An automatic solvent replenishment system for a table tennis production line

A technology for supplementing systems and production lines, applied in household components, household appliances, other household appliances, etc., can solve the problems of high transportation cost and high cost of table tennis, and achieve the effect of stable solvent speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

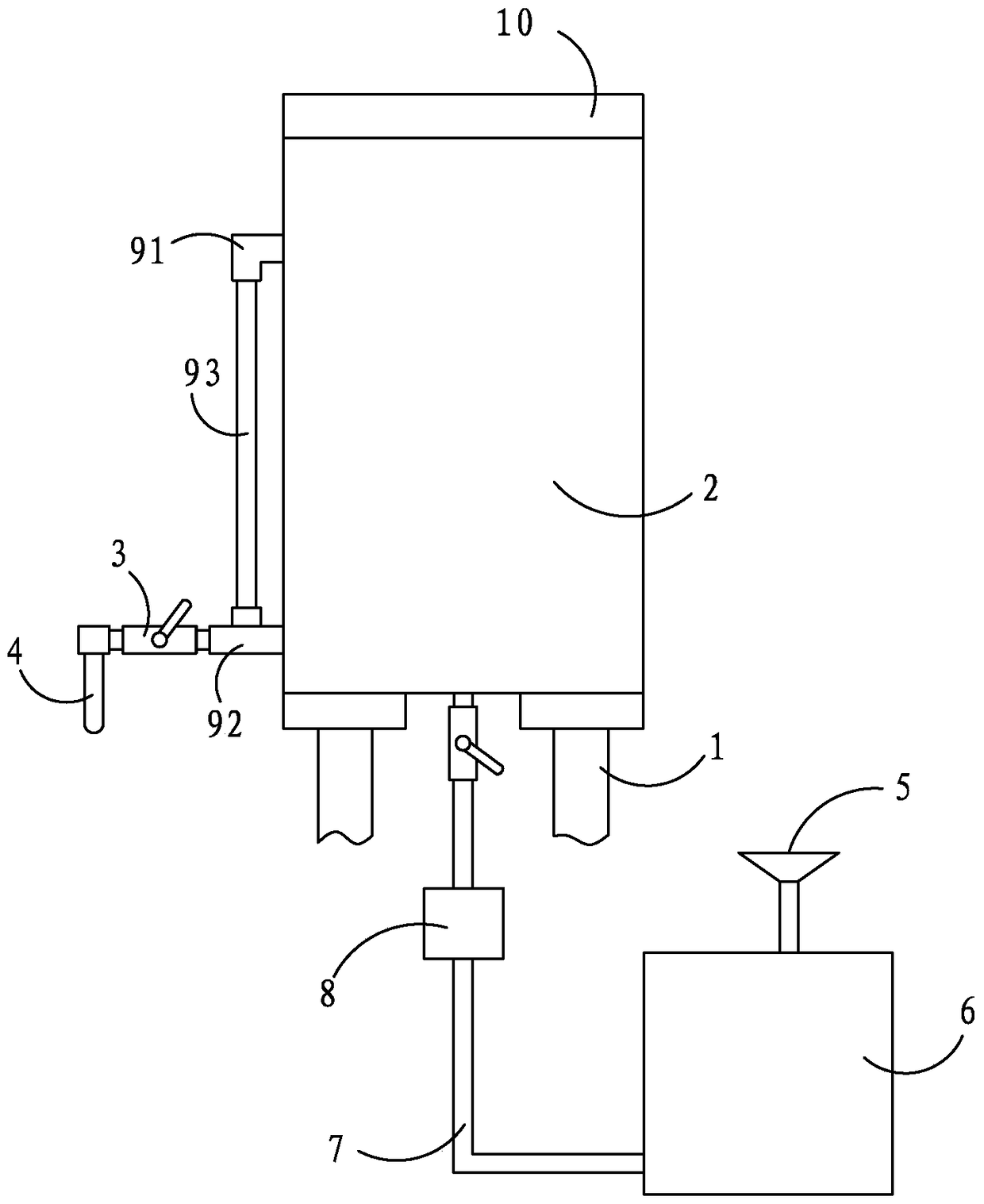

[0014] Embodiment one: see attached figure 1 As shown, a table tennis production line automatic solvent replenishment system, which includes a support 1, a solvent barrel 2 arranged on the support 1, a solvent outlet valve 3 arranged on the side of the lower part of the solvent barrel 2, a solvent outlet 4 and a reflux for collecting overflowing solvent device, the backflow device includes a receiving port 5 for receiving overflowing solvent, a storage tank 6 communicated with the receiving port 5, a return pipeline 7 connecting the bottom of the storage tank 6 and the bottom of the solvent barrel 2, and a solvent pump 8 arranged on the return pipeline 7, The bottom of the solvent bucket 2 is set higher than the top of the storage tank 6 .

[0015] The side wall of the solvent bucket 2 is provided with a liquid level gauge, and the liquid level gauge includes an upper pipe 91 connected to the top of the solvent bucket 2, a lower pipe 92 connected to the bottom of the solvent b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com