Medical adhesive plaster coating device and medical adhesive plaster coating method

A coating device and adhesive plaster technology, which is applied in the field of preparation of medical adhesive plaster, can solve problems such as high energy consumption, high risk, and low efficiency, and achieve the effects of eliminating environmental pollution, reducing energy consumption, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the characteristics and advantages of the present invention clearer, the following description will be made in conjunction with specific embodiments.

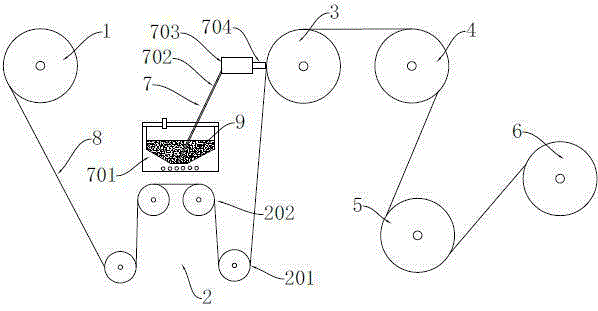

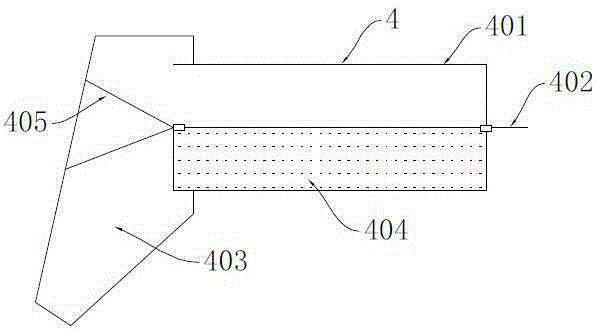

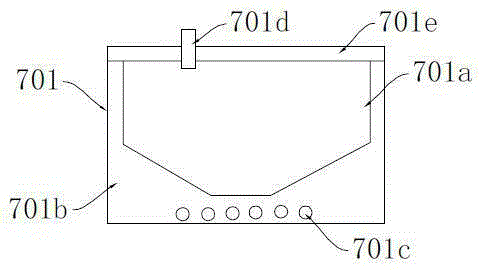

[0025] like Figure 1~Figure 4 Shown, a kind of medical adhesive plaster coating device comprises unwinding roll 1, guide roll 2, coating roll 3, cooling roll 4, embossing roll 5, winding roll 6, coating device 7, base cloth 8, containing The hot-melt pressure-sensitive adhesive 9 of zinc oxide powder, the base cloth 8 is fixed on the unwinding roller 1, and the end of the base cloth 8 passes through the tensioned guide roller 2, coating roller 3, cooling roller 4 and molding roller in sequence 5, the end of the base cloth 8 is fixed on the winding roller 6, the outer surface of the coating roller 3 is provided with a coating device 7, the guide roller 2, the molding roller 5 and the winding roller 6 are located at the unwinding roller 1, coating Below the roller 3 and the cooling roller 4, the unwindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com