A kind of high temperature resistant multi-layer solar energy selective absorption coating and preparation method thereof

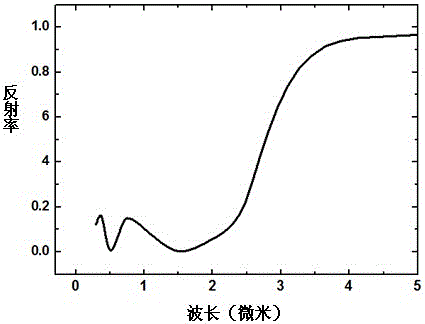

An absorption coating and selective technology, which is applied in the field of solar energy utilization, can solve the problems of increasing the manufacturing process and process of heat collector tubes, low productivity and high cost, and achieves the effects of good spectral selective absorption performance, improved life, and high absorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

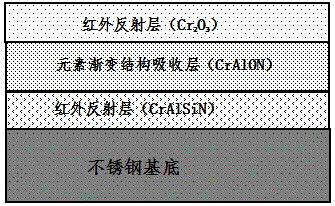

[0025] This embodiment provides a high temperature resistant multilayer solar selective absorbing coating, the absorbing coating is composed of three-layer structure, the top layer is Cr 2 o 3 The anti-reflection layer, the middle layer is a CrAlON absorbing layer with a gradient structure of oxygen content, and the bottom layer is a CrAlSiN infrared reflective layer; wherein, the composition of the absorbing layer CrAlON is as follows: Cr: 35.8 at.%, Al: 16.3 at.%, O: 13.9 at. %, N: 34 at.%; the composition of the infrared reflective layer CrAlSiN is as follows: Cr: 15.2 at.%, Al: 37.8 at.%, Si: 9 at.%, N: 38 at.%.

[0026] The preparation method of the above-mentioned high-temperature resistant multi-layer solar selective absorbing coating comprises the following steps:

[0027] S1. After glow cleaning, control the temperature of the stainless steel substrate at 300°C, close the Ar gas flow valve, and open the N 2 Flow valve, control the air pressure in the coating chamber...

Embodiment 2

[0035] This embodiment provides a high temperature resistant multilayer solar selective absorbing coating, the absorbing coating is composed of three-layer structure, the top layer is Cr 2 o 3 The anti-reflection layer, the middle layer is a CrAlON absorbing layer with a gradient structure of oxygen content, and the bottom layer is a CrAlSiN infrared reflective layer; wherein, the composition of the absorbing layer CrAlON is as follows: Cr: 30.2 at.%, Al: 19.7 at.%, O: 17.7 at. %, N: 32.4 at.%; the composition of the infrared reflective layer CrAlSiN is as follows: Cr: 13.8 at.%, Al: 40 at.%, Si: 6.4 at.%, N: 39.8 at.%.

[0036] The preparation method of the above-mentioned high-temperature resistant multi-layer solar selective absorbing coating comprises the following steps:

[0037] S1. After glow cleaning, control the temperature of the stainless steel substrate at 300°C, close the Ar gas flow valve, and open the N 2 Flow valve, control the air pressure in the coating cha...

Embodiment 3

[0044] This embodiment provides a high temperature resistant multilayer solar selective absorbing coating, the absorbing coating is composed of three-layer structure, the top layer is Cr 2 o 3 The anti-reflection layer, the middle layer is a CrAlON absorbing layer with a gradient structure of oxygen content, and the bottom layer is a CrAlSiN infrared reflective layer; wherein, the composition of the absorbing layer CrAlON is as follows: Cr: 33 at.%, Al: 15 at.%, O: 28 at. %, N: 24 at.%; the composition of the infrared reflective layer CrAlSiN is as follows: Cr: 18.9 at.%, Al: 34.1 at.%, Si: 9.2 at.%, N: 37.8 at.%.

[0045] The preparation method of the above-mentioned high-temperature resistant multi-layer solar selective absorbing coating comprises the following steps:

[0046] S1. After glow cleaning, control the temperature of the stainless steel substrate at 300°C, close the Ar gas flow valve, and open the N 2 Flow valve, control the air pressure in the coating chamber a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com