Split tracked vehicle

A tracked vehicle and split-type technology, applied to tracked vehicles, motor vehicles, vehicle parts, etc., can solve the problems of inconvenient operation, poor practicability, speed regulation and high power per hour, etc., and achieve increased safety factor and stability, convenient use, Control precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

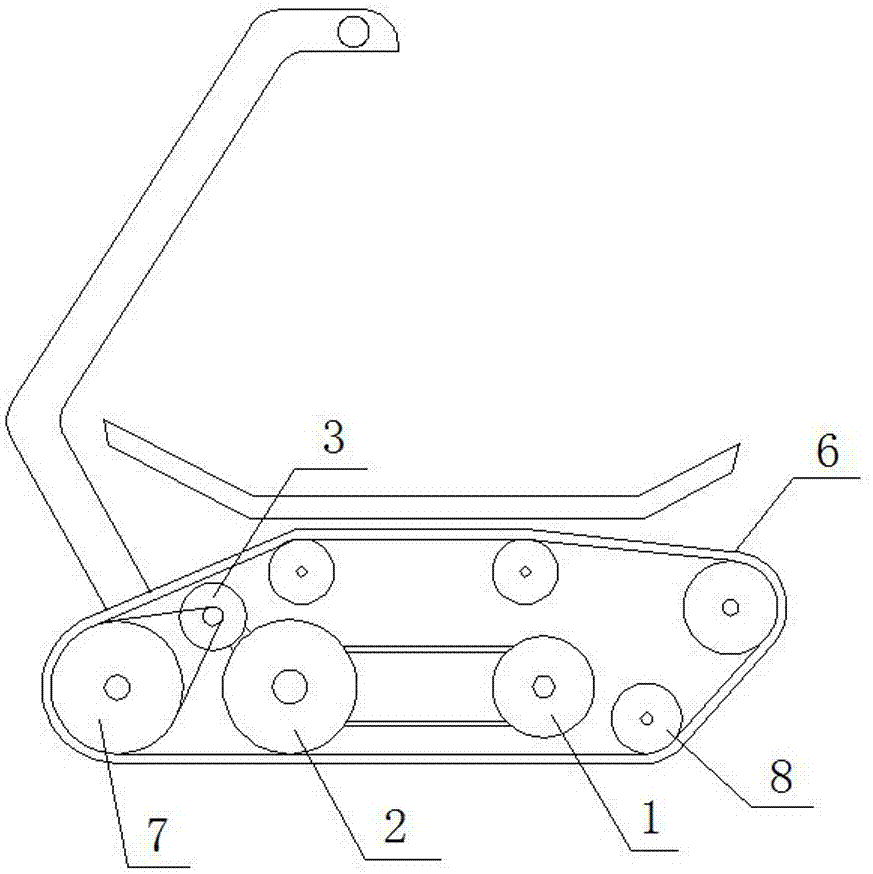

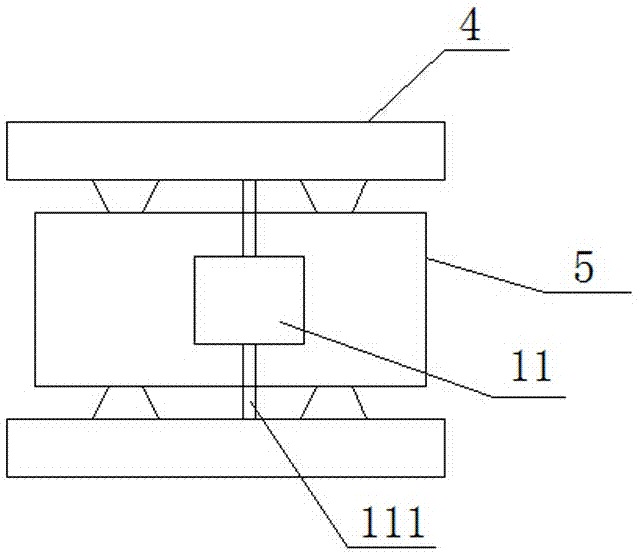

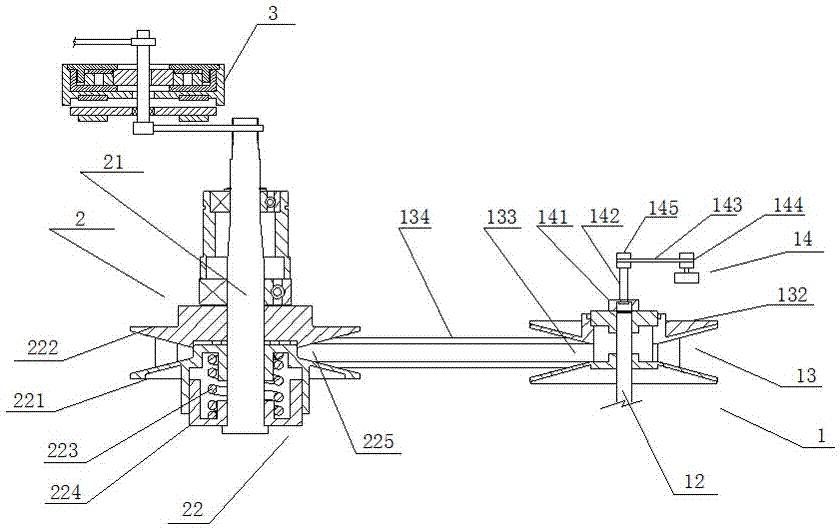

[0031] Such as Figure 1~Figure 7 As shown, the split crawler vehicle of the present invention includes a drive system 11, a crawler wheel 4, a support frame 5, a pedal and an operating rod, the pedal is arranged on the upper part of the support frame 5, and the drive system 11 is fixed on the middle part of the support frame 5 , the drive system 11 includes two symmetrical output shafts 111, the track wheels 4 are symmetrically suspended on both sides of the support frame 5, and the track wheels 4 include the active system 1, the driven system 2, the reversing system 3, the outer crawler belt 6, positioning device 14 and driving wheel 7, the output shaft 111 is connected with the active system 1 and drives the active system to rotate, and the active system 1 is connected with the driven system 2 through a belt and drives the driven system 2 to connect, so The active system 1 is provided with a positioning device 14 for adjusting the rotating speed of the active system 1, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com