Horizontal NC cold bending machine for large size components and its NC cold bending method

A large-scale, cold-bending machine technology, applied in the direction of feeding device, positioning device, storage device, etc., to achieve the effect of easy standardization, simplified forming equipment system, and reasonable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

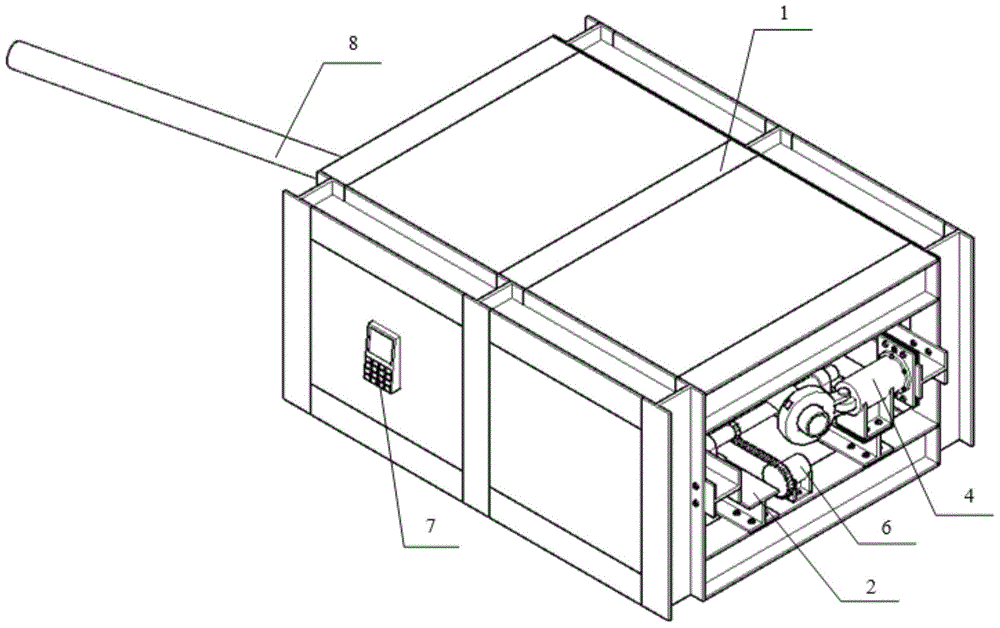

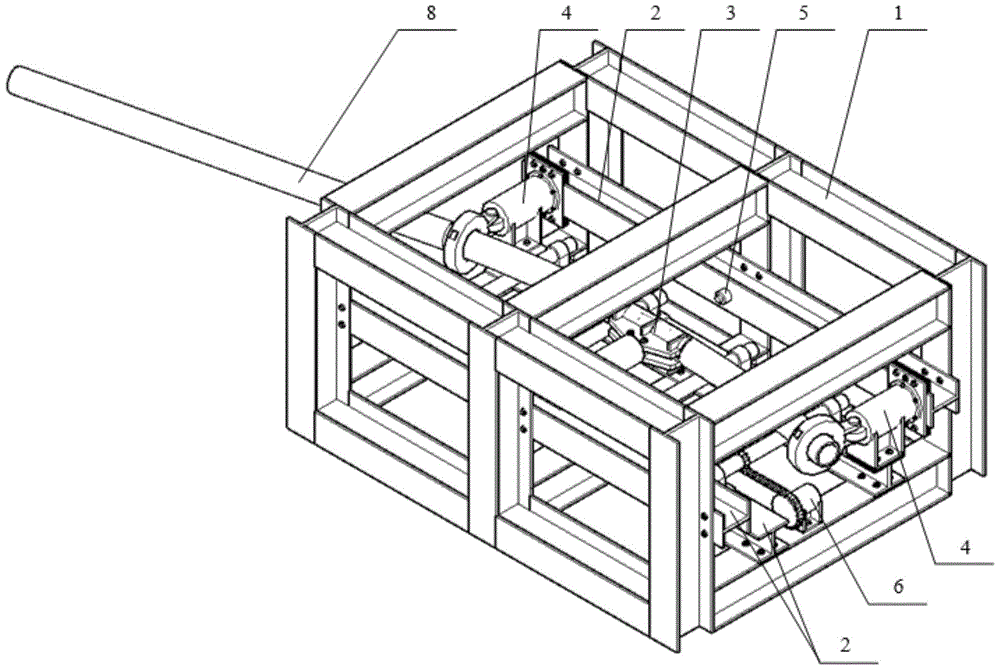

[0028] see figure 1 with figure 2 , the outside of the horizontal CNC cold bending machine for large-size components of the present invention is a forming tire frame 1, and the forming tire frame 1 is a rectangular frame structure. A mounting beam 2 , a loading device 3 , a supporting device 4 , a displacement