Dry-method lump coal sorting device

A sorting device and dry method technology, applied in sorting and other directions, can solve the problems of dust removal, processing capacity, and energy consumption that are not well applied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

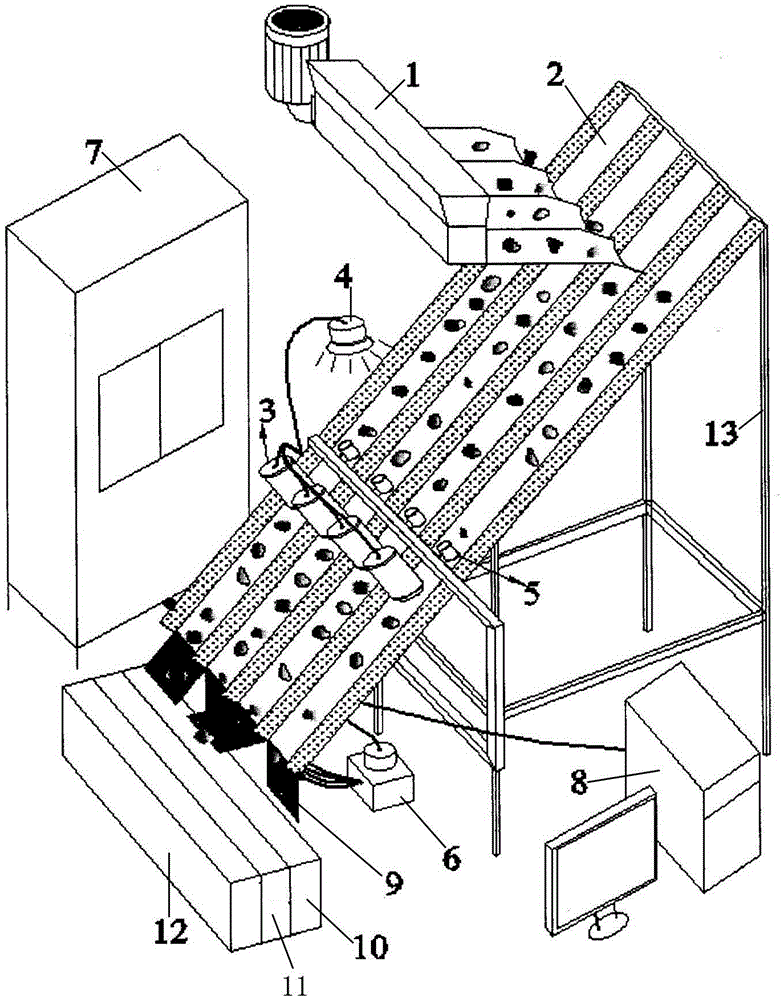

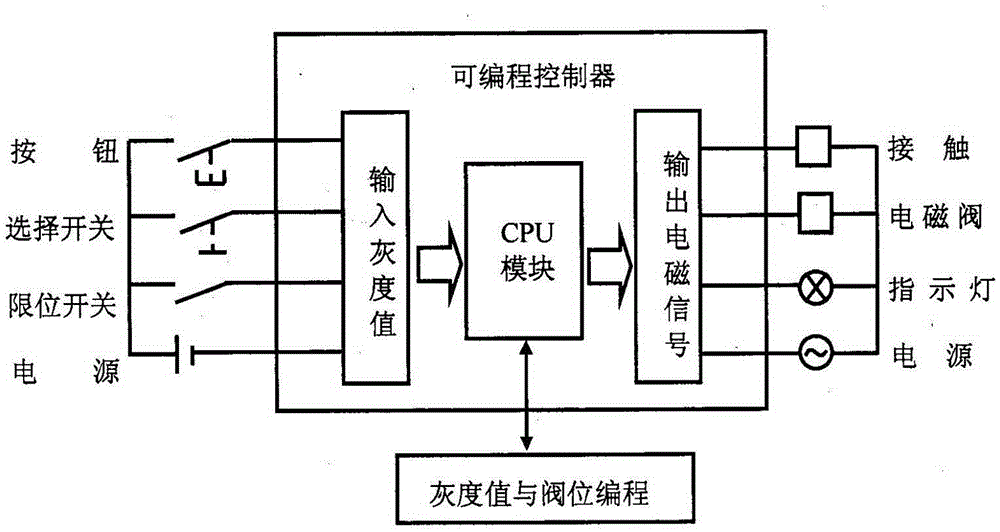

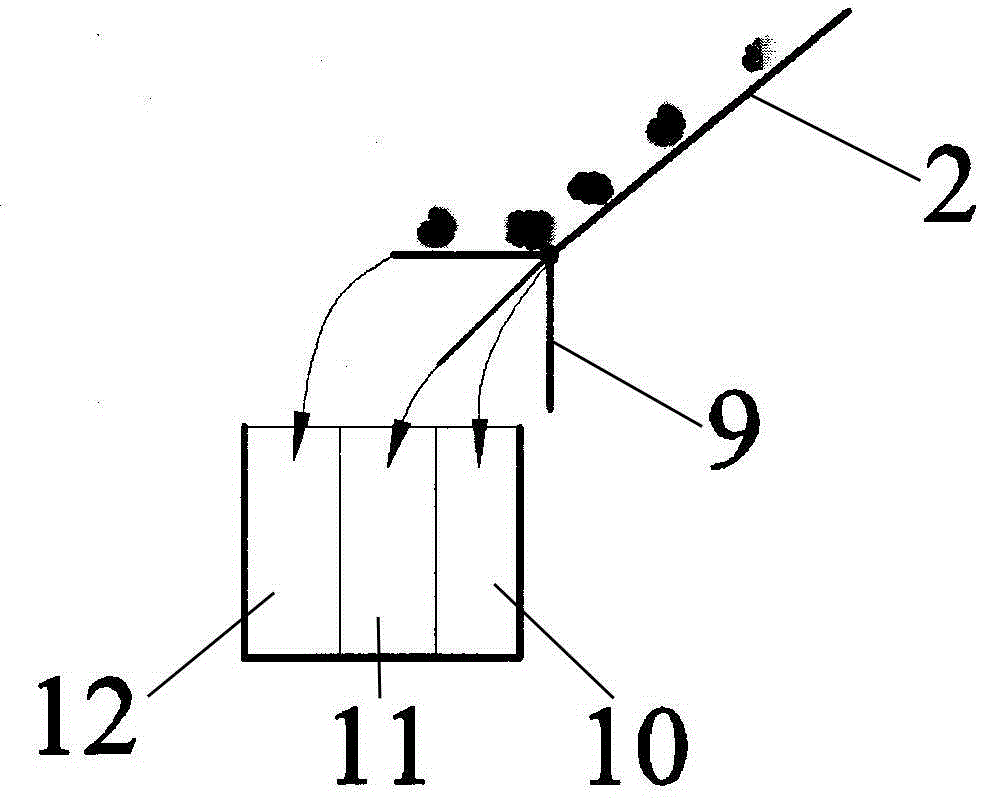

[0020] Such as figure 1 As shown, the dry lump coal separation device of the present invention includes a lumpy raw coal slideway 2 provided with a plurality of chutes installed on the support 13 in an oblique manner, and the vibration queue installed in the middle and upper part of the lumpy raw coal slideway 2 Feeding device 1, the vibration queuing feeding device 1 is provided with a quantity equal to the number of chutes of the block raw coal slideway and one-to-one corresponding discharge ports, in each chute of the block raw coal slideway 2 The lower part is respectively provided with a CMOS industrial camera 3 and a lens dust remover 5 connected to the image post-processing device 8 through a data line, and an illumination device 4 is arranged above the installation position of the CMOS industrial camera 3. The outlets of the two chutes are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com