Three-dimensional printing platform adjusting method and three-dimensional printer

A three-dimensional printer and three-dimensional printing technology, applied in the field of printing, can solve the problems of high model scrap rate, inability to connect extruded silk, affecting user experience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

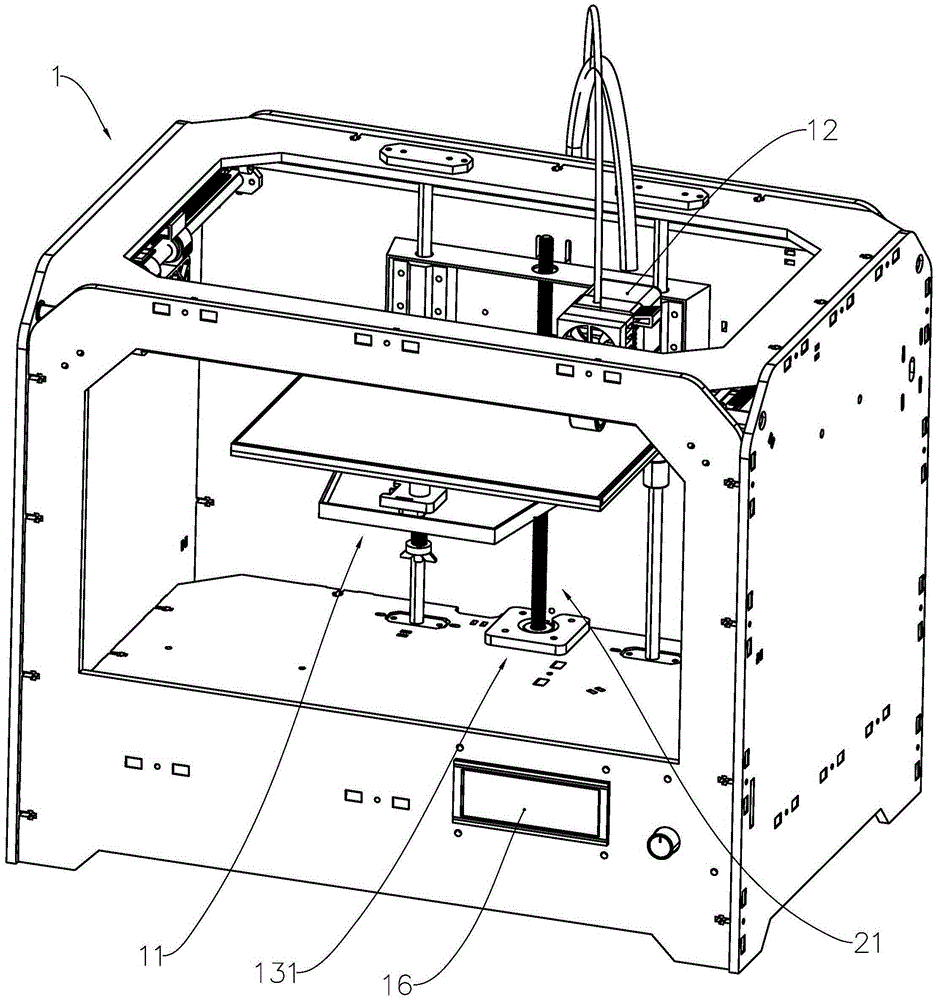

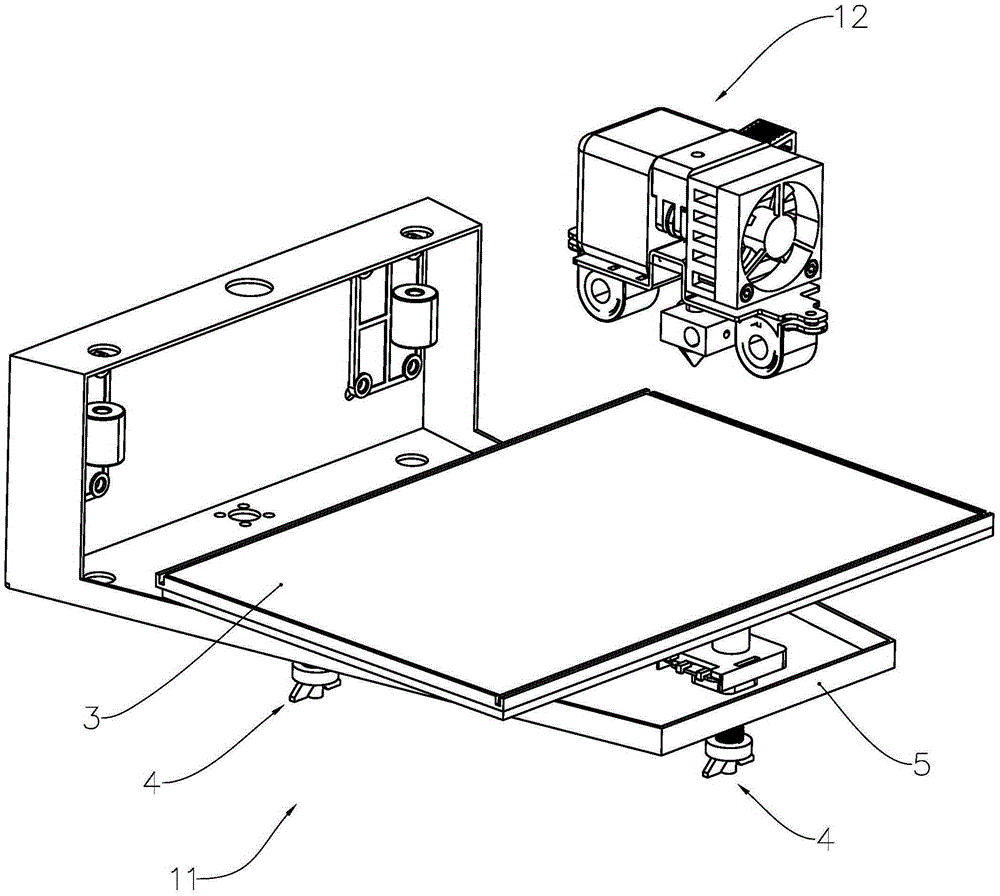

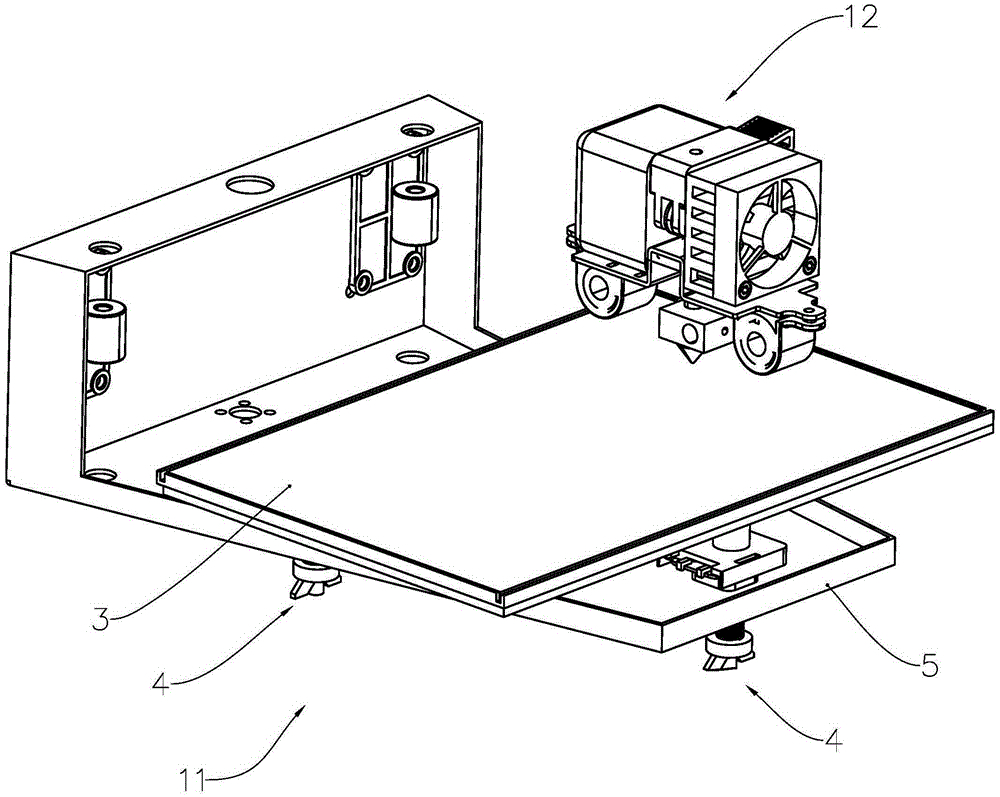

[0041] 3D printer embodiment:

[0042] refer to figure 1 and combine Figure 8 , figure 1It is a structural diagram of a three-dimensional printer 1. The three-dimensional printer 1 includes a three-dimensional printing platform 11, a print head 12, a Z-axis servo motor 131, a Y-axis servo motor 132, and an X-axis servo motor all installed in a frame (not shown) of the three-dimensional printer. 133, the control unit 14, the pressure sensor assembly 15 and the display unit 16, the screw 21 passes through the three-dimensional printing platform 11, a Z-axis servo motor 131 is connected to the lower end of the screw 21, and guide rods are also arranged on both sides of the screw 21 .

[0043] The print head 12 is installed on the X-axis guide rod, and the X-axis guide rod is connected with the X-axis servo motor 133. Driven by the X-axis servo motor 133, the print head 12 can move along the X-axis, and the X-axis guide rod is also connected with the Y-axis Guide rod (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com