Tracked robot with rapidly disassembled and assembled front and rear swing arms

A front-to-rear swing and crawler-type technology, which is applied to tracked vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of inconvenient installation and disassembly of robots, affecting the mobility of robots, etc., to achieve rapid disassembly, increase application occasions, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

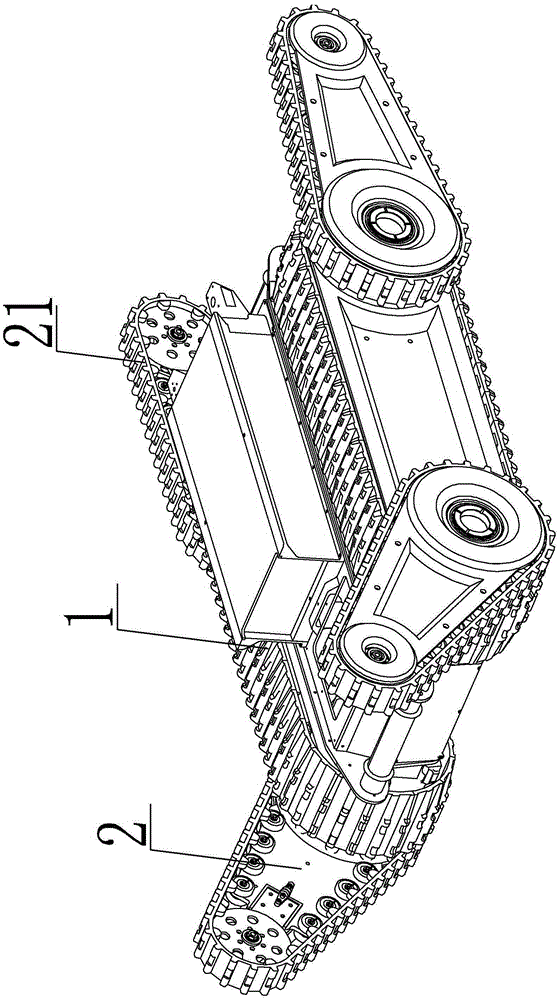

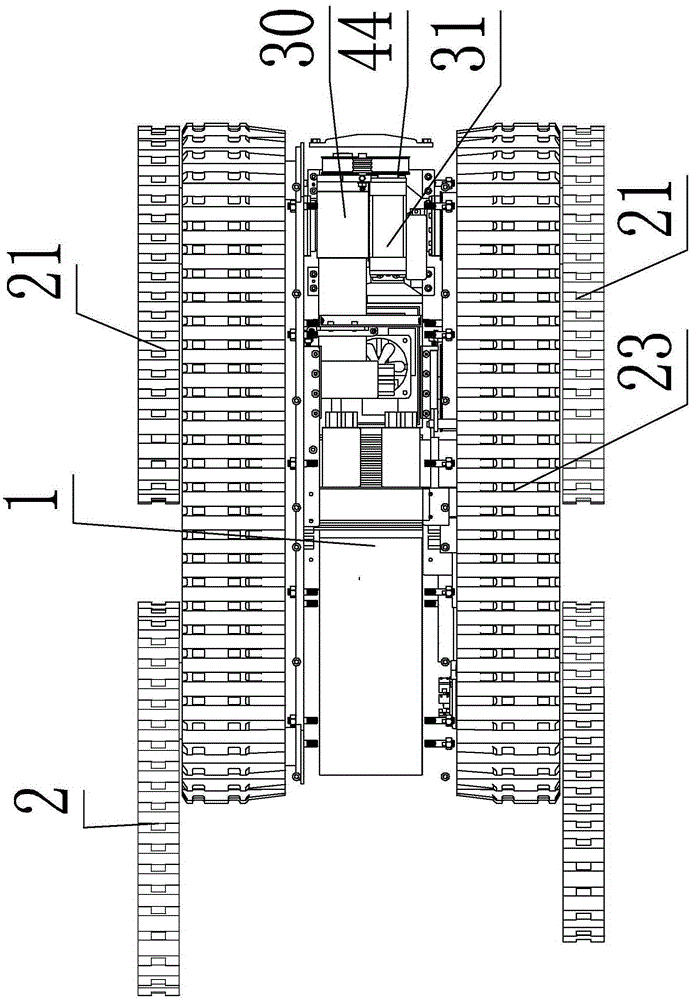

[0011] Specific implementation mode one: combine Figure 1-Figure 15 Describe this embodiment, a crawler robot with quick disassembly and assembly front and rear swing arms described in this embodiment, it includes a crawler body walking robot 1, two front swing arm mechanisms 2 and two rear swing arm mechanisms 21; Body walking robot 1 comprises robot body 24, two walking wheel shafts 9, two walking wheels 10, two drive wheels 22, two main body robot crawlers 23, two main body motors 25, two main body motor reducers 26, two Coaxial clutch pulley 27, two rear shaft spline sleeves 28 and two rear transmission shafts 29, front swing arm mechanism 2 includes forearm motor 3, forearm worm gear assembly 4, front hanging wheel disc 5, forearm connecting wheel 6, The forearm shaft is connected to the flange 7 and the forearm swing body 8; two rear swing arm mechanisms 21 are symmetrically arranged on both sides of the two driving wheels 22 at the rear end of the crawler body walking ...

specific Embodiment approach 2

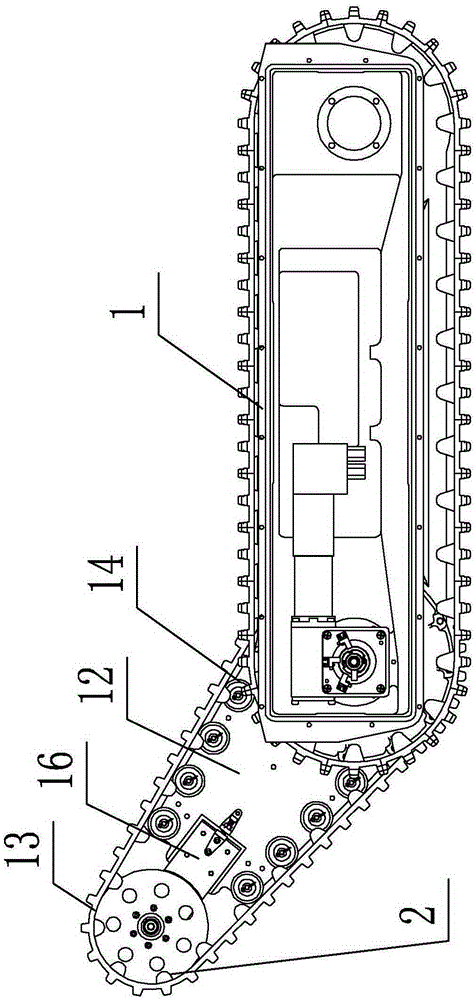

[0012] Specific implementation mode two: combination Figure 1-Figure 5 Describe this embodiment, a crawler robot with quick disassembly and assembly front and rear swing arms described in this embodiment, the forearm swing body 8 includes a forearm fixing plate 12, a forearm track 13, a second forearm wheel connecting plate 16, a forearm First wheel 11, two forearm second wheels 15 and multiple groups of forearm transition wheels 14, forearm connecting wheel 6 and forearm first wheel 11 are symmetrically arranged on both sides of forearm fixed plate 12, forearm second wheel connecting plate 16 is installed on On the other end of the forearm fixing plate 12, two forearm second wheels 15 are rotationally connected and installed on the forearm second wheel connecting plate 16, and the two forearm second wheels 15 are symmetrically arranged on both sides of the forearm second wheel connecting plate 16 , multiple sets of forearm transition wheels 14 are installed on the forearm fi...

specific Embodiment approach 3

[0014] Specific implementation mode three: combination Figure 1-Figure 5 and Figure 9 Describe this embodiment, a crawler robot with quick disassembly and assembly front and rear swing arms described in this embodiment, the forearm swing body 8 also includes a forearm hollow shaft 17, the forearm hollow shaft 17 is inserted into the forearm fixed plate 12 On one end, the forearm connecting wheel 6 and the forearm first wheel 11 are rotatably connected and sleeved on the forearm hollow shaft 17, and the forearm connecting wheel 6 and the forearm first wheel 11 are symmetrically arranged on both sides of the forearm fixing plate 12, and other specific embodiments Two same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com