Movable, liftable and telescopic belt conveying weigher

A technology of belt conveyor and belt conveyor, which is applied in the field of mobile lifting and telescopic belt conveyor scales, to achieve the effect of increasing the application range, ensuring stability, and solving the problem of fixed and non-movable positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

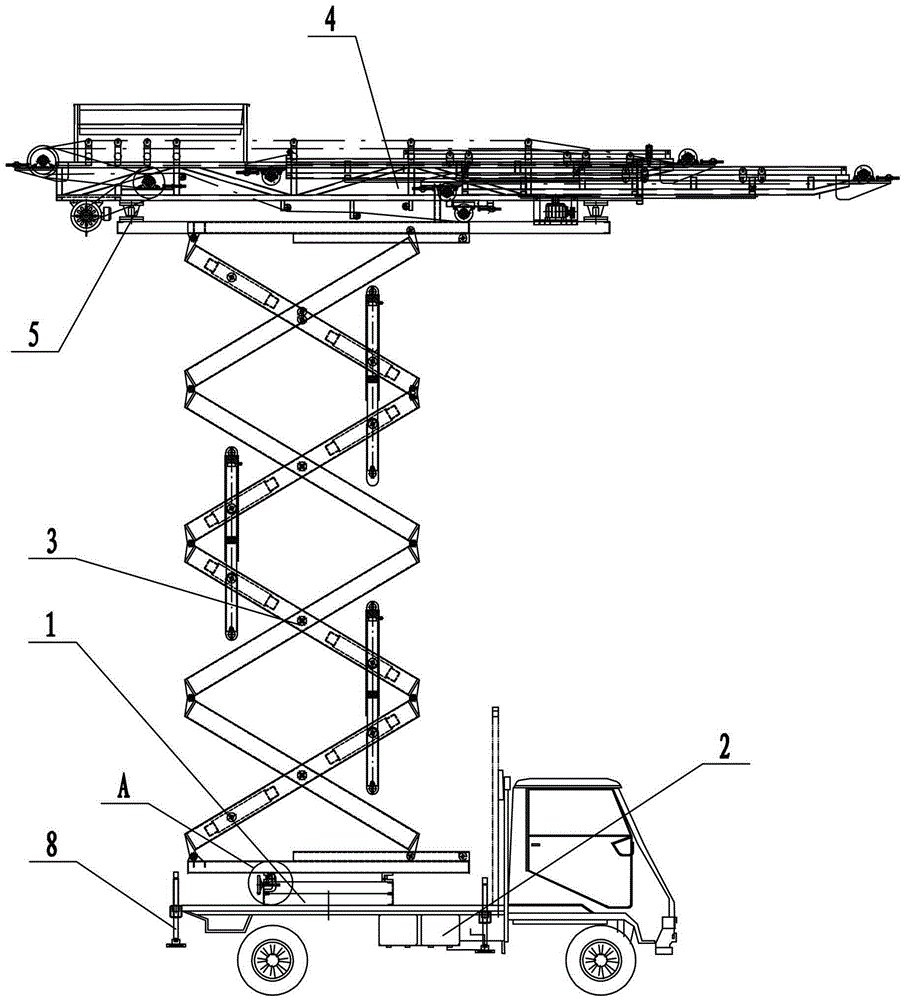

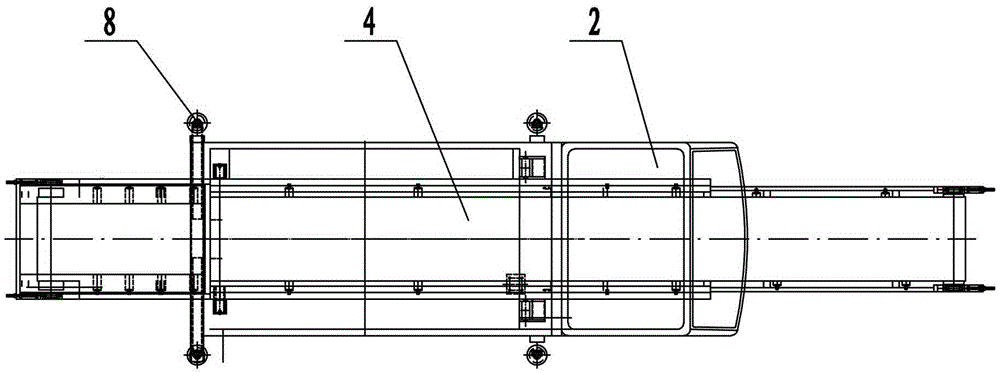

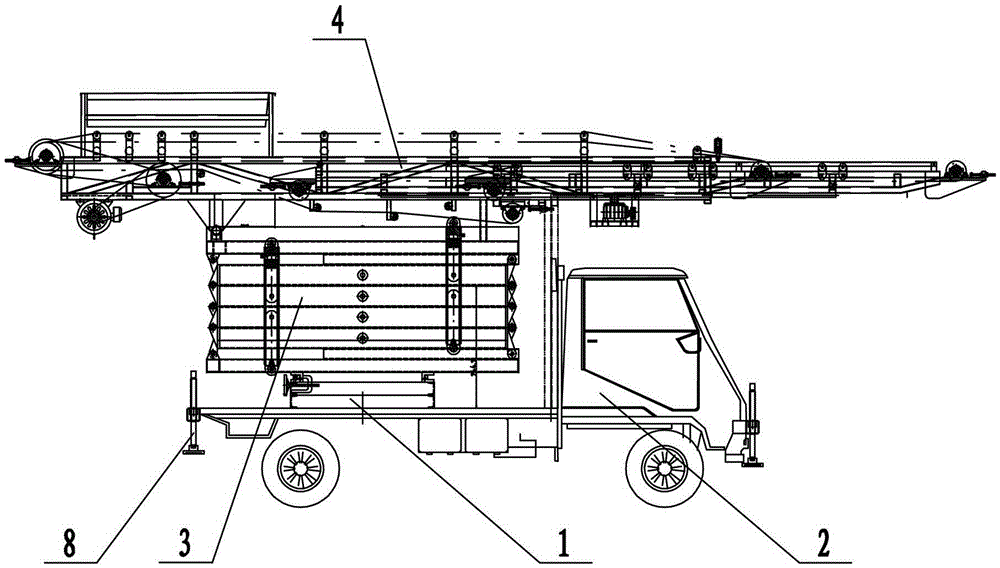

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a mobile lifting and telescopic belt conveyor scale includes a base 1, a moving mechanism 2, a lifting frame 3, a belt conveyor 4, and a sensor speed measurement weighing measurement system 5, and the lower end of the base 1 is fixed on the moving mechanism 2 Above, the mobile mechanism 2 is a motor vehicle, the base 1 is fixed on the motor vehicle, and the front and rear ends of the motor vehicle are provided with liftable outriggers 8, which can enable the positioning and stability of the mobile mechanism 2. The upper end of the base 1 is connected to the lifting The lower ends of the frame 3 are mutually rotatably connected by a rotating mechanism. The lifting frame 3 is a hydraulic lifting frame 3, and the rotating mechanism includes a lower ring 9 fixed on the upper end of the base 1, an upper ring 10 fixed on the lower end of the hydraulic lifting frame 3, and an upper ring 10 fixed on the lower end ...

Embodiment 2

[0034] Such as Figure 5 As shown, the first embodiment is repeated, with the following differences. In this embodiment, the lower end of the base 1 is fixed on the trolley 6, and the trolley 6 is pulled by the traction locomotive to move, so that the belt conveyor scale of the present invention can be moved. Scalable supporting legs 8 are arranged on the four corners of dolly 6, and tractor locomotive can be selected tractor or other manual machinery for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com