Wedge block bidirectional force increasing type flying shear machine

A flying shear and force-increasing technology, applied in the field of flying shears, can solve the problems of bulky equipment, inability to meet production, and low cutting precision, and achieve the effects of energy saving, simple structure, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

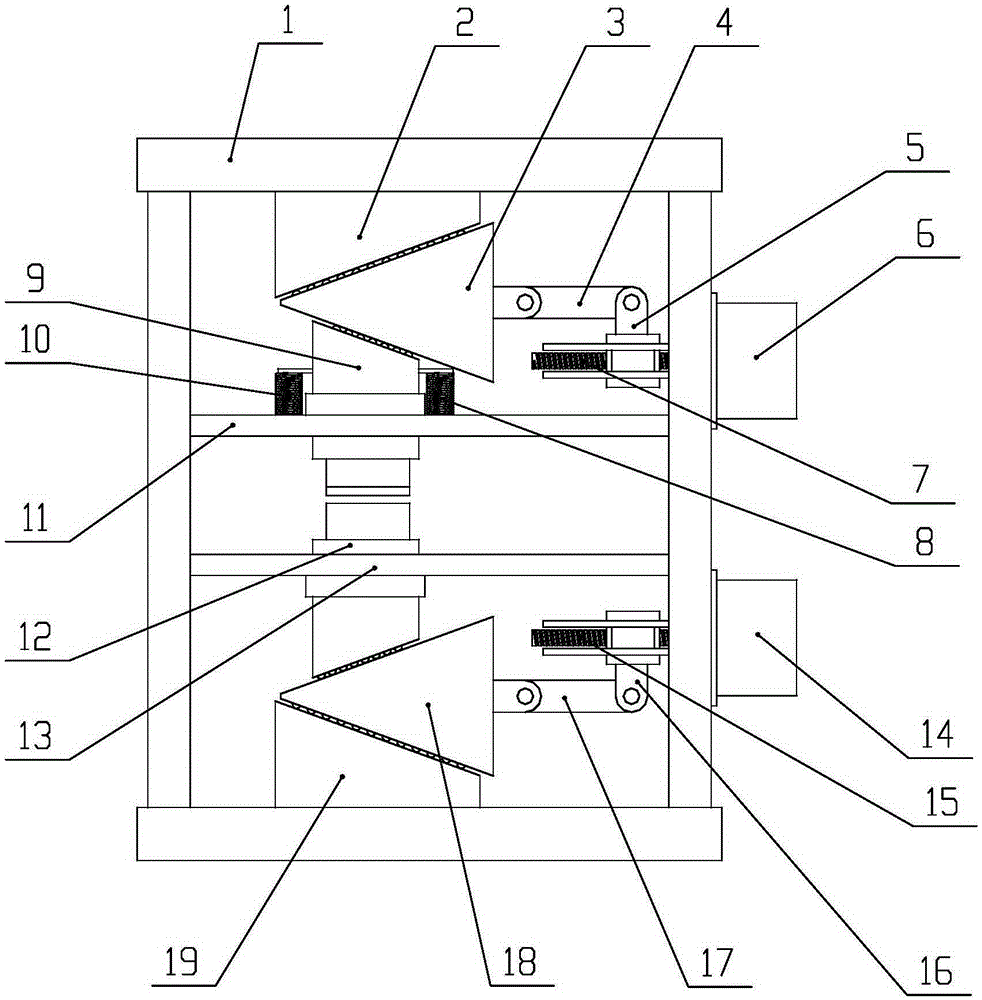

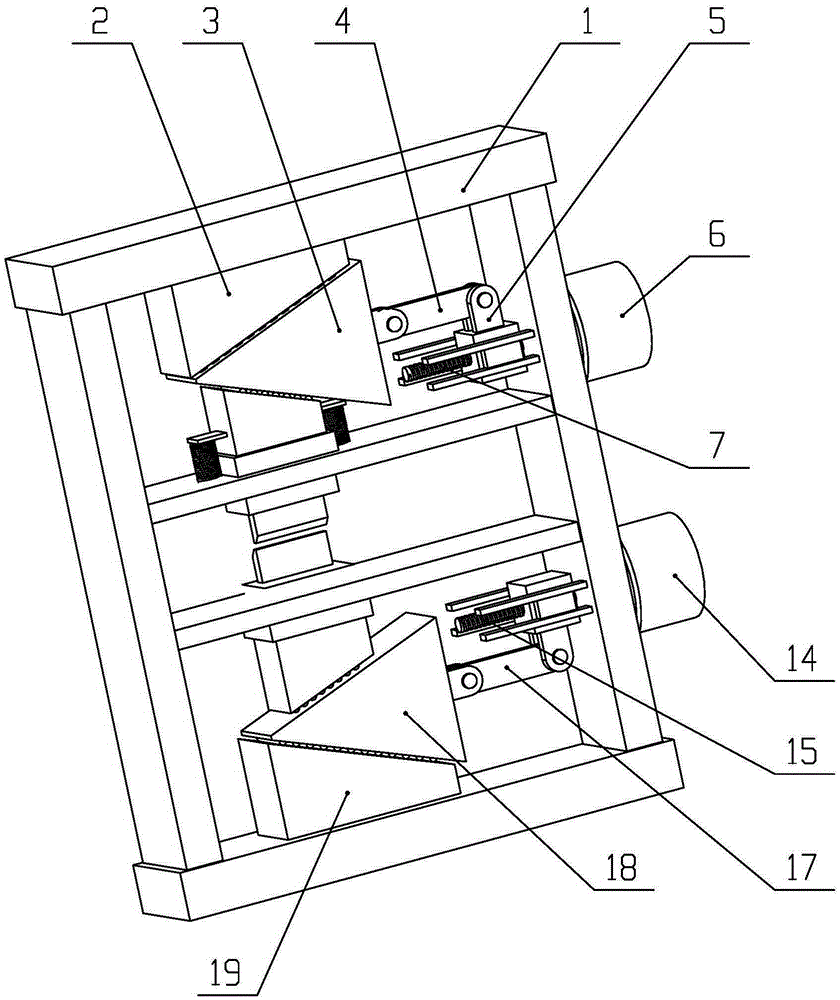

[0016] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode and in conjunction with the accompanying drawings.

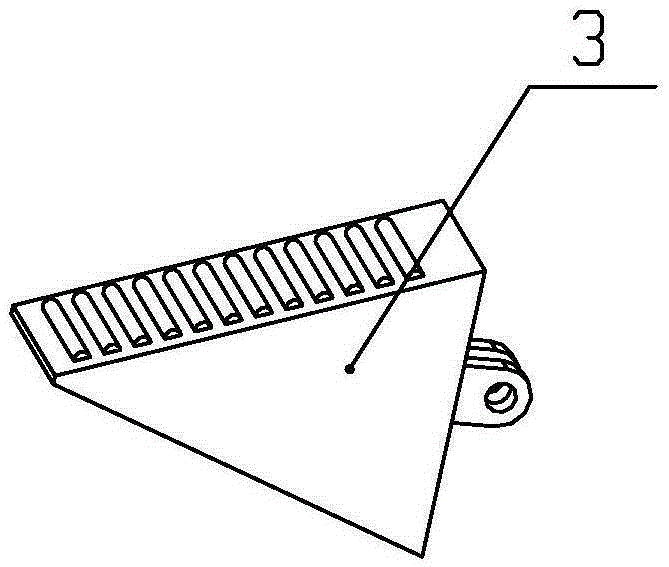

[0017] A wedge bidirectional force-increasing flying shear, designed with a symmetrical structure up and down, consisting of a frame 1, a first wedge 2, a second wedge 3, a first connecting rod 4, a first slider 5, and a first motor 6. The first screw 7, the first spring 8, the first scissors module 9, the second spring 10, the upper guide beam 11, the second scissors module 12, the lower guide beam 13, the second motor 14, the second screw 15 , the second slider 16, the second connecting rod 17, the third wedge 18 and the fourth wedge 19, the frame 1 is fixedly installed on the ground, and the first wedge 2 and the fourth wedge 19 are fixedly installed on the The upper and lower parts of the frame 1, the upper and lower wedge surfaces of the second wedge 3 are respectively...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap