Preparation method of surface modified pine needle loaded lanthanum hydroxide phosphorus adsorbent

A technology of lanthanum hydroxide and phosphorus adsorbents, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of difficult separation, difficult recovery, and easy aggregation of metal adsorbent particles, and achieve Facilitates loading and stabilization, improves soil conditions, reduces total organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

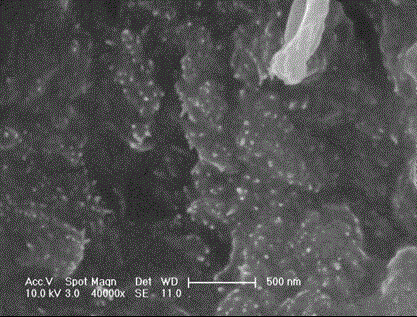

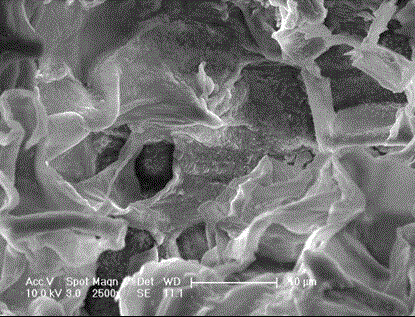

[0022] The collected pine needles were washed 5 times with warm water, dried at 80°C for 12 hours, crushed, ground and sieved, and 100 grams of crushed pine needles with a length ranging from 1 to 2.5 mm were placed in 500 mL (V 1MNaOH :V 异丙醇 =1:1) Immerse in alkali-alcohol solution for 24h. Wash with water until the test result of total organic matter in the supernatant is constant, and dry at 80°C for 12 hours. Weigh 20g of the treated pine needles, put into 200mL0.1mol / LLa(NO 3 ) 3 solution, then dropwise add ammonia solution with a mass fraction of 28% under stirring conditions, adjust the pH value of the solution between 8 and 9, and let it stand for 12 hours. During this period, stir for 5 minutes every 3 hours, and the stirring speed is 5 revolutions. / min, the washing-draining cycle is repeated 5 times, and then dried at 80°C for 12 hours. The scanning electron microscope (SEM) images of the prepared adsorbents are shown in figure 1 , figure 2 .

Embodiment 2

[0024] The collected pine needles were washed 5 times with warm water, dried at 60°C for 12 hours, crushed, ground and sieved, and 200 grams of crushed pine needles with a length ranging from 1 to 2.5 mm were placed in 1000 mL (V 1MNaOH :V 异丙醇 =1:1) Immerse in alkali-alcohol solution for 24h. Wash with water until the test result of total organic matter in the supernatant becomes constant, and dry at 60°C for 12 hours. Weigh 40g of treated pine needles, put into 400mL0.1mol / LLa(NO 3 ) 3 solution, then dropwise add ammonia solution with a mass fraction of 28% under stirring conditions, adjust the pH value of the solution between 8 and 9, and let it stand for 12 hours. During this period, stir for 5 minutes every 3 hours, and the stirring speed is 5 revolutions. / min, the washing-draining cycle is repeated 5 times, and then dried at 80°C for 12 hours.

Embodiment 3

[0026] The collected pine needles were washed 5 times with warm water, dried at 100°C for 12 hours, crushed, ground and sieved, and 200 grams of crushed pine needles with a length ranging from 1 to 2.5 mm were placed in 1000 mL (V 1MNaOH :V 异丙醇 =1:1) Immerse in alkali-alcohol solution for 24h. Wash with water until the test result of total organic matter in the supernatant becomes constant, and dry at 100°C for 12 hours. Weigh 20g of the treated pine needles, put into 200mL0.1mol / LLa(NO 3 ) 3 solution, then dropwise add ammonia solution with a mass fraction of 28% under stirring conditions, adjust the pH value of the solution between 8 and 9, and let it stand for 12 hours. During this period, stir for 5 minutes every 3 hours, and the stirring speed is 5 revolutions. / min, the washing-draining cycle is repeated 5 times, and then dried at 80°C for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com