Coaxial counter-acting force torque wrench drive tensioner

A reaction force and tensioner technology, applied in the directions of wrenches, wrenches, screwdrivers, etc., can solve the problems of shortening the service life of bolts, uneven loading of bolts, easy air leakage and water leakage, etc., to ensure torque accuracy, avoid The effect of lateral eccentric load and avoiding deformation and fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

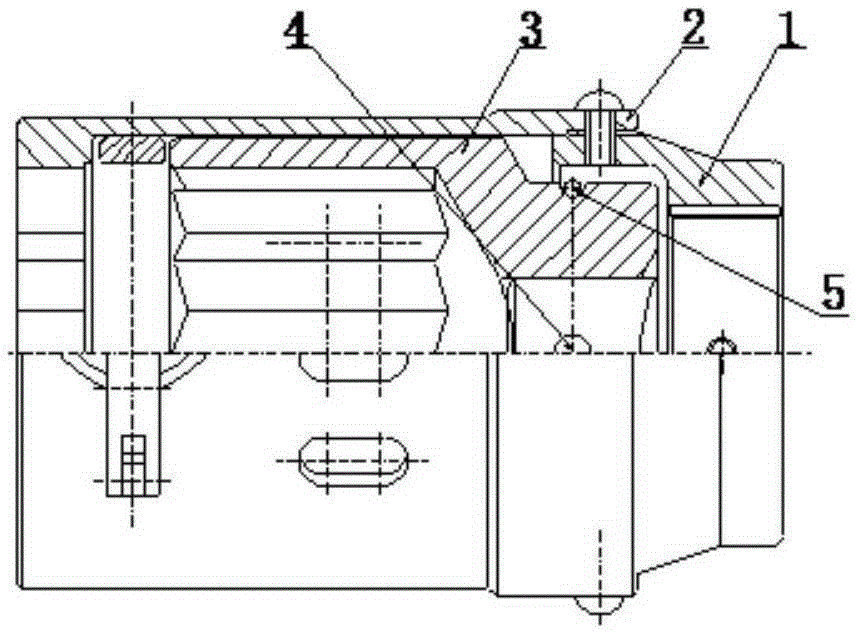

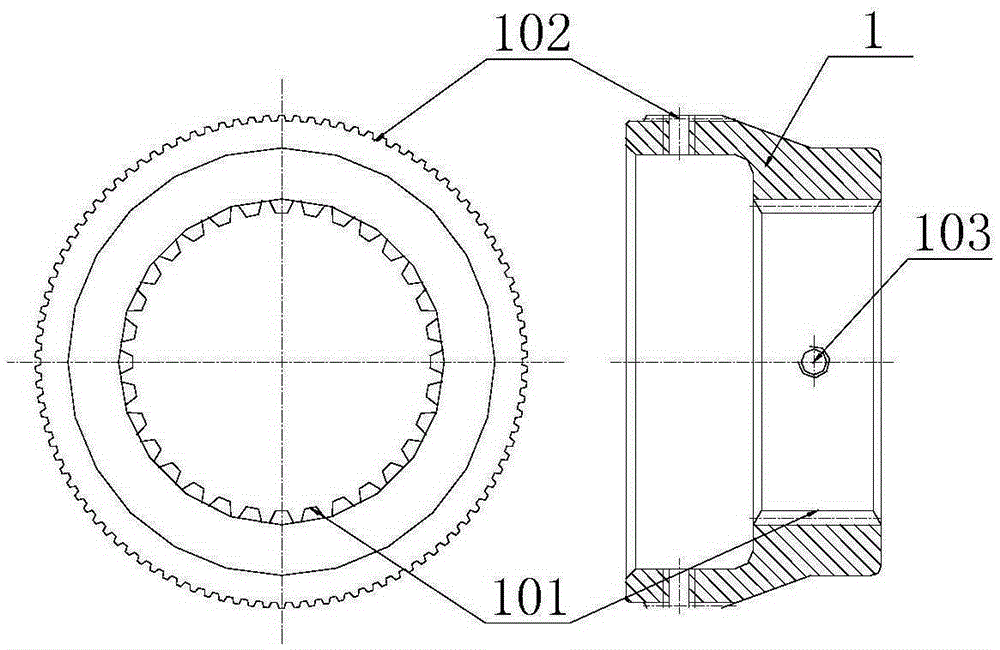

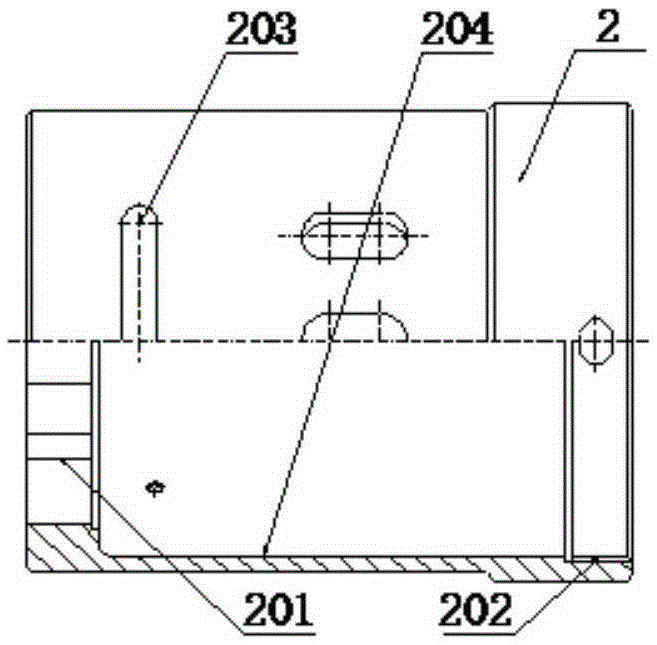

[0029] Such as Figure 1-11 Shown is a coaxial reaction force torque wrench drive stretcher, which is used in conjunction with a torque wrench and includes an outer sleeve 2, an inner sleeve 3 and a connecting sleeve 1. Such as Figure 3-5 The jacket 2 shown is a cylindrical structure, the lower opening of the jacket 2 is an inner polygonal opening 201 or an inner tooth-shaped opening 201.1, and the upper opening of the jacket 2 is provided with an inner tooth-like or inner keyed spline structure 202, The inner wall between the upper and lower openings in the outer shell 2 is a smooth inner wall 204; the lower side opening of the outer shell 2 can be designed in a hexagonal or a dodecagonal shape. The lower end of the jacket 2 is also provided with a locking mechanism 6, such as Figure 8-10 The lock mechanism 6 shown includes a connecting lock 8 located inside the outer jacket 2, a left lock 7 located at the left end of the connecting lock 8 and hinged 9 with it, a right lock 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com