Center bracket for solid propellant reshaping

A solid propellant and center bracket technology, applied in the field of mechanical processing, can solve problems such as inability to process, and achieve the effects of high processing precision, convenient and fast locking, and easy tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

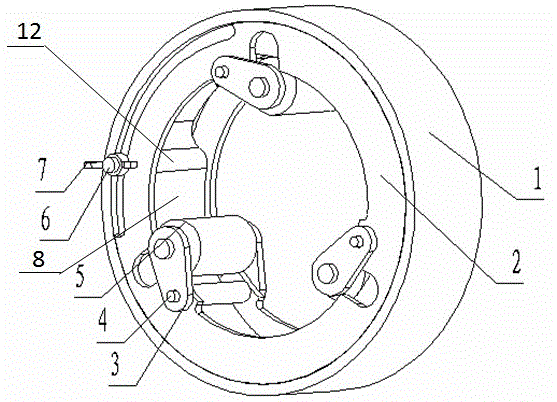

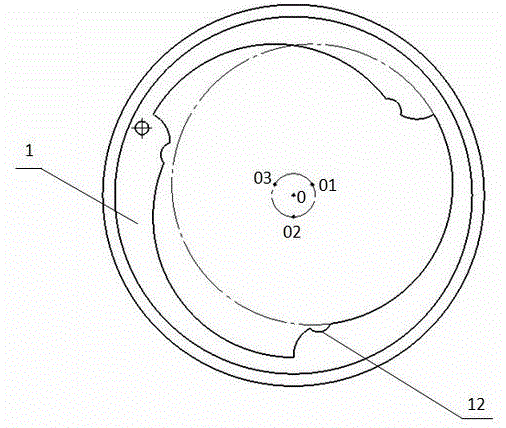

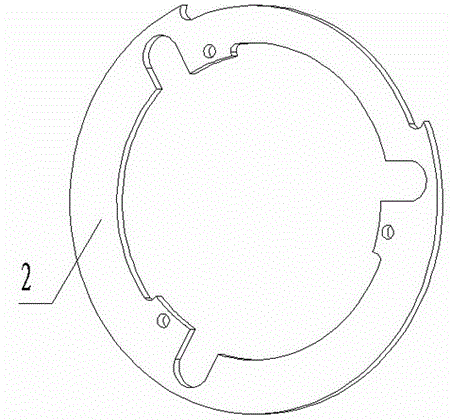

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the three rollers 5 are fixed on the connecting rings 2 on both sides of the center bracket main body 1 by connecting the swing device 3; The roller 5 rolls on the centripetal rail 8, which can change the inner clamping diameter of the center bracket. The two ends of the eccentric centripetal rail 8 are 5-8mm lower than the two ends of the center bracket main body 1, forming a groove 9 of 5-8mm, and the connecting rings 2 on both sides of the center bracket main body 1 are respectively placed in the groove 9. The center O of three evenly distributed eccentric centripetal rails 8 1 , O 2 , O 3 On a circle with the center O of the center bracket body 1 as the center, the eccentricity O-O 1 , O-O 2 , O-O are 12-15mm respectively, in order not to hinder the normal use of the roller 5, the eccentric centripetal rail 8 is processed with a circular arc 12 transition.

[0019] Three evenly distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com