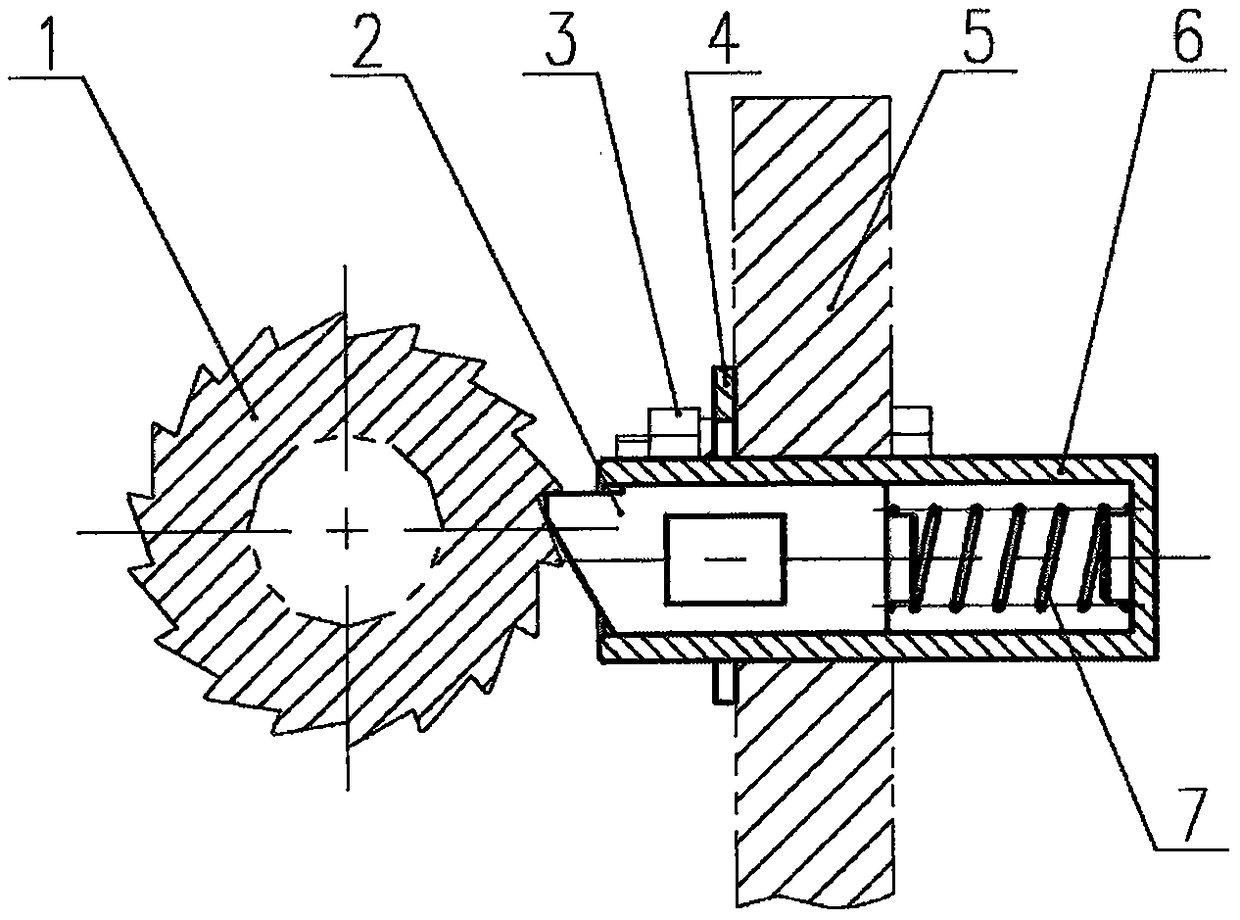

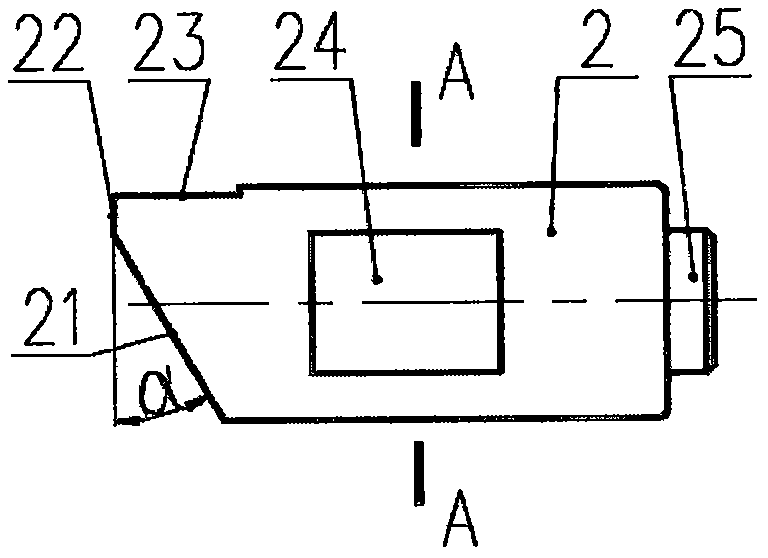

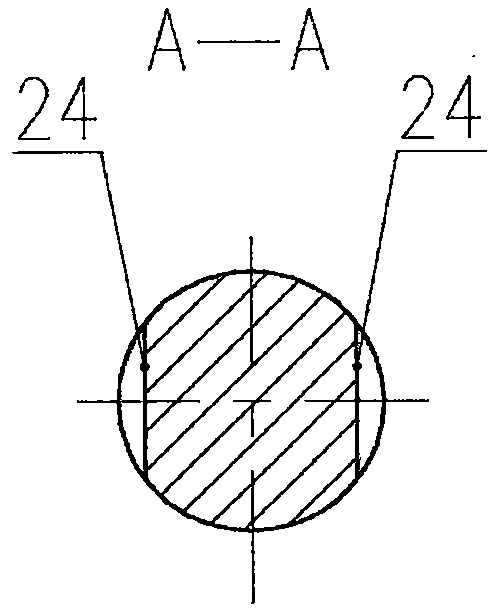

A lever assembly of a ratchet compensation device for an industrial brake

A compensating device and brake technology, applied in the direction of slack adjusters, etc., can solve the problems of heavy brake maintenance workload, fast wear of pawls, hidden dangers of personal and equipment safety, etc., to enhance environmental adaptability, reduce local contact stress, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: When the present invention is used in an electrohydraulic drum brake, the lever assembly is mounted on a suitable position of the brake lever plate 5, and when the electrohydraulic pusher pushes the brake lever plate 5 to rotate, the lever 2 can be toggled and The ratchet 1 connected to the brake pull rod rotates to realize automatic compensation of brake lining wear.

Embodiment 2

[0031] Embodiment 2: When the present invention is used in an electrohydraulic disc brake, the shift lever assembly is mounted on a proper position of the brake lever plate 5, and its compensation principle is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com