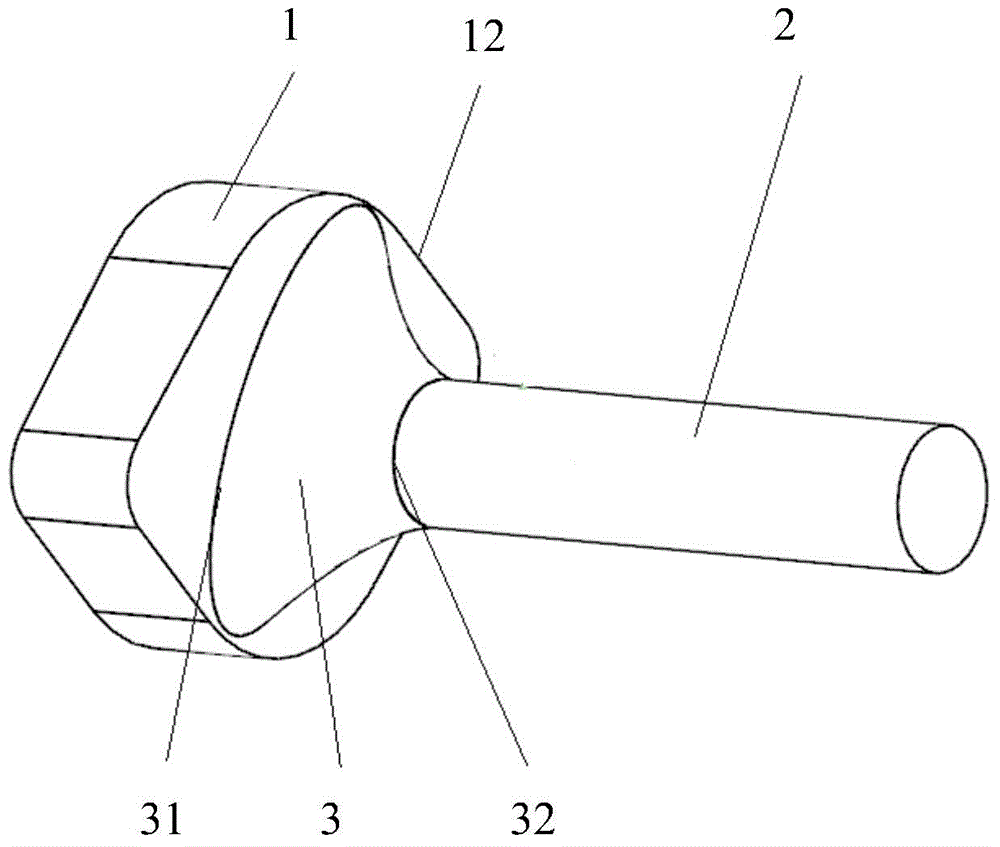

[0029] 1. Upsetting head design: The head is designed as a rectangle, and the two diagonal corners close to the inlet and outlet sides of the blade root are connected by a large R to reduce the metal material and match the head of the pre-forging die; The transition area between the head of the upsetting piece and the rod is designed as follows: the transition area is formed by three cross-sections, and the cross-sectional shapes are two ellipses with the long axis in the same direction as the blade inlet and outlet sides, and one with the diameter and diameter of the rod. A circle with the same center; the transfer area is formed by the above two ellipses and a circle using the "through curve group" command in the modeling software. The finally obtained upsetting piece is the cross section of the transition area from the head to the rod gradually transitions from an ellipse to a circle, the head and the transition area transition smoothly through the transition R, and the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com