measuring device 5 and a feeding device 6 are installed inside the formed tire frame 1 . A numerical control device 7 is installed on the outer side of the tire frame 1 to realize the control of the forming process. The member 8 to be bent extends into the inside of the formed tire frame 1 from the rear of the formed tire frame 1 for cold bending and moves forward.

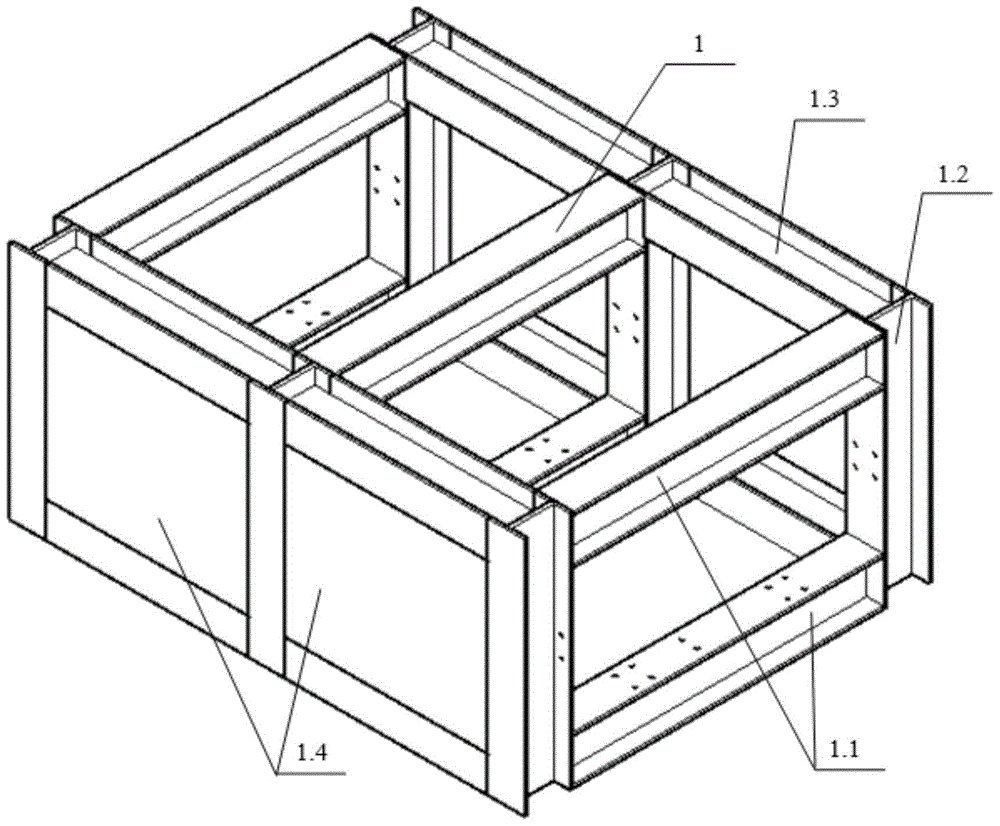

[0029] see image 3 The formed tire frame 1 is composed of three rectangular plane frames composed of frame beams 1.1 horizontally arranged horizontally on the left and right, vertical columns 1.2 arranged vertically up and down, and connecting beams 1.3 horizontally arranged front and rear. The front side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com