Vertical hole multi-face corrugated packing and structured packing

A technology of corrugated packing and structured packing, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of fixed contact time and short residence time, large gas phase resistance, and low mass transfer effect and other problems, to achieve the effects of large flux, reduced wall flow, and increased gas-liquid mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be described below in conjunction with the accompanying drawings, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

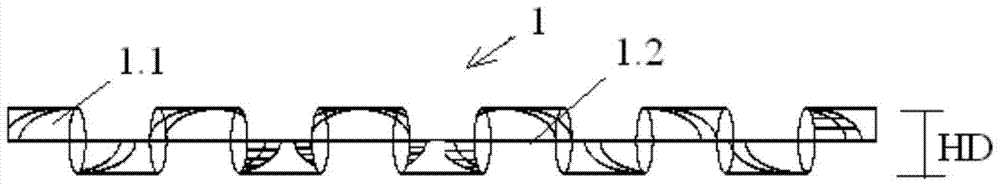

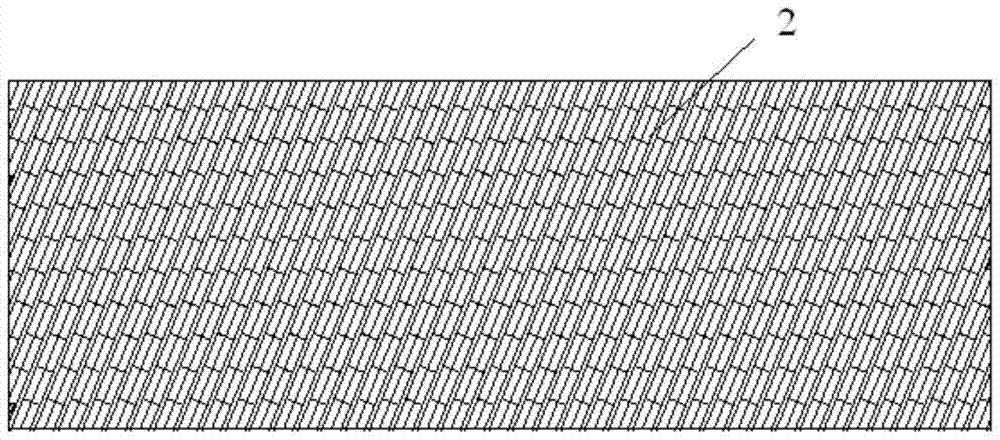

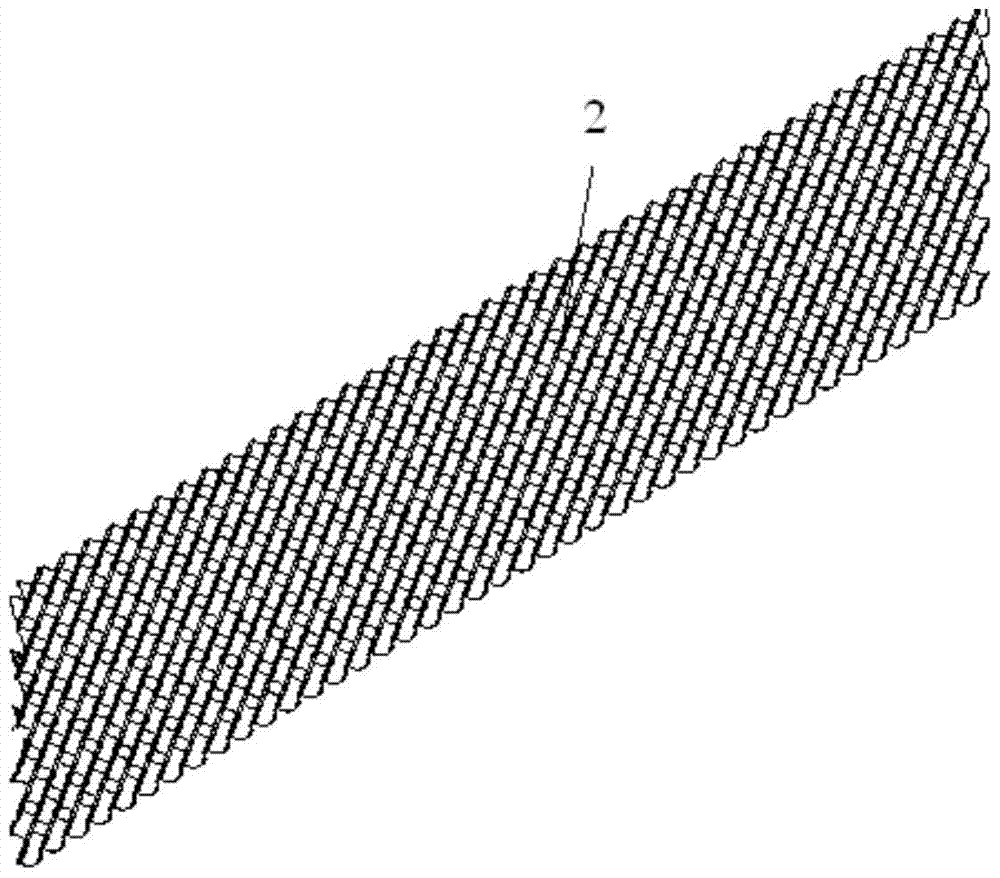

[0018] refer to Figure 1-4 As shown: vertical hole multifaceted corrugated packing of the present invention, the vertical hole mesh plate 1 is composed of a bottom plate 1.1 and a channel 1.2, and the described channel 1.2 is evenly spaced up and down with the bottom plate 1.1 as the axis; the vertical hole mesh plate 1 has a plate thickness of 0.1 -0.5 mm, the height is 10-500 mm, the opening rate of the upper and lower areas is 35%-95%, the height of the upper area is 1-9 mm, the height of the lower area is 1-9 mm, and the opening rate of the central main area is 70%-95%; the corrugated sheet 2 processed by the vertical hole screen 1 has a peak height of 1-9 mm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com