High-speed elbow polishing machine

A polishing machine and elbow technology, which is used in grinding/polishing equipment, grinding machine tools, grinding machine parts, etc., can solve the problems of insufficient grinding, insufficient inner wall grinding, and difficulties, and achieve automatic grinding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

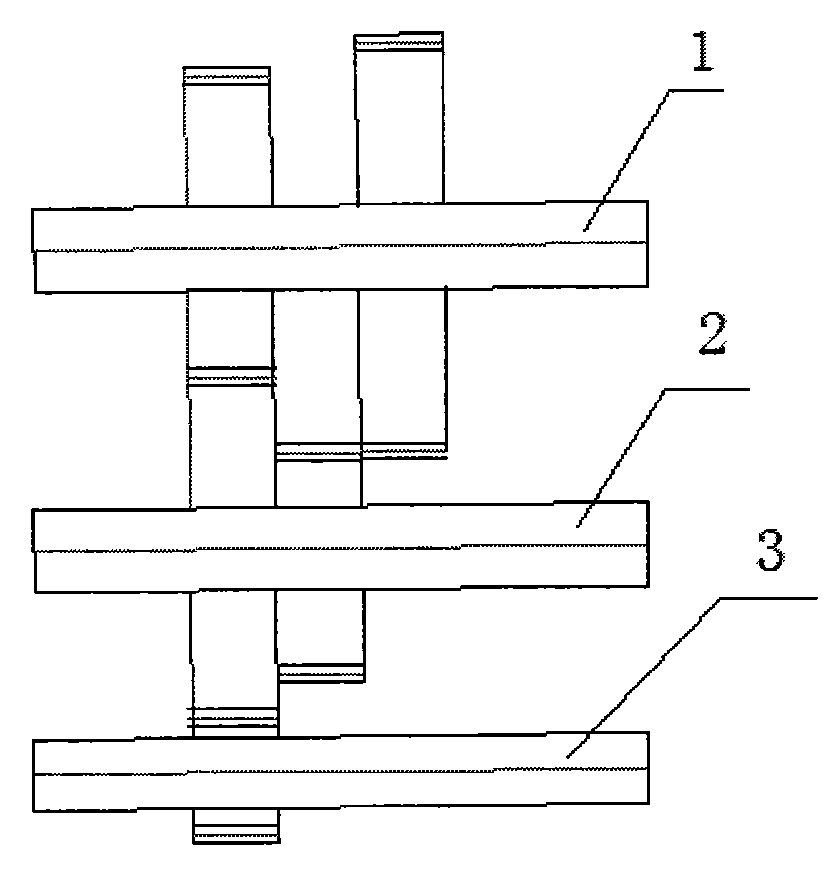

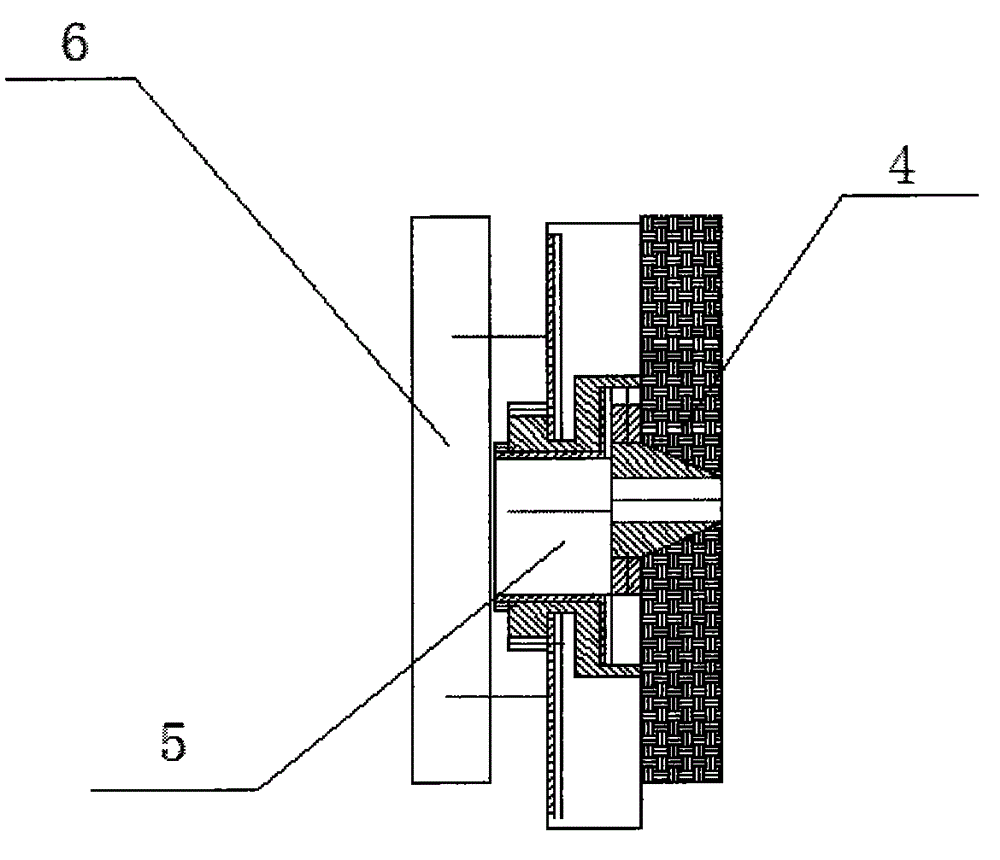

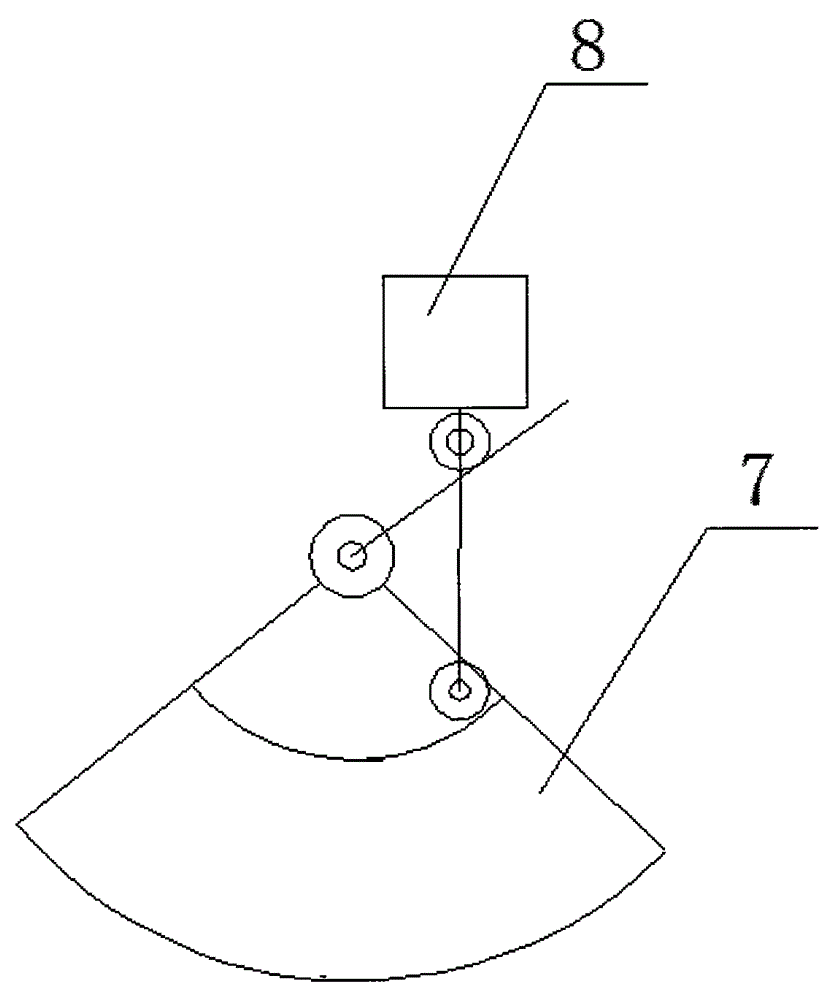

[0010] The present invention designs a high-speed elbow polishing machine, which is composed of a gearbox, a grinding device and an elbow fastening device. Key shaft two 2 and spline shaft three 3 are provided with two gears of 30 teeth and 38 teeth on spline shaft one 1, and spline shaft one 1 can move along the direction of the spline shaft through the handle; There are two gears with 30 teeth and 22 teeth on the 2, and an 18-tooth gear on the spline shaft 3 3. Among them, the spline shaft 2 and the spline shaft 3 3 are fastened and immovable. When the motor input is At 3000 rpm, the spline shaft 1 can be controlled by the handle, and the gears on the three spline shafts can be used to easily switch between 0 rpm, 5000 rpm and 8600 rpm; the grinding device consists of a chassis 4, an eccentric sleeve 5, an elbow and a cloth wheel The sand disc 6 is composed of the chassis 4, the eccentric sleeve 5 and the cloth wheel sand disc 6 arranged in sequence, and one end of the elbow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com