A rolling rotor compressor

A rolling rotor type, compressor technology, applied in the direction of rotary piston type machinery, machine/engine, rotary piston type pump, etc., can solve the problems of roller wear, reduced compressor reliability, high contact stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

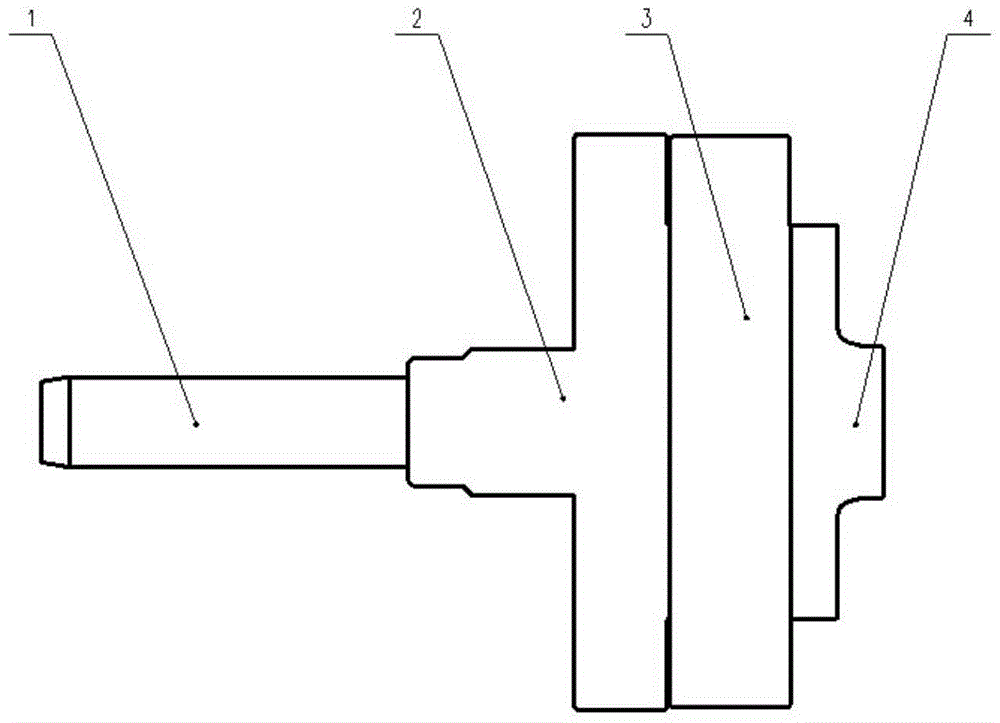

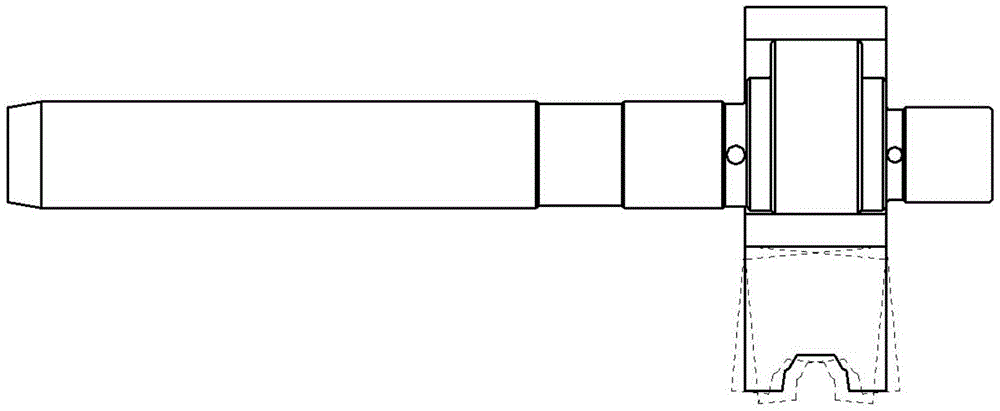

[0024] The following embodiments of the present invention are applicable to rolling rotor compressors having one or more working chambers. figure 1 The structure of a pump body (working chamber) of a rolling rotor compressor is shown in . For ease of illustration, Figure 1-Figure 6 The pump body in the table is expressed horizontally, but in practice, the pump body is usually placed vertically. Such as figure 1 As shown, the pump body generally includes a crankshaft 1 , an upper flange 2 , a cylinder 3 , and a lower flange 4 , wherein the cylinder 3 is arranged between the upper flange 1 and the lower flange 2 .

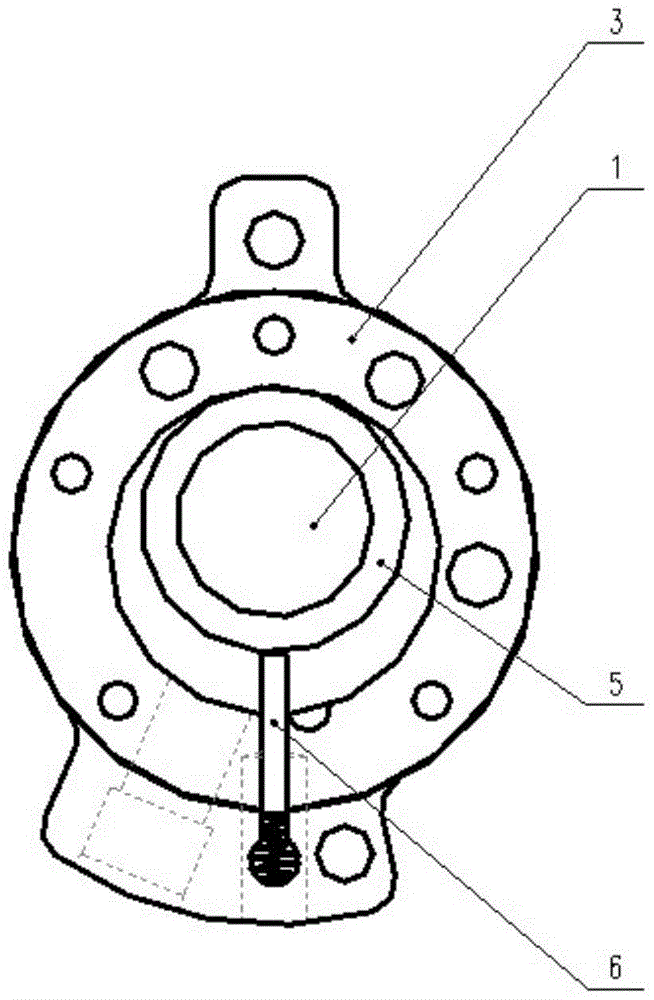

[0025] In the existing technology, such as figure 2 The pump body of the rolling rotor compresso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com