Automatic line distribution and collecting device

A technology of automatic wiring and wire take-up, applied in the field of wire take-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

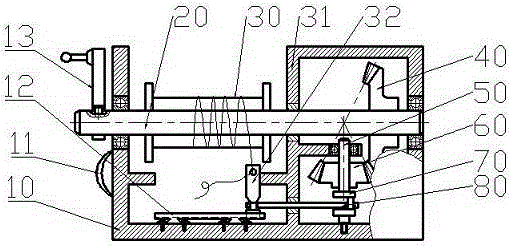

[0014] like figure 1 As shown, the automatic wiring take-up device includes: a base 10 , a take-up reel 30 , and a power shaft 20 . Two sidewalls of the base 10 are provided with symmetrical holes, and bearings are installed in the holes. A handle 11 is also installed on the outward side of the side wall of the base 10 . The take-up reel 30 is sleeved on the power shaft 20 and rotates with the power shaft 20 . Also includes driving helical gear 40, driven shaft 50, driven helical gear 60, eccentric wheel 70, connecting rod 80, wiring disc 32, chute 12; driving helical gear 40 is sleeved on the power shaft 20; driven shaft 50 Located below the driving helical gear 40, the driven helical gear 60 is sleeved on the driven shaft 50 and cooperates with the driving helical gear 40. An eccentric wheel 70 is connected below the driven shaft 50; the lower part of the eccentric wheel 70 is connected to the base 10 The bottom is hinged; the chute 12 is located below the take-up reel 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com