Composite piston pin for internal combustion engine

A technology of piston pin and internal combustion engine, applied in the direction of piston, cylindrical piston, plunger, etc., can solve the problems of unclear support effect and effectiveness, surge of tensile stress in the transition area on both sides, large intermediate rigidity, etc., and achieve overall weight reduction. Significant effect, reduce inertial force, reduce wear and impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

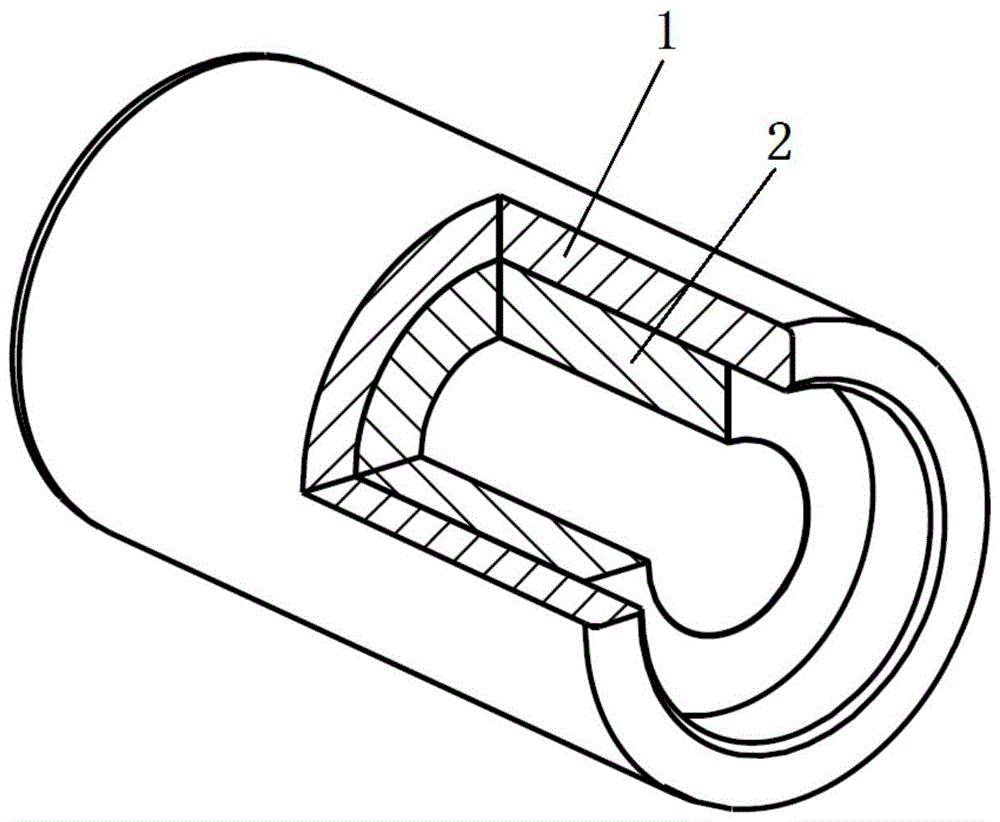

[0024] like figure 1 As shown, the composite piston pin includes a piston pin matrix 1 and a piston pin filling body 2. Wherein the filling body 2 is made of lightweight materials such as aluminum alloy.

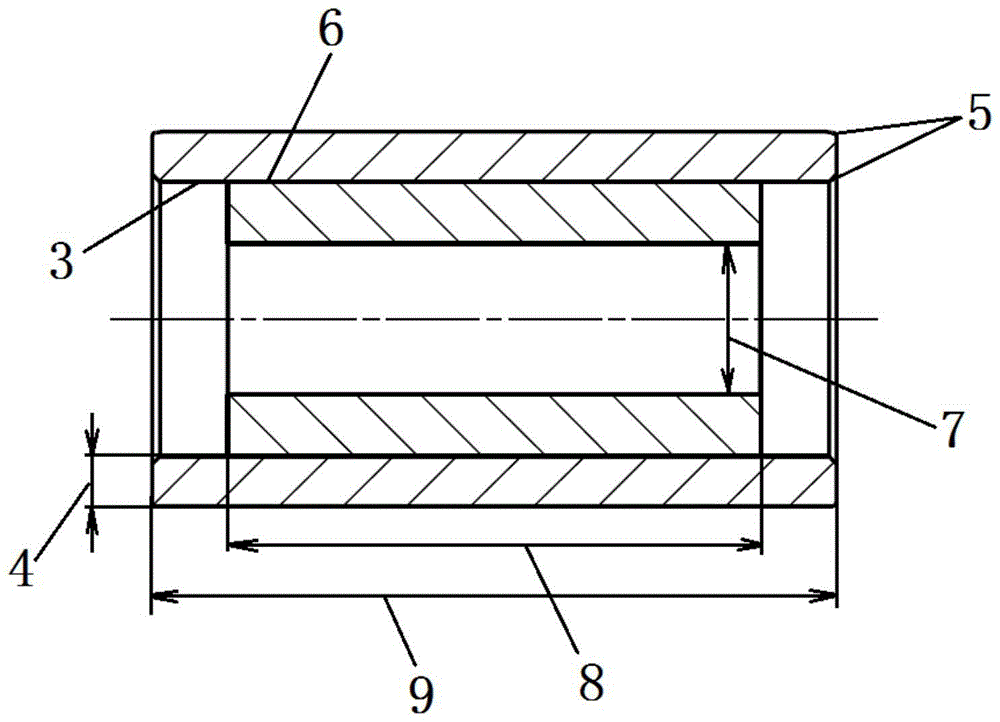

[0025] like figure 2 As shown, the piston pin base 1 is hollow, the inner surface 3 is straight, the middle wall thickness 4 is 2-25mm, and the wall thickness is 10-35% of the outer diameter of the cylinder of the piston pin base. Corner or rounding5. An aluminum rod is placed in the inner hole of the matrix 2, and the outer surface 6 forms an interference fit with the inner surface 3 of the matrix by forging. The filling body can be hollow or solid, and its inner hole can be obtained by machining, and the radius 7 of the hole in the filling body is 0-10 mm. The length 8 of the filling body is smaller than the length 9 of the base body.

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com