A battery automatic heat press machine

A technology of hot press and electric core, which is applied in the direction of assembling batteries, circuits, electrical components, etc., can solve the problems of high cost, affecting product quality, and low efficiency, and achieve high production efficiency, stable quality, and reduced manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in detail below in conjunction with the accompanying drawings.

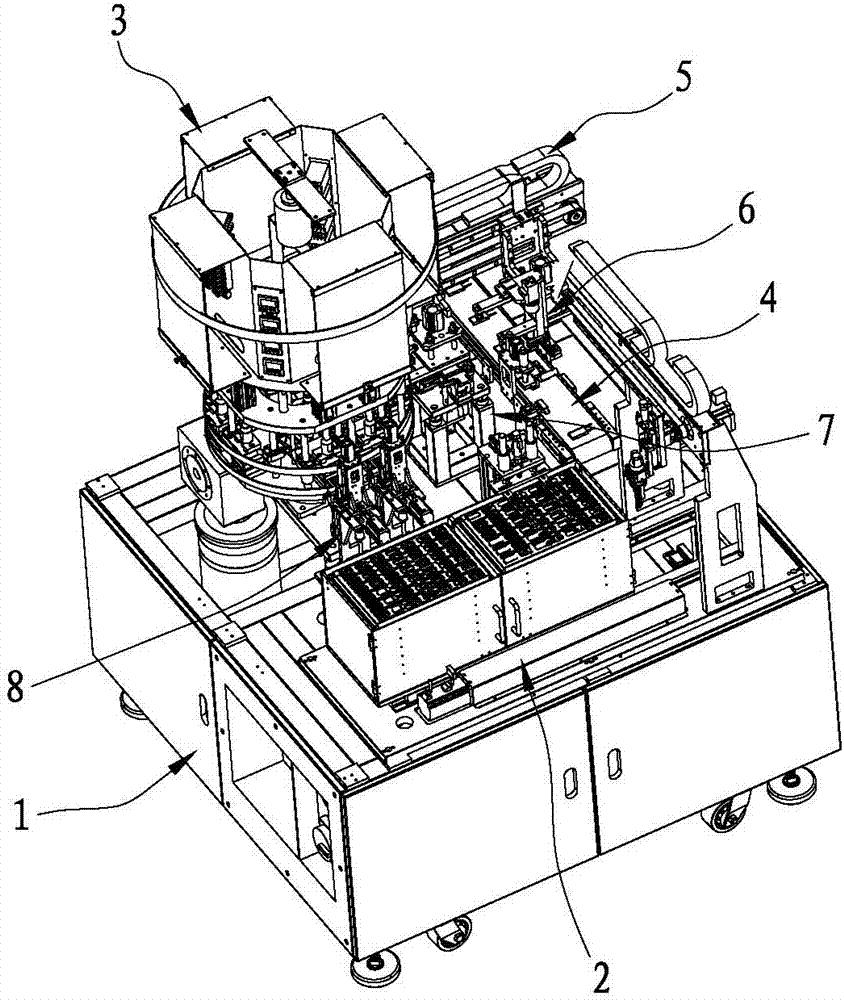

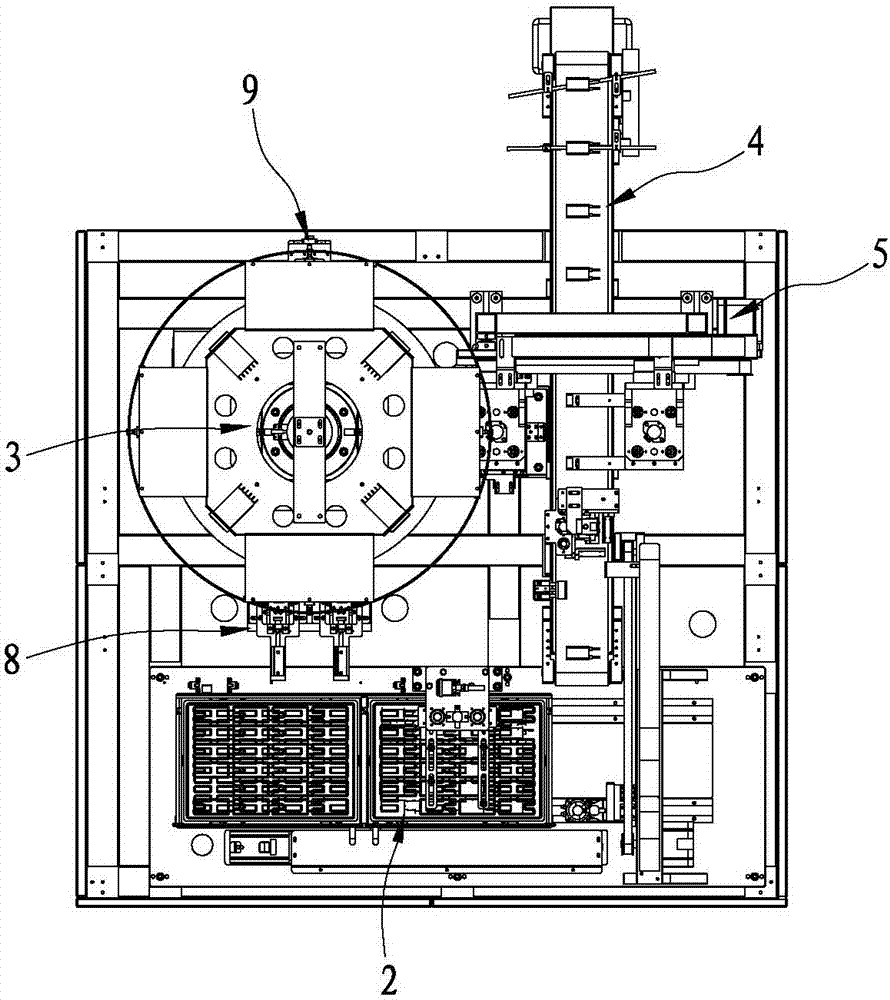

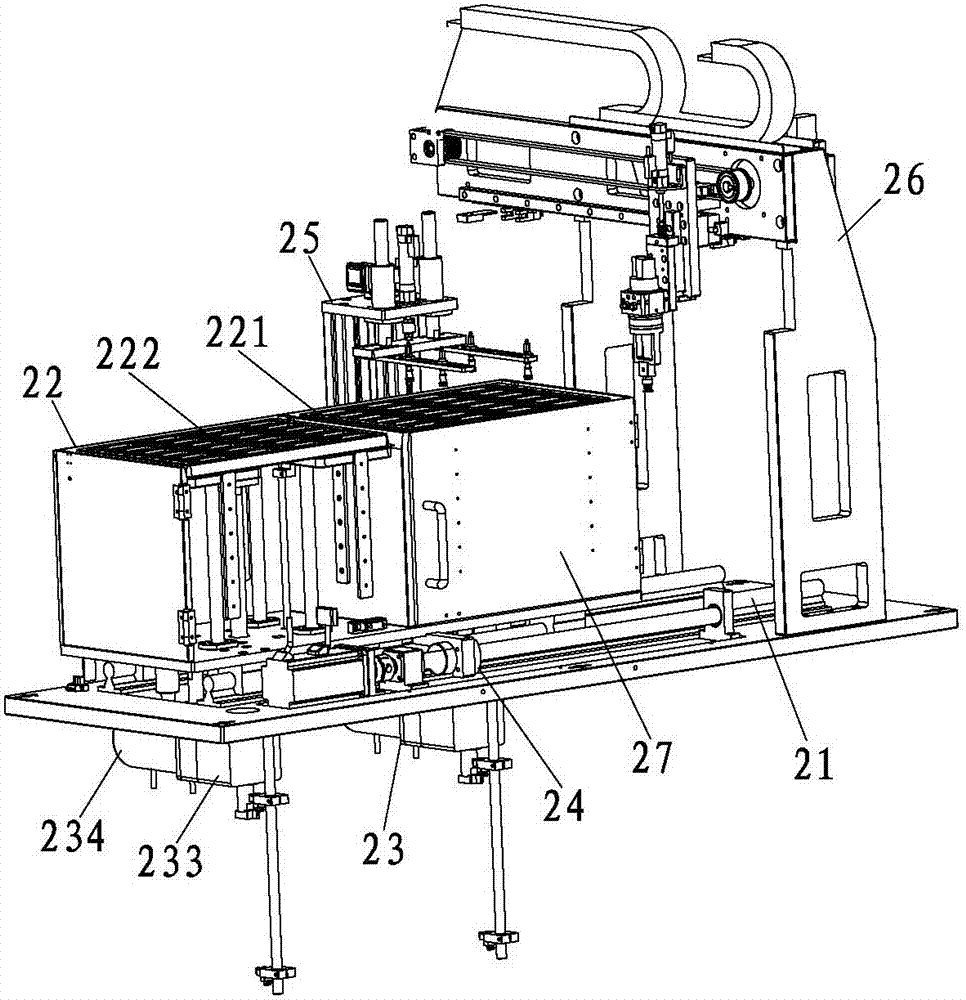

[0061] see Figure 1 to Figure 11 , an automatic heat press machine for battery cells, including a base 1, the base 1 can be an independent piece, and can also be installed on other equipment, the base 1 is provided with a heat press device 3, and also includes: a feeding device 2, set On the side of the hot pressing device 3; the positioning device 4 receives and positions the electric core of the feeding device 2; the material transfer device 5 is used to send the electric core to the hot pressing device 3 for hot pressing; the control device is used to control The hot pressing device 3 , the feeding device 2 , the positioning device 4 and the material moving device 5 . The control device includes a PCB board and a PLC programmable control chip arranged on the PCB board. The working principle of the hot press is: when working, the electric core is first sent into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